5

Installation

Plumbing

Anti-water hammer device should be provided as required.

Steam Outlet (15mm)

Do not install any valve in steam line. Flow of steam must be unobstructed.

Use 15mm brass pipe or copper tubing from unit to steam head as permitted by codes.

Insulate steam line using pipe insulation rated 120ºC or higher.

Pitch steam line 20mm per meter towards steam head or steam generator to avoid valleys and

trapping of condensate.

NOTE:

Running the steam line down and then up will create a steam trap blocking the

flow of steam.

Steam Head (15mm)

INSTALLER

Because the steam head and direct steam emissions are very hot,

locate the steam head where incidental contact by bather with the steam head or direct

steam emission cannot occur.

Locate steam head 150-300mm above floor, except for

• Tub/shower enclosures, install 150mm above tub top edge.

• For enclosures with acrylic or other non-heat resistant

flooring install Acrylic Shield.

Install steamhead with steam head facing downward.

Hand tightening is sufficient when teflon or equal pipe

thread sealing compound is used.

IMPORTANT:

To preserve steam head finish, do not

use wrench or other tools to tighten. Use no abrasive

cleansers or chemicals. Use only water with mild soap

and a non-abrasive sponge.

IMPORTANT:

Consult with supplier of acrylic,

fibergl s and other non-heat resistant enclosures

for recommended steamhead location.

Use an Acrylic Shield.

Drain (15mm)

NOTE:

A drain valve is provided to facilitate servicing. Provide a drain line connection from

steambath generator drain valve according to National and local requirements. Check local

plumbing code for receptor, trap and vent requirements. Unit drains by gravity.

Safety Valve (20mm

)

Where permitted by local codes, provide an outlet plumbing connection for safety valve.

1.

2.

3.

4.

5.

6.

7.

1.

2.

3.

4.

1.

2.

3.

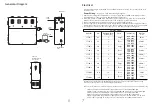

Steam Supply Pipe

Steam Head

13mm if not using

Acrylic Shield

19mm if using

Acrylic Shield

Fill in gaps

with silicone or a

sealant of the same

or better quality as

required to seal in

moisture.

Finished interior face

of steam room wall

Make sure to use

Teflon or a sealant

of the same or

better quality

on pipe threads.

Provide a 6mm

minimum clearance if

using an Acrylic Shield

(PN 103412).

See installation

instructions provided

with the Acrylic Shield.

!

WARNING

!

CAUTION

To insure proper and automatic safety valve operation: DO NOT connect

a shut off valve or a plug at safety valve outlet. DO NOT connect a shut off

valve in steam supply pipe.

4

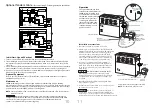

Locating the Steam Generator

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Select a location as near as practical to the steam room. Typical locations include:

closet, vanity cabinet, heated attic or basement.

Locate steambath generator within 7.5 meters of steam room.

NOTE:

The standard length of the cable for connecting the control to the steam generator

is 7.5 meters. The steam generator and control must be located accordingly.

Do not install steambath generator inside steam room.

Do not install steambath generator outdoors or wherever environmental conditions may

affect the safety and/or performance of the generator.

Do not install steambath generator or plumbing lines in unheated attic or any locations

where water could freeze.

Do not install steambath generator near flammable or corrosive materials or chemicals such

as gasoline, paint thinners, or the like. Installation in areas having high concentrations of

chlorine (such as pool equipment room) must be avoided.

Install steambath generator on a solid and level surface. Keyhole slots are provided on for

wall mounting. Insure the steam generator is properly secured and level when mounting

with keyhole slots.

Install steambath generator in an upright position only.

Install anti-water hammer device as necessary.

Provide a minimum of 300mm at both ends and top of the steam generator or as required

for servicing.

Provide unions as required to facilitate installation and disconnection of piping.

IMPORTANT:

Steam line, safety valve, drain valve, plumbing and steamheads become hot

during operation and remain hot after shutdown for a period of time. Provide appropriate

protection, including insulating plumbing lines. Avoid plumbing runs and steamhead

locations that can come in contact with bathers.

SAWO controls can be located inside the steam room or on the outside of the steam room.

NOTE:

SAWO Generators are CE compliant. Use only SAWO controls.

SAWO in-shower control

Temperature sensor

Control cable

Field installed

power supply

Provide unions as required to facilitate

installation and disconnect of piping

Steam generator

Valve

is shown

open

F

ield

installed

water

supply

pipe

Field

installed

steam

supply

pipe

NOTE:

For illustrative purposes only.

Consult with qualified designer, architect or

contractor for steam room construction details.

Steam Head

(shown with optional

acrylic shield)