7

1. When operated on 220V/1PH, kW output will be 84% of rated kW at 240V/1PH.

2. All three phase heating elements used on 380-430V/3PH products are rated at 415V/3PH.

3. When operated on 380V/3PH, kW output will be 84% of rated kW at 415V/3PH.

4. When operated on 430V/3PH, kW output will be 107% of rated kW at 415V/3PH.

5. Only copper field wiring suitable for 90 degree Centigrade-rated insulation is to be used.

6. For product operating on voltages in excess of 250V, use only 600V rated insulation.

Provide a power supply disconnect within sight of the steam generator or one that is capable of being

locked in the open position as permitted by applicable standards.

Wire sizes in this manual are indicative only, and should be used in conjunction with licensed electricians only.

1.

2.

3.

4.

5.

All electrical wiring to be installed by a qualified licensed electrician in accordance with local

electrical code.

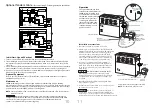

Power Wiring

- See page 8 "Field Power Wiring" diagrams.

Check power voltage. Use 220-240V to connect a single phase SAWO steambath generator.

Use 380-430V to connect a 3 phase SAWO steambath generator.

Use minimum 90ºC / 600V rated insulated copper conductors only, sized in accordance with

National Electrical Code and local electrical code for the Amps in Ampere Chart.

Connect suitably sized equipment earth wire to earth terminal provided.

Install a separate circuit breaker between supply and unit. Provide a power supply disconnect

within sight of the steam generator or one that is capable of being locked in the open position.

For single phase units, use two-wire supply source and equipment grounding wire.

Electrical

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

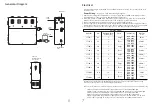

AMPERE CHART

Model No.

kW

Maximum Room

Volume (m³)

Phase

Wire Size

mm²

Current (A)

STS45-1

4.5

3

6.0mm²

4mm²

4mm²

2.5mm²

8.0mm²

2.5mm²

6.0mm²

2.5mm²

2.5mm²

4mm²

20A @ 380V

21A @ 415V

22A @ 430V

16A @ 380V

17A @ 415V

18A @ 430V

12A @ 380V

13A @ 415V

13A @ 430V

10A @ 380V

11A @ 415V

11A @ 430V

8A @ 380V

9A @ 415V

9A @ 430V

35A @ 220V

38A @ 240V

29A @ 220V

32A @ 240V

23A @ 220V

25A @ 240V

6A @ 380V

7A @ 415V

7A @ 430V

18A @ 220V

19A @ 240V

Three

Three

Three

Three

Single

Three

Single

Three

Single

Single

STS45-3

4.5

3

STS60-1

6.0

5

STS60-3

6.0

5

STS75-1

7.5

8

STS75-3

7.5

8

STS90-1

9.0

11

STS90-3

9.0

11

STS120-3

12.0

16

STS150-3

15.0

19

Generator Diagram

6

Water Inlet

Steam

Outlet

Safety

Valve

Manual Drain

Valve

Side view

showing element

access panel

Optional

Automatic Drain