SawStop 10” Contractor Saw 23

Assembling Y

our

Saw

18. Align the four holes in the belt guard with the four

screws on the pulley side of the motor. Use four M5

washers and four M5 hex nuts from the hardware

pack to mount the belt guard to the pulley side of the

motor (see Fig. 18). Use an 8 mm socket to tighten

the hex nuts.

Assembling Your Saw

Installing the Motor and Belt Guard

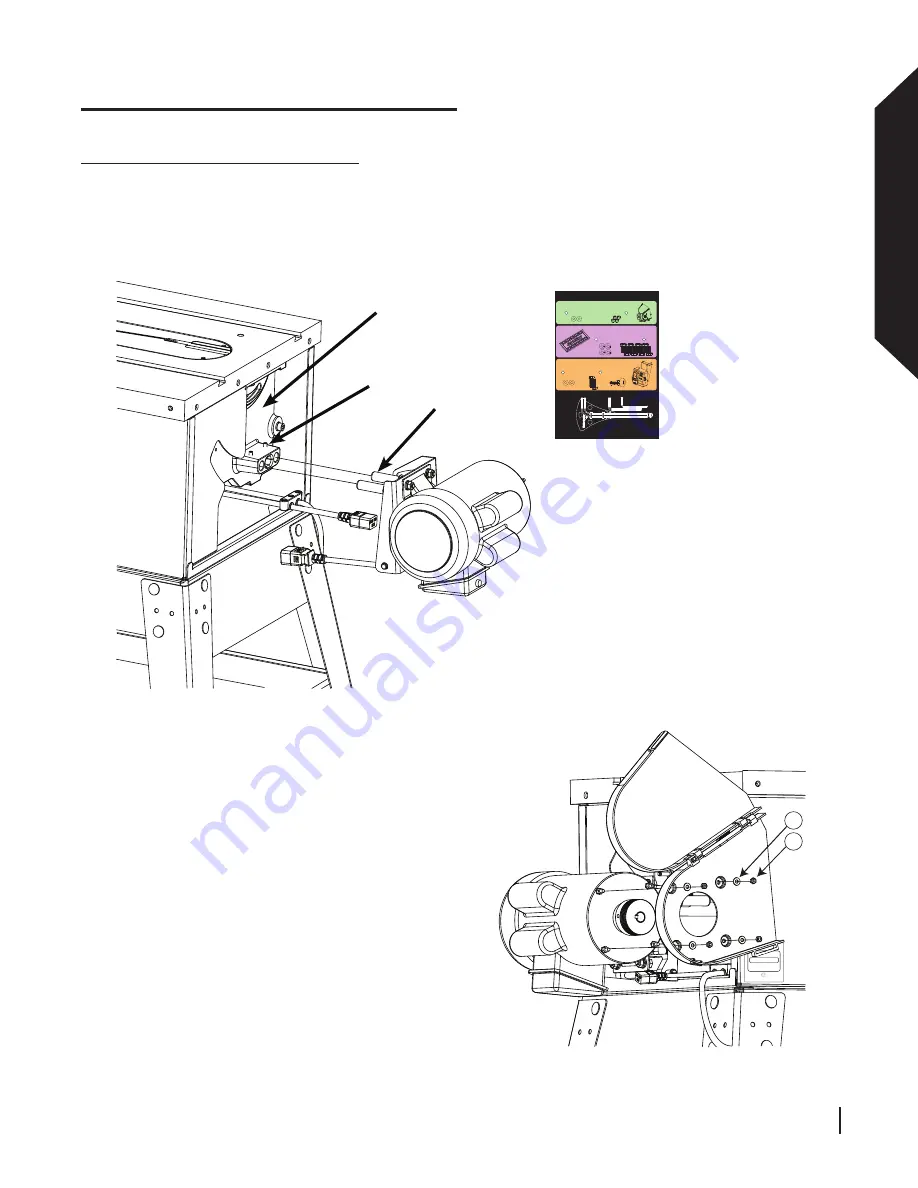

17. Locate the motor, the motor belt, the belt guard, and hardware pack #2. All of the hardware needed to install the

motor and belt guard is located in the area with the green background on hardware pack #2. Attach the motor

to the saw by sliding the motor mounting pins into the corresponding holes in the rear trunnion (see Fig. 17).

Make sure the pins slide all the way into the holes. Use the 3 mm hex key included with hardware pack #2 to

tighten the two lock down set screws to hold the motor in place.

Tools

Hex Key, M3

(1)

Hex Key, M5

(1)

Hex Key, M8

(1)

Mounting the Switch Box

Hardware for Step 22

Switch Box Keys

(2)

Washers,

M6 (2)

14

Hex Screws,

M6 x 20 (2)

15

Installing the Motor and Belt Guard

Hardware for Steps 17-19

Washers, M5 (4)

10

Hex Nuts, M5 (4)

11

Mounting the Extension Wings

Hardware for Steps 20-21

Lock Washers,

M8 (8)

12

Hex Screws,

M8 x 16 (8)

13

Hardware Pack

#

2

Blade Spacing

Adjustment

Gauge

(1)

Fig. 17

Fig. 18

lock down

set screws

mounting

pins

Made in Taiwan

SawStop, LLC

www.sawstop.com

TCP

actor Saw

Model No. CNS 175

Serial No. C074012345

Electrical / Electricidad / Électricité

115/230 Volts, 60 Hz

15/7.5 Amps

1 Phase

1.75 HP

3450 RPM

®

c

US

175370

11

10

rear trunnion