SawStop 10” Contractor Saw 65

Adjusting

Your

Saw

Lower Elevation Limit Stop

To check the position of the lower elevation limit

stop, turn the elevation handwheel counter-

clockwise until the blade is lowered all the way.

The top of the blade should be approximately

1

⁄

8

inch below the table top surface. If the

distance is approximately

1

⁄

8

inch, no further

adjustment is necessary.

If adjustment is necessary, the lower elevation

limit stop is fixed by the M6 socket head

screw on the bottom of the rear trunnion (see

Fig. 84). The head of the lower elevation limit

screw is painted yellow to make it easier

to locate. Loosen the M6 hex nut that locks

the position of the limit screw by rotating it

counter-clockwise with a 10 mm wrench. Next,

thread the lower elevation screw out counter-

clockwise with the included 5 mm hex key

at least two complete revolutions. Then turn

the elevation handwheel counter-clockwise

until the arbor slightly compresses the rubber

bumper (see Fig. 85).

The purpose of the rubber bumper is to absorb

the energy of the arbor block when the blade

retracts below the table upon activation of the

safety system. As shown in Fig. 85, the lower

elevation limit stop should be adjusted so that

the arbor block slightly compresses the bumper

at the lowest elevation. This should also ensure

that a 10 inch blade is at least

1

⁄

8

inch below the

top of the table.

Verify that the top of the blade is approximately

1

⁄

8

inch below the table top surface. Thread the

lower elevation screw in clockwise until it is

tight and then lock its position by tightening the

M6 hex nut against the rear trunnion. The lower

elevation limit has now been set.

Making Adjustments to Your Saw

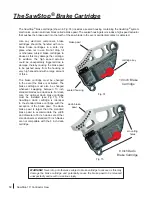

Fig. 84

rubber

bumper

arbor block

Fig. 85

lower elevation

limit stop

M6 hex nut