52 SawStop

®

10” Industrial Cabinet Saw

Making Adjustments to Your Saw

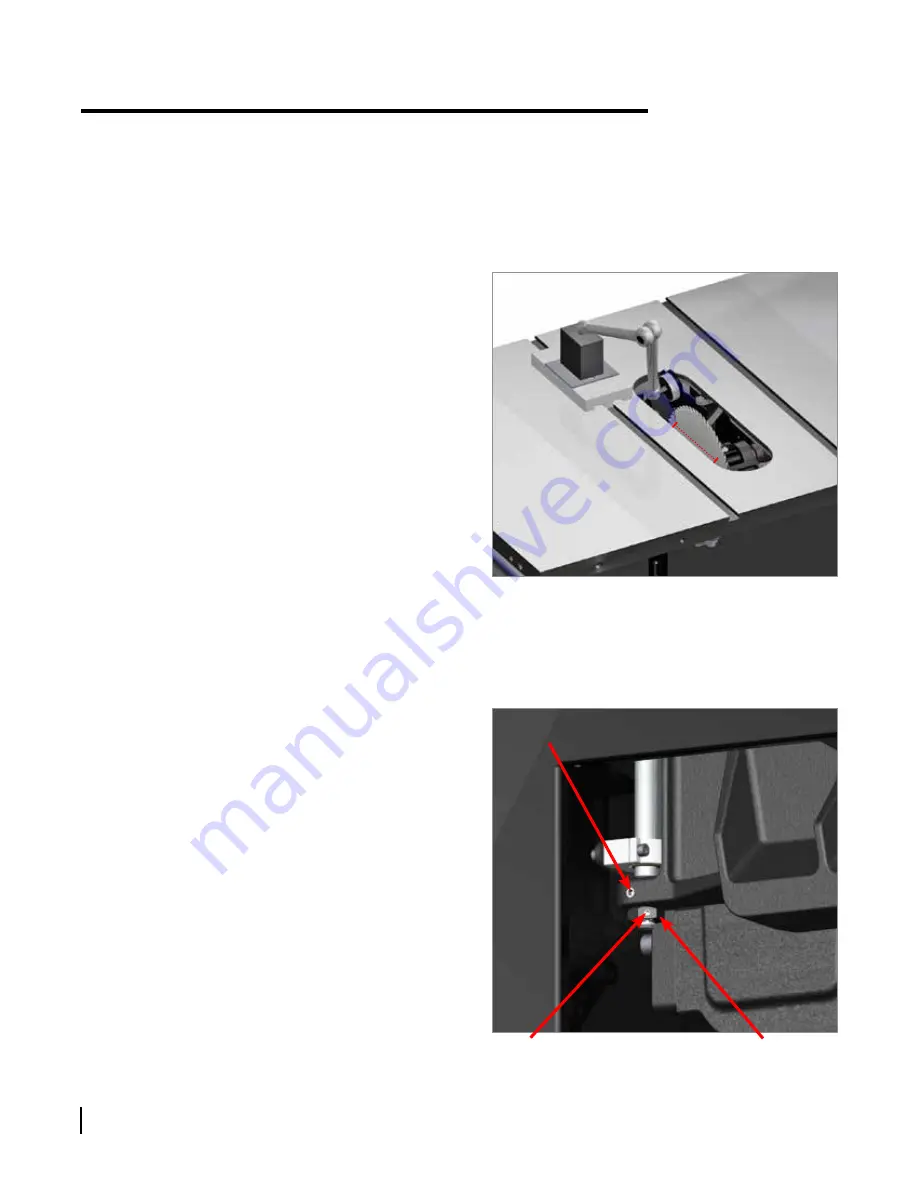

This procedure requires two measurements. For the first measurement, set the tilt angle to 0° and lower the

blade below the table. Make sure to back the hand wheels off slightly to release the pressure between the

trunnion assembly and limit stops. Next, position the dial test indicator near the right side of the blade. The

indicator measurement arm should rest against the blade approximately ½ inch inside the front edge of the

blade and about ½ inch higher than the top of the arbor washer (see Fig. 61). Depending on the geometry of

your dial test indicator, it may be necessary to position the indicator below the table.

Now measure the parallelism of the blade relative to the

miter slots in the table as described above in the section

named “Aligning the Table,” see page 47. If necessary,

adjust the alignment of the table so that the blade is

parallel to the miter slots when the blade is below the

table.

For the second measurement, raise the blade to the

maximum height above the table, making sure to back

the elevation hand wheel off slightly to release the

pressure between the trunnion assembly and the upper

elevation limit stop. Reposition the dial test indicator

so that the measurement arm is resting against the

blade approximately ½ inch inside the front edge of the

blade and about ½ inch higher than the top of the arbor

washer (see Fig. 54). Measure the parallelism of the

blade relative to the miter slots in the table as described

above.

If the second measurement is 0.002 inch or less, then the blade elevation assembly is aligned within the margin

of error for this measurement and, therefore, no further alignment is needed. If the second measurement is

greater than 0.002 inch, you can adjust the angle of the rear shaft relative to the front shaft to reduce the error.

The angle of the rear shaft is set by the eccentric

bushing at the bottom of the shaft (see Fig. 62). The

eccentric bushing is locked in place by a set screw in

the elevation plate, and a smaller set screw in the side

of the bushing.

To adjust the shaft angle, make sure the blade is still

about 3 inches above the table and the dial indicator

is still reading the second measurement (if not, repeat

the second measurement as described above). Next,

loosen the set screw in the elevation plate using a 4 mm

allen wrench and the smaller set screw in the eccentric

bushing using a 2.5 mm allen wrench. You can access

the set screws by opening the belt access door on the

left side of the cabinet.

Once the set screws are loosened, the eccentric

bushing should be free to turn. Using a 22 mm open-

end wrench or an adjustable wrench, turn the bushing

in either direction while watching the dial test indicator

Fig. 61

Fig. 62

eccentric

bushing

set screw

small set

screw