Next, move the fence to the right end of the tube and repeat the preceding process. Tighten the right-most M8 bolt that

mounts the tube to the front rail. Confirm that the left end of the tube is still correctly positioned by sliding the fence to

the left end of the tube. If the gap between the tube and rail on the left end has changed, loosen the left-most bolt and

readjust the position of the tube. Once both ends of the tube are adjusted correctly, tighten the remaining M8 x 16 hex

head bolts to lock the tube to the front rail. The fence should now slide smoothly along the tube without binding and

without excessive play when changing directions.

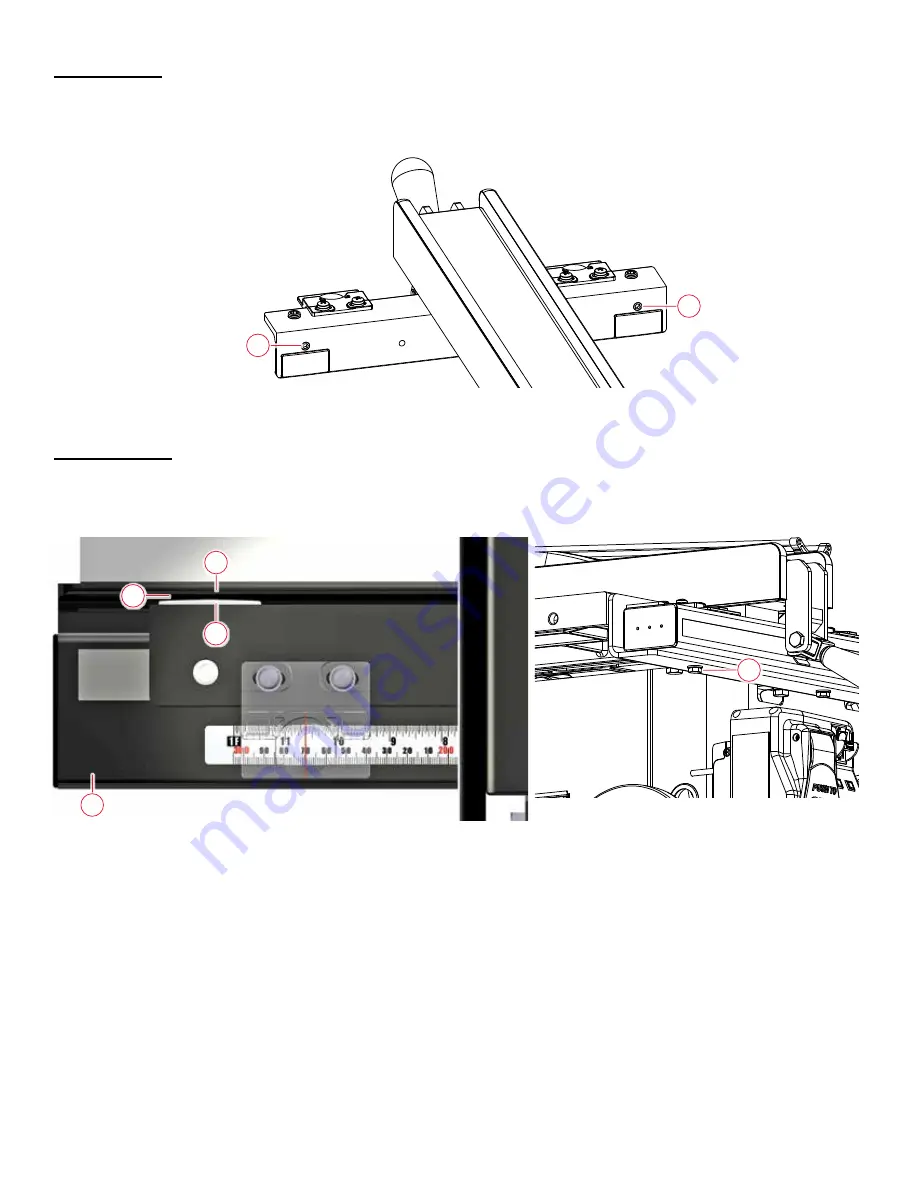

Locking Force:

If the fence is clamped but does not hold its position on the main tube, use a 5 mm hex key to turn both

parallelism adjustment screws (11) clockwise an equal amount to increase the pressure. The screws are located on the

back of the glide bracket (Fig. 27). If the handle requires too much force to clamp the fence to the main tube, turn the

adjustment screws counter-clockwise to reduce the clamping force.

Glide Clearance:

Once the fence is correctly clamped to the main tube (8), adjust the position of the left end of the tube

so that there is only a small gap (approximately 1/16”) (A) between the front rail (1) and the rear glide plates (10) on

the fence (Fig. 28). Tighten the left-most M8 x 16 hex head bolt (7) that mounts the tube to the front rail using a 13 mm

wrench (Fig. 29).

Page 12

|

SawStop T-Glide Fence System - Industrial Series II

Fig. 28

Fig. 29

Fig. 27

A

11

1

8

10

11

7