Sawyer Manufacturing Company

7799 S. Regency Dr., Tulsa, OK 74131 USA

F

918.834.0318

info@sawyermfg.com

P

918.834.2550

sawyermfg.com

V1.2

Operation

Operation

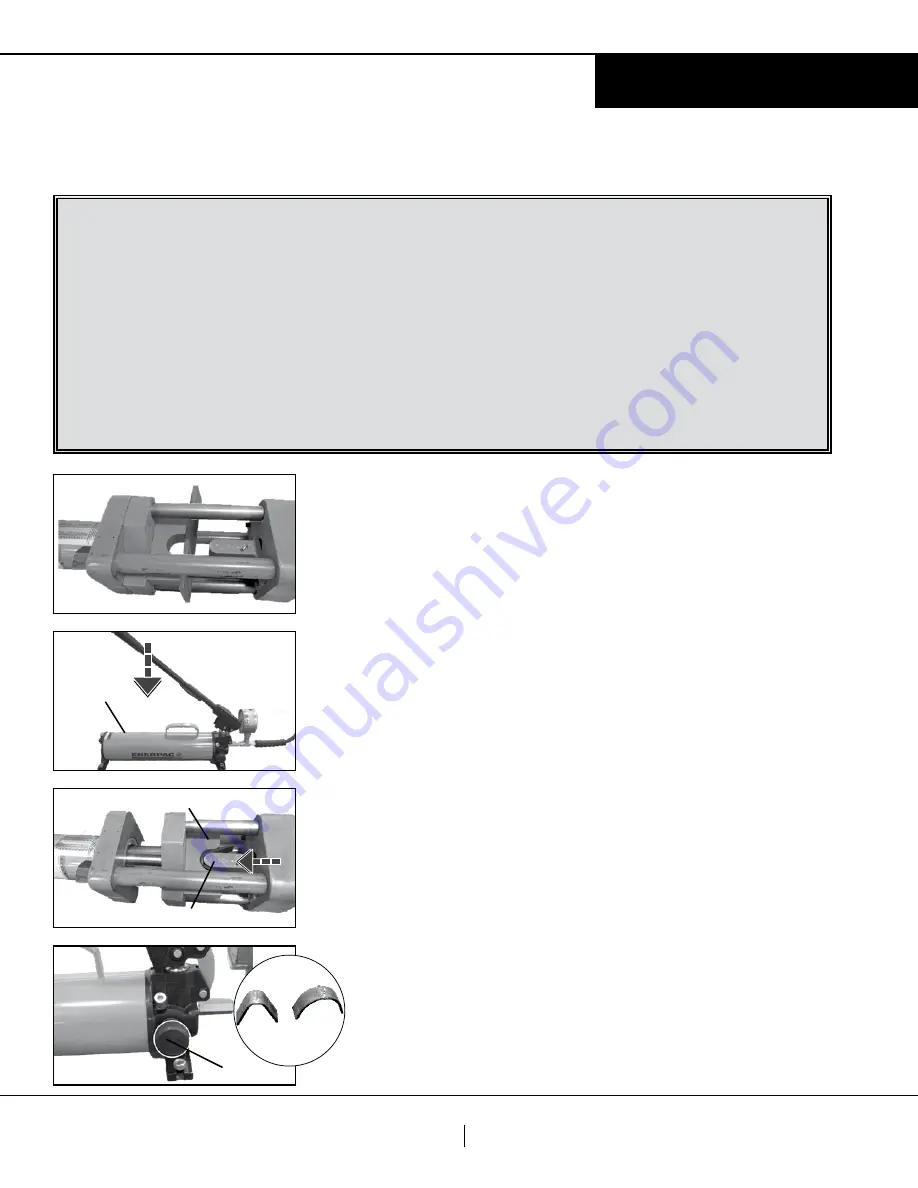

1.

Place coupon across supports of die.

(E, Fig. 5)

2.

Depress the ENERPAC pump.

(B, Fig. 6)

3.

Plunge

(D, Fig. 7)

the sample into the die.

(E, Fig. 7)

Note: A complete 180 degrees is recommended to complete the test.

4.

Release pressure via Hydraulic Relief Valve

(A, Fig. 8)

and

remove sample from die.

(E, Fig. 9)

Fig. 5

Fig. 6

Fig. 7

Fig. 8

E

B

D

Note: Refer to AWS, ASME and API specifications for bended coupon samples.

Tip: Mount hydraulic hand pump down to stable environment.

Tip: Hydraulic hand pump can be mounted vertically or horizontally.

Guided Bend Operation

Bend

This Bend test is designed to evaluate the quality of welds as a function of ductility in ferrous and nonferrous

products as evidenced by their ability to resist cracking during bending.

Reference:

3 Types of Bends:

A. Transverse side bend. The weld is transverse to the longitudinal axis of the specimen

which is bent so that either one of the side surface becomes the convex surface of the bent specimen.

B. Transverse face bend. The weld is transverse to the longitudinal axis of the specimen which is

bent so that the weld face becomes the convex surface of the bent specimen.

C. Transverse root bend. The weld is transverse to the longitudinal axis of the specimen

which is bent so that the weld root becomes the convex surface of the bent specimen.

Note: For more information please refer to the following publications:

AWS D1.2–D1.2M: 2003; API 5LC (R2006); API 1104 (R2010).

A

Fig. 9