Sawyer Manufacturing Company

7799 S. Regency Dr., Tulsa, OK 74131 USA

F

918.834.0318

info@sawyermfg.com

P

918.834.2550

V1.2

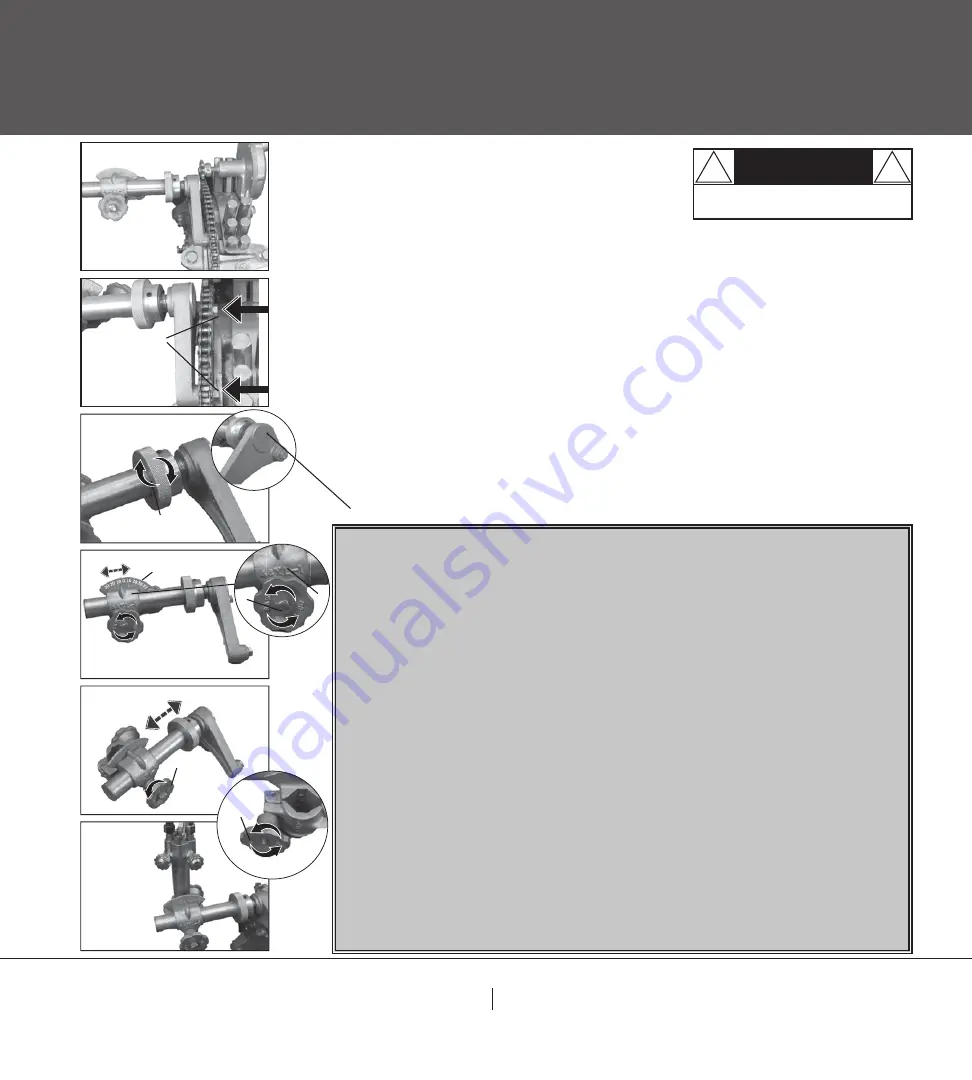

1.

Mount torch arm assembly to Compact

machine.

(Fig. 1)

A. Use 2 washers

(A)

, & 2 9/16” nuts.

(B, Fig.2)

Tip: Use 9/16” nut drive.

Note: Mount assembly using the 2 unthreaded holes on Compact machine.

Tip: Cycle Compact machine away from gearbox for easier installation.

Note: Model 284-A attaches to the out of round attachment not Compact machine.

*Please refer to the Compact manual for installaton of the Compact machine.*

1.

Loosen and tighten torch holder adjustment knob

(G)

to position

assembly on and off pipe.

(Fig. 3)

Tip: This screw is to adjust free motion of torch arm.

(Fig.4)

Torch Arm Setup

Tip: Place torch in torch holder to aide in setup.

1.

Bevel angle adjustment.

(Fig. 5)

A. Loosen bevel indicator set clamp screw.

(F, Fig. 6)

B. Adjust bevel indicator

(E)

to desired angle.

(Fig. 5)

C. Tighten bevel indicator set clamp screw.

(F, Fig. 6)

Tip: Use ½” wrench.

2.

Position adjustment.

(Fig. 7)

A. Loosen position adjustment knob.

(D, Fig. 7)

B. Move assembly to desired position.

C. Tighten position adjustment knob.

(D, Fig. 7)

3.

Install torch inside torch holder.

(Fig. 8)

A. Loosen torch holder adjustment knob.

(C, Fig. 9)

B. Install torch inside torch holder.

(Fig. 8)

C. Tighten torch holder adjustment knob.

(C, Fig. 9)

Installation

ADJUSTABLE TORCH ARM

Installation

Operation

CAUTION:

Refer to manufacturers

settings for safety settings.

!

!

CAUTION

Fig. 1

Fig. 9

J

F

G

E

D

C

*Please refer to the

Compact manual for

Operation of Compact.*

Fig. 4

Fig. 6

A,B

Fig. 2

Fig. 3

Fig. 5

Fig. 7

Fig. 8