Splitz-it 5-tON electric lOg Spliter

9

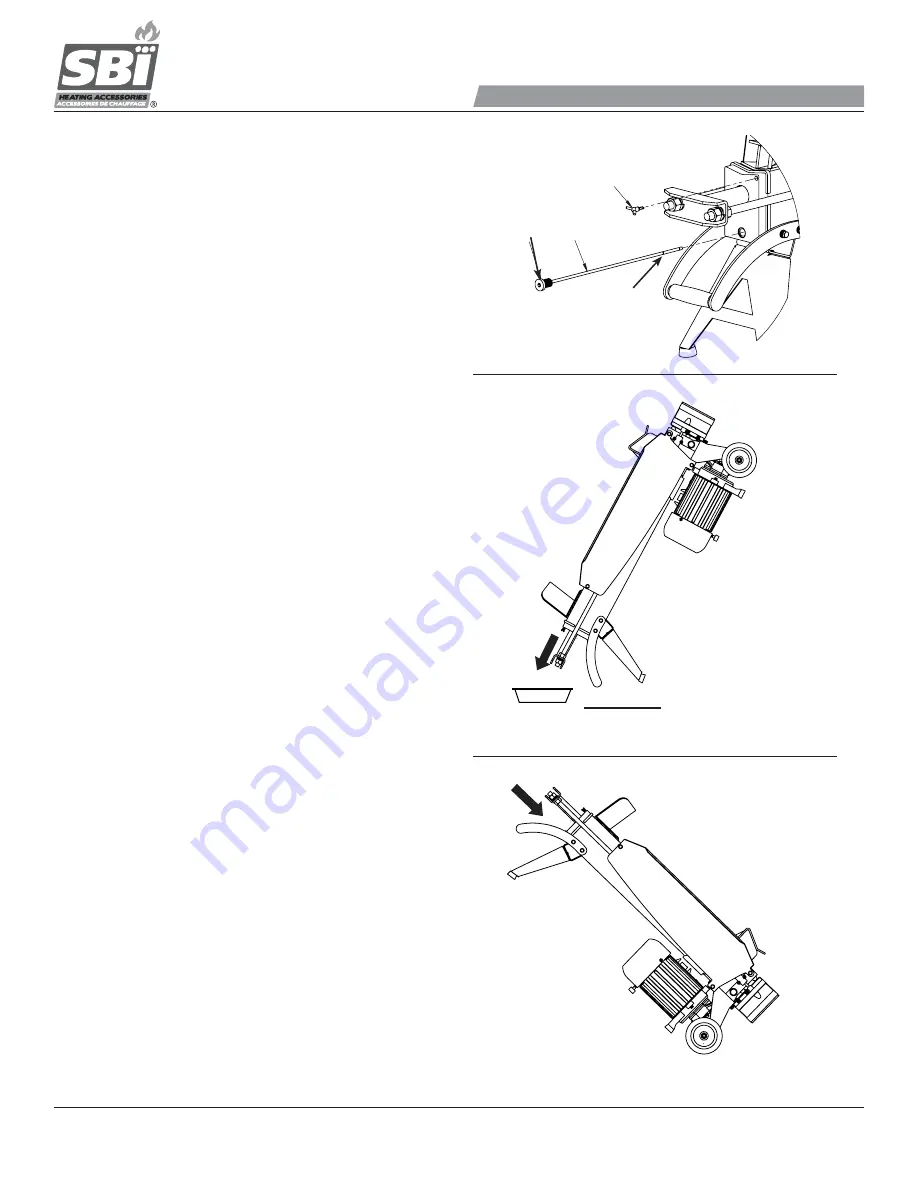

MAINTENANCE

REpLACING HYDRAULIC OIL

Replace the hydraulic oil in the log splitter after every 150

hours of use. Take the following steps to replace the oil.

1. Make sure all moving parts are stopped and the log

splitter is unplugged.

2. Remove oil drain bolt and dipstick. Make sure bleed screw

is closed tight.

(SEE FIGURE 9)

3. Turn the log splitter on the support leg side over using

a one gallon or larger capacity container to drain the

hydraulic oil.

(SEE FIGURE 10)

4. Turn the log splitter on the motor side.

(SEE FIGURE 11)

5. Refill with 3.75 quarts of fresh hydraulic oil.

6. While keeping the log splitter vertical, clean the surface

of dipstick on the oil drain bolt and put it back into the oil

tank.

7. Make sure the level of the refilled oil is between the two

grooves around the dipstick.

8. Clean the oil drain bolt before re-threading it back in.

Make sure the bolt is tightened to avoid leakage before

placing the log splitter horizontally.

IMpORTANT: LOOSEN bLEED SCREw 3-4 TURNS bEFORE

OpERATION.

Periodically check oil level to ensure it is between the two

grooves around the dipstick. If the level is below the lower

limit, fill until level is correct.

The following hydraulic oils, or equivalent, are recommended

for the log splitter’s hydraulic pump:

SHELL Tellus 22

MOBIL DTE 11

ARA Vitam GF 22

BP Energol HLP-HM 22

SHARpENING wEDGE

When the log splitter wedge becomes dull and/or worn,

sharpen the wedge using a fine-toothed file and smooth any

burrs or crushed areas along the cutting edge.

oil drain container

Figure

10

Figure 11

oil drain

plug

dipstick

bleed screw

Figure 9

full mark