Customer Helpline

1300 889 028

24

Maintenance

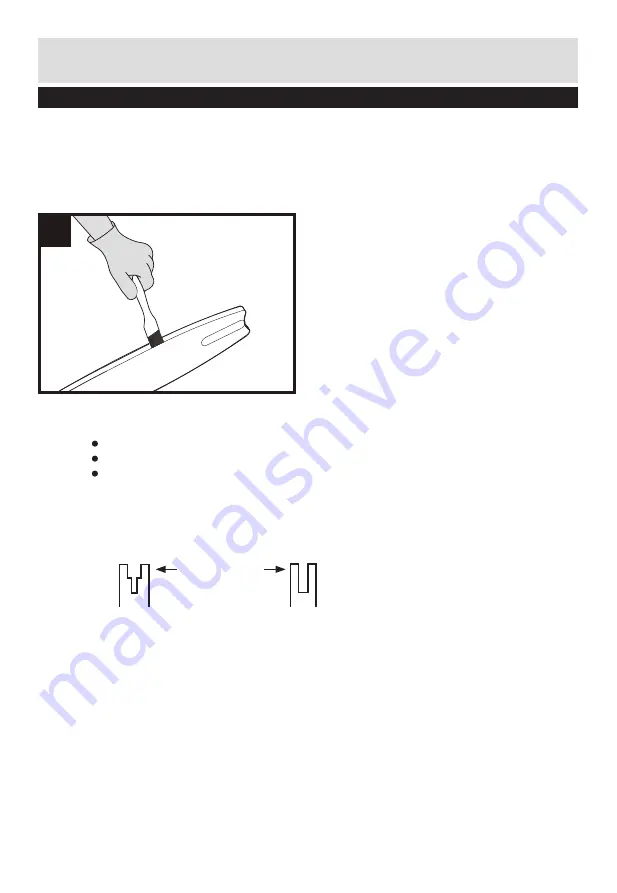

3. TO CLEAN THE BAR RAILS

1) Remove chain cover and bar and chain. (see section ASSEMBLY)

2) Using a wire brush, screwdriver or similar tool, clear the residue from the inner

groove of the bar. (See F)

3) Make sure to clean oil passages thoroughly.

Conditions which require chain and guide bar maintenance:

Saw cuts to one side or at an angle.

Saw has to be forced through the cut.

Inadequate supply of oil to the bar and chain.

Check the condition of the guide bar each time the chain is sharpened. A worn guide

bar will damage the chain and make cutting difficult.

After each use, remove the battery pack, clean all sawdust from the guide bar and

sprocket hole.

When rail top is uneven, use a flat file to restore square edges and sides.

File Rail Edges

and Sides

Square

Worn Groove

Correct Groove

Replace the guide bar when the groove is worn, the guide bar is bent or cracked, or

when excess heating or burring of the rails occurs. If replacement is necessary, use

only the guide bar specified for your saw in the repair parts list or on the decal located

on the chain saw.

4. REPLACING BAR & CHAIN

Replace chain when cutters are too worn to sharpen or when chain stops. Only use

replacement chain noted in this manual.

Inspect guide bar before sharpening chain. A worn or damaged guide bar is unsafe. A

worn or damaged guide bar will damage chain. It will also make cutting harder.

Fit the bar tensioning plate tab into the new bar by tightening the screw clockwise.

The tab protrusion (a) must be fitted into the bar hole. (See G)

a

F

H

G