EN

ZENITH-S

MP37634

ZP90993-1

49

4. SERVICING AND MAINTENANCE AND REPAIRING

Inspection and maintenance of this equipment shall be carried out by suitably trained personnel in accordance

with the applicable code of practice (e.g. IEC / EN 60079-17). During servicing, it is particularly important to

check those components upon which the type of protection depends.

4.1 ROUTINE MAINTENANCE

Routine maintenance is required in order to guarantee the efficiency of the enclosure and to maintain the required level of protection.

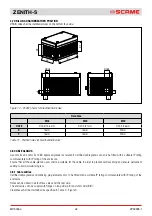

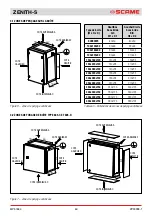

1) Check that the lid and removable flange seal is in place and not damaged each time the enclosure is opened

2) Check that all the lid and removable flange fixing screws are in place and secured each time the enclosure is closed

3) Check that the mounting screws/bolts are tight and free of corrosion

annually

4) Check the security of all cable glands

annually

5) Check the enclosure for damage

annually

6) In zones with presence of combustible dusts, it is necessary to periodically clean the upper surface of the box, limiting the

depth of the layer to less than 5 mm.

Note

, be sure to be tight the screws of lid and flanges with the torque indicated in this document.

Storage conditions :

Storage Temperature : from -50°C to +80°C

Relative Humidity : ≤95%RH

The estimated product lifetime is 20 years if maintenance and storage condition are respected and all prescriptions specified

applied in this instructions.

4.2 RESISTANCE TO CHEMICAL AGENT

Consideration should be given to the environment in which these enclosures are to be used to determine the suitability of these

materials to withstand any corrosive agents that may be present.

4.3 DISPOSAL

Disposal and recycling of the product shall be done according to national regulations for waste disposal and recycling.