A

NAVN:

STI:

DIMENSION:

MATERIALE:

DATO:

SIGN:

Krog Iversen & Co A/S

DK-5492 Vissenbjerg©

TG.NR:

EMNE:

C:\Working Folder\Designs\Scan 1003\91003037.idw

91003037

Justering af låge

22-10-2018

ken

Scan 1003-B

VÆGT:

AREAL:

N/A

N/A

0%-100%

0%-100%

B

NAVN:

STI:

DIMENSION:

MATERIALE:

DATO:

SIGN:

Krog Iversen & Co A/S

DK-5492 Vissenbjerg©

TG.NR:

EMNE:

C:\Working Folder\Designs\Scan 1005\91005014.idw

91005014

Tertiærkasse, luftindikator

19-03-2018

KEN

Scan 1005

VÆGT:

AREAL:

N/A

N/A

25

INSTRUCTIONS FOR USE

CB-TECHNOLOGY (CLEAN BURN)

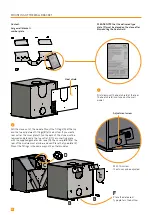

The stove is equipped with CB technology. In order to ensure optimal combustion of gases released during the combustion

process, air passes through a specially developed system of channels. The heated air is conducted into the combustion chamber

through the holes in the rear lining of the combustion chamber and at the baffle plates. This airflow is controlled by the rate of

combustion and cannot therefore be regulated.

NOTE: The wood must never be placed higher than the tertiary holes at the rear of the burn chamber (This does not apply at a

cold start).

BAFFLE PLATE

The baffle plate is located in the upper part of the combustion chamber. The plate holds back smoke, making sure it stays inside

the combustion chamber for a longer time before escaping through the chimney. This reduces the flue gas temperature as the

gases have more time to dissipate heat to the stove.

The baffle plate must be removed for sweeping; see “Maintenance”. Note that the baffle plate is made of porous, ceramic materi-

al, and is liable to break easily. You should therefore handle it with care.

The baffle plate is subject to wear and tear and not covered by the warranty.

PRIMARY AIR

The primary air regulation mechanism is used for lighting the fire, or to boost the burning process when you put wood on. The

primary air vent can be 0 - 60% open if you use hard wood fuel such as oak and beech. You can close the primary air vent if you

use soft wood such as birch or pine for fuel.

Settings for normal load: 0 - 60%

SECONDARY AIR

Secondary air is pre-heated and fed indirectly to the fire. At the same time, the secondary airflow cleans the glass pane to avoid

soot build-up. If you over-restrict the secondary airflow, soot can build up on the glass pane. The secondary airflow determines

the heat output from your wood stove.

Settings for normal load: 40 - 70%

Adjustment of air supply,

primary and secondary damper

Primary air

CB-technique

Primary air

Secondary air

Summary of Contents for 1004-B

Page 34: ...34 NOTES...

Page 35: ...35...