7

During the combustion, oxygen taken from the room air is

used. In order to get sufficient air supply for the combustion,

leave the windows half-open in well-insulated rooms or have

a fresh-air intake installed. It is very important that the air

is introduced in the room where the stove is installed. This

can be done in various ways. For instance, you can mount a

damper in the external wall as close to the stove as possible.

The damper must be so constructed that it can be closed

when not in use.

Most of the Scan stoves are prepared for an indirect external

air supply. The cover plate at the rear of the stove is to be

removed and replaced by the connection branch with damper

(Ø 100 mm - special accessory) that is mounted by means

of the self-tapping screws. Thereafter you can connect it with

a flexible tube.

Several Scan stoves are also available with a special air con-

tainer (accessory) that takes the external air and introduces it

directly into the combustion chamber. On certain models, this

container can be mounted afterwards.

The air channel must have a diameter of at least Ø 100 mm

and must be insulated for condensation reasons.

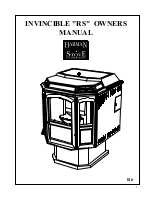

Direct air supply from the

bottom of the stove through

a concrete floor. Only pos-

sible on certain models and

not to be mounted after-

wards.

Direct air supply from the

rear of the stove through

an external wall. Can be

mounted afterwards on cer-

tain models.

The connecting piece/

damper for fresh-air intake

from the back of the stove is

mounted as shown above.

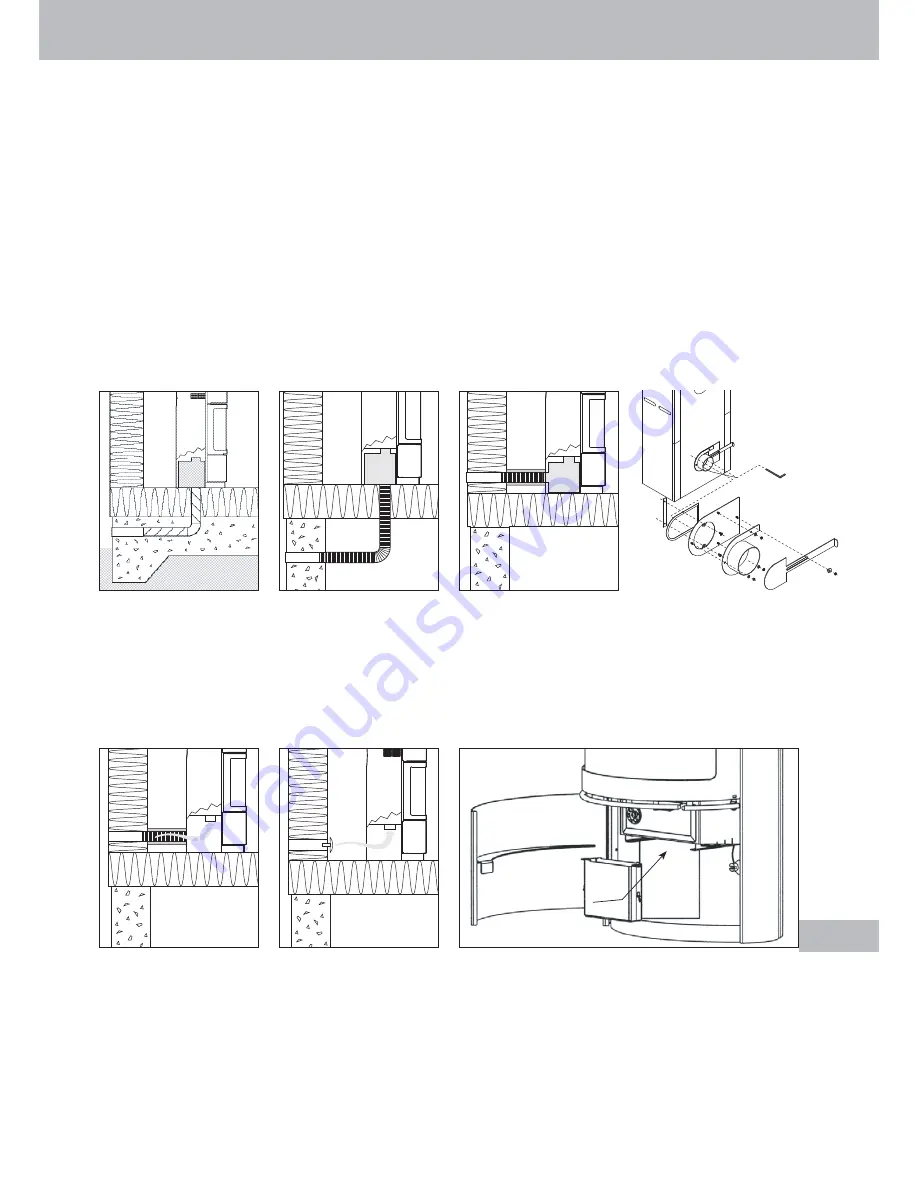

Indirect air supply from the

rear of the stove through an

external wall (by means of a

flexible tube).

Indirect air supply to the

room through a damper in

the external wall.

On certain models, this container can be mounted after-

wards if you need a direct external air supply into the com-

bustion chamber.

Direct air supply to the combustion chamber

Mounting of the connecting

piece/damper for fresh-air intake

Indirect air supply

Container for external air directly into the combustion chamber

Direct air supply from the

bottom of the stove through

a cellar. Only possible on

certain models and not to

be mounted afterwards.

Max. length ca. 3 m.

External fresh-air supply

M O U N T I N G I N S T R U C T I O N S