© Scania Industrial & Marine Engines

47

21. Every 1,200 hours:

CHECKING/ADJUSTING

VALVE CLEARANCE

Checking/adjusting valve clearance should be done after the

first 400 hours of operation.

Valves should be adjusted when the engine is cold, at least 30 minutes after

running.

Rocker cover gaskets should be changed as necessary. Tightening torque:

25 Nm.

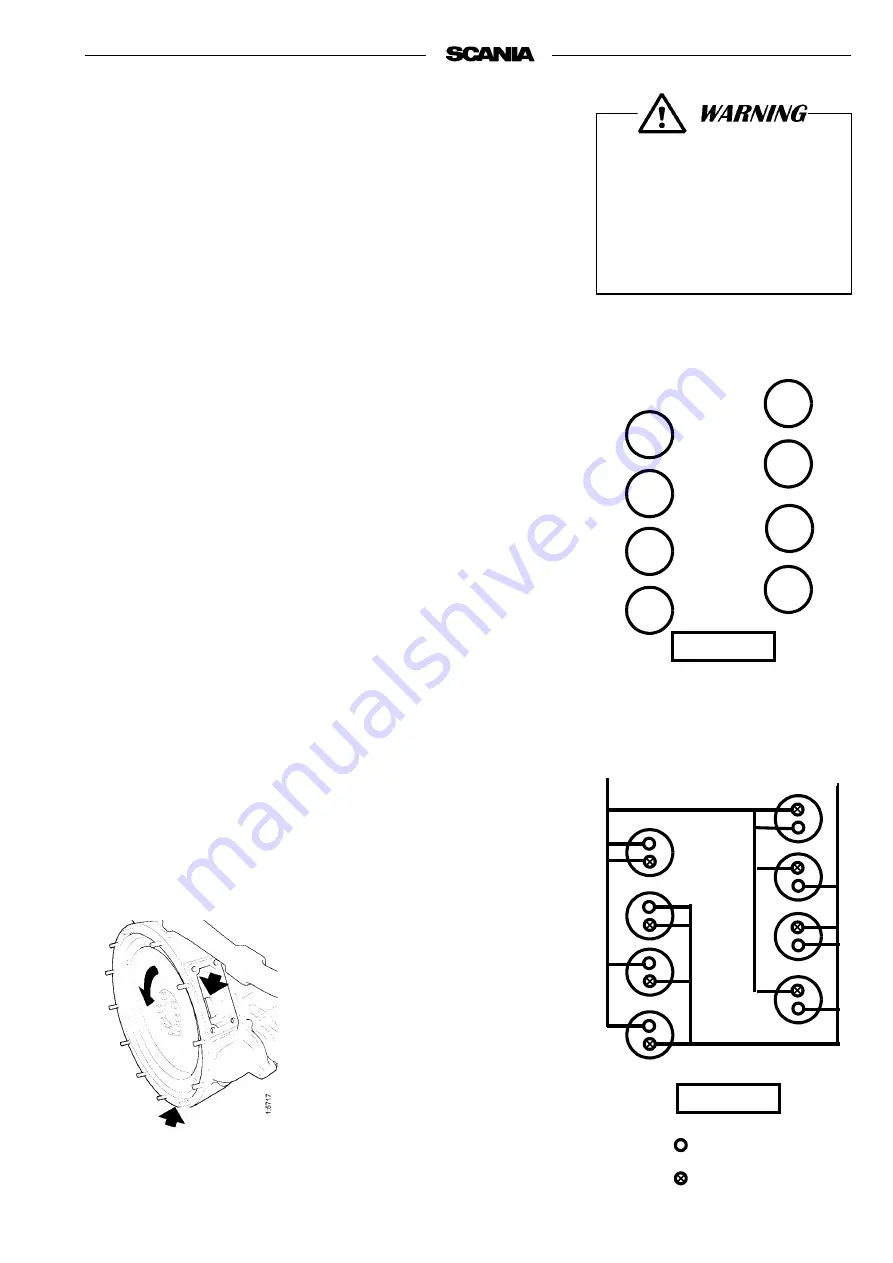

Alternative 1

- Turn the crankshaft in its direction of rotation until the piston in cylinder

No. 1 is 30°after TDC on the combustion stroke. There is a mark,

⊥

, at

this position.

- Adjust the following valves:

Right side

Cyl 1

Intake and exhaust

2

Ex

4

Ex

Left side

Cyl 5

In and ex

7

In

8

In

- Turn the crankshaft one revolution in its direction of rotation to the

⊥

mark. The piston in cylinder No. 1 will then be 30°after TDC on the

induction stroke.

- Adjust the following valves:

Right side

Cyl 2

In

3

In and ex

4

In

Left side

Cyl 6

In and ex

7

Ex

8

Ex

Covers for reading

on flywheel casing

Important.

On silumin housings, reading is possible

only from underneath.

On ductile cast iron housings, reading is

possible from underneath or from the

side (60°), depending on accessibility.

FLYWHEEL

No. 1 cylinder piston 30

°

after

TDC in

Intake valve

Exhaust valve

5

4

3

2

1

6

Cylinder numbering

FLYWHEEL

7

8

induction

stroke

combustion

stroke

WARNING

Immobilise the starting device

when working on the engine.

If the engine starts out of

control, there is a

SERIOUS RISK

OF INJURY.