44

© Scania Industrial & Marine Engines

CHANGING BATTERY

Removal

1.

Detach the negative lead (-) from the battery (cable to engine casing).

2.

Detach the positive lead (+) from the battery (cable to starter motor).

Fitting

1.

Connect the positive lead (+) to the battery (cable to starter motor).

2.

Connect the negative lead (-) to the battery (cable to engine casing).

18. Every 400 hours:

CHECKING THE COOLANT LEVEL

MONITOR

(optional equipment)

Note:

The level monitor should be checked when the engine is cold.

1.

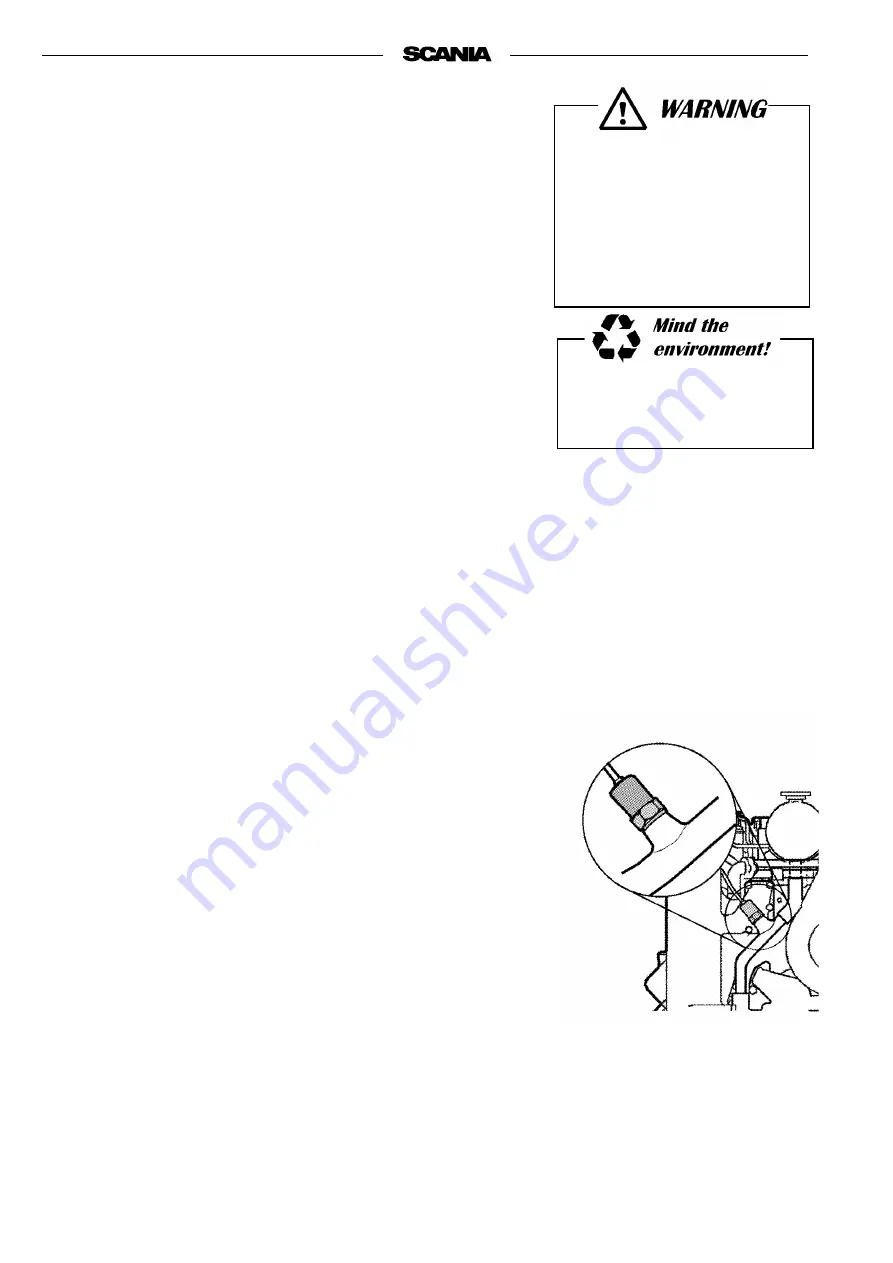

Undo the clamps on the level monitor’s lead to the wiring harness on the

engine and unplug the connector.

2.

Place a receptacle under the coolant pump and unscrew the monitor.

Immediately fit a plug with an M18x1.5 thread in the hole for the moni-

tor. Avoid getting the coolant on your skin.

3.

Plug in the monitor’s connector and set the control switch to ”ON”.

4.

Check that the indicator lamp remains on and that the buzzer sounds.

5.

Submerse the monitor in liquid in a metal receptacle (steel). It is impor-

tant to ensure that the body of the monitor is in contact with the metal.

6.

The indicator lamp should go out after about 2 seconds.

7.

Remove the monitor from the liquid. In about 7 seconds the indicator

lamp should come on and the buzzer start to sound.

8.

Unplug the monitor’s connector and screw the monitor back in place.

9.

Clamp the monitor’s lead as before and plug in the connector.

10.

Fill the system with coolant as described in the specifications on

page 32.

2-pole level monitor

Do not connect the cables to the

wrong terminals.

This could cause serious

damage to the electrical system.

If the terminals are short-

circuited, sparks will be

generated.

Dispose of used batteries

through an authorized waste

disposal contractor.