Document type

Document number

Rev

Page

Manual

66024

C

18 of 37

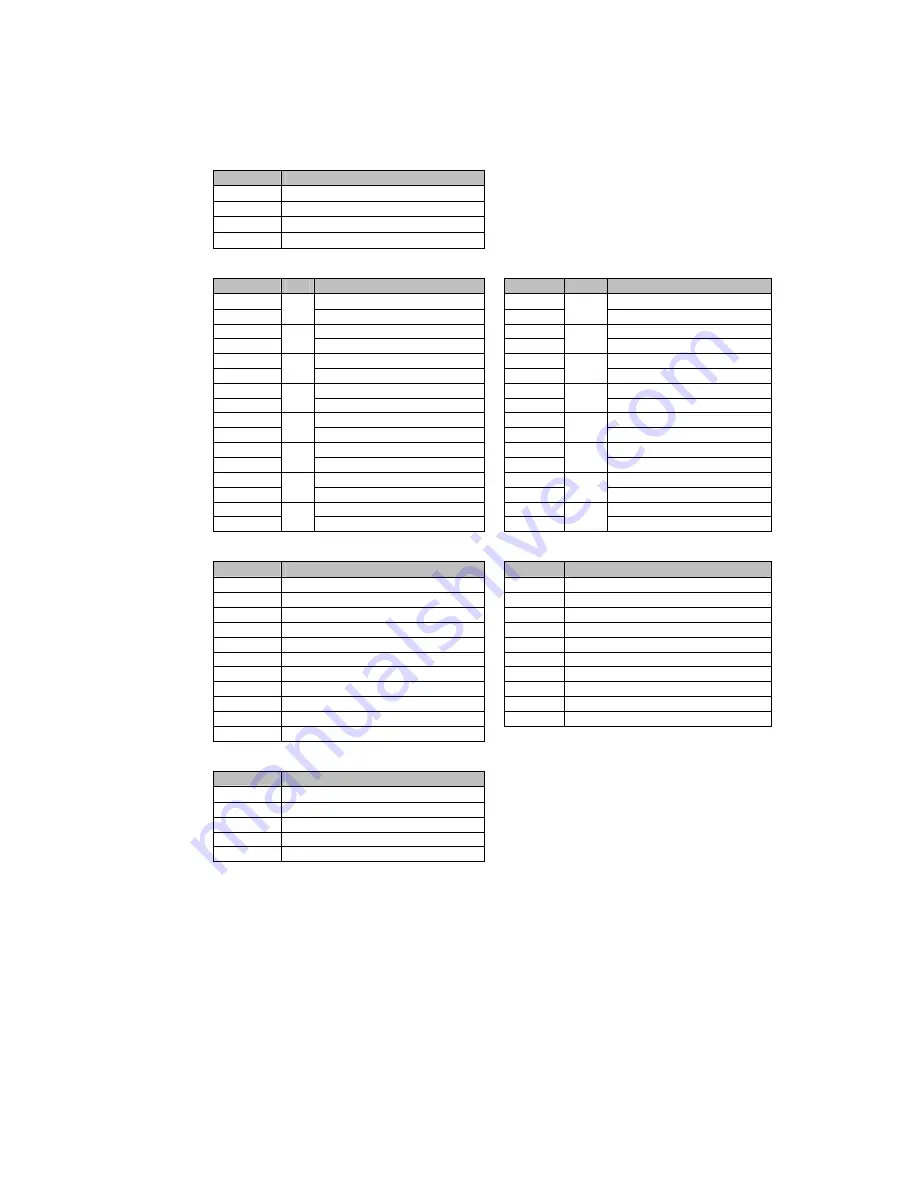

3.5.3

Terminal schematics for PWM type Central Unit

K7

Main

Pin no.

Description

K7.1

Supply (+12/24 VDC)

K7.2

GND

K7.3

DV +

K7.4

DV GND

K1

Analog outputs

K3

Analog outputs

Pin no.

No. Description

Pin no.

No.

Description

K1.1

PWM +

K3.1

PWM +

K1.2

1A

GND

K3.2

5A

GND

K1.3

PWM +

K3.3

PWM +

K1.4

1B GND

K3.4

5B

GND

K1.5

PWM +

K3.5

PWM +

K1.6

2A

GND

K3.6

6A

GND

K1.7

PWM +

K3.7

PWM +

K1.8

2B GND

K3.8

6B

GND

K1.9

PWM +

K3.9

PWM +

K1.10

3A

GND

K3.10

7A

GND

K1.11

PWM +

K3.11

PWM +

K1.12

3B GND

K3.12

7B

GND

K1.13

PWM +

K3.13

PWM +

K1.14

4A

GND

K3.14

8A

GND

K1.15

PWM +

K3.15

PWM +

K1.16

4B GND

K3.16

8B

GND

K4

EX1 - Digital outputs / inputs

K6

EX2 - Digital outputs / inputs

Pin no.

Description

Pin no.

Description

K4.1

Digital output 1

K6.1

On / Signal

K4.2

Digital output 2

K6.2

Digital output 7

K4.3

Digital output 3

K6.3

Digital output 8

K4.4

Digital output 4

K6.4

Digital output 9

K4.5

Digital output 5

K6.5

GND

K4.6

Digital output 6

K6.6

Digital output 10

K4.7

GND

K6.7

Digital output 11

K4.8

Digital input 1

K6.8

Digital output 12 / Digital input 4

K4.9

Digital input 2

K6.9

Digital output 13

K4.10

Digital input 3

K6.10

GND

K4.11

Input supply (+VDC)

K8

EX3 - Optional features

Pin no.

Description

K8.1

Customer specific

K8.2

Customer specific

K8.3

Customer specific

K8.4

Customer specific

K8.5

Customer specific

18/37

Summary of Contents for RC400

Page 1: ...Instruction Manual RemoteControlSystemRC400 Document 66024 Revision D Language English ...

Page 2: ......

Page 39: ......

Page 40: ......