7

2.3 Maintenance

Empty the spark box with regular intervals and control if the suction canals need a

cleaning. The dust bag has to be emptied after use. The contact wheel should be

replaced when the edges have been worn round or the tyre has been damaged.

The graphite pad on the surface grinding table is changed as required.

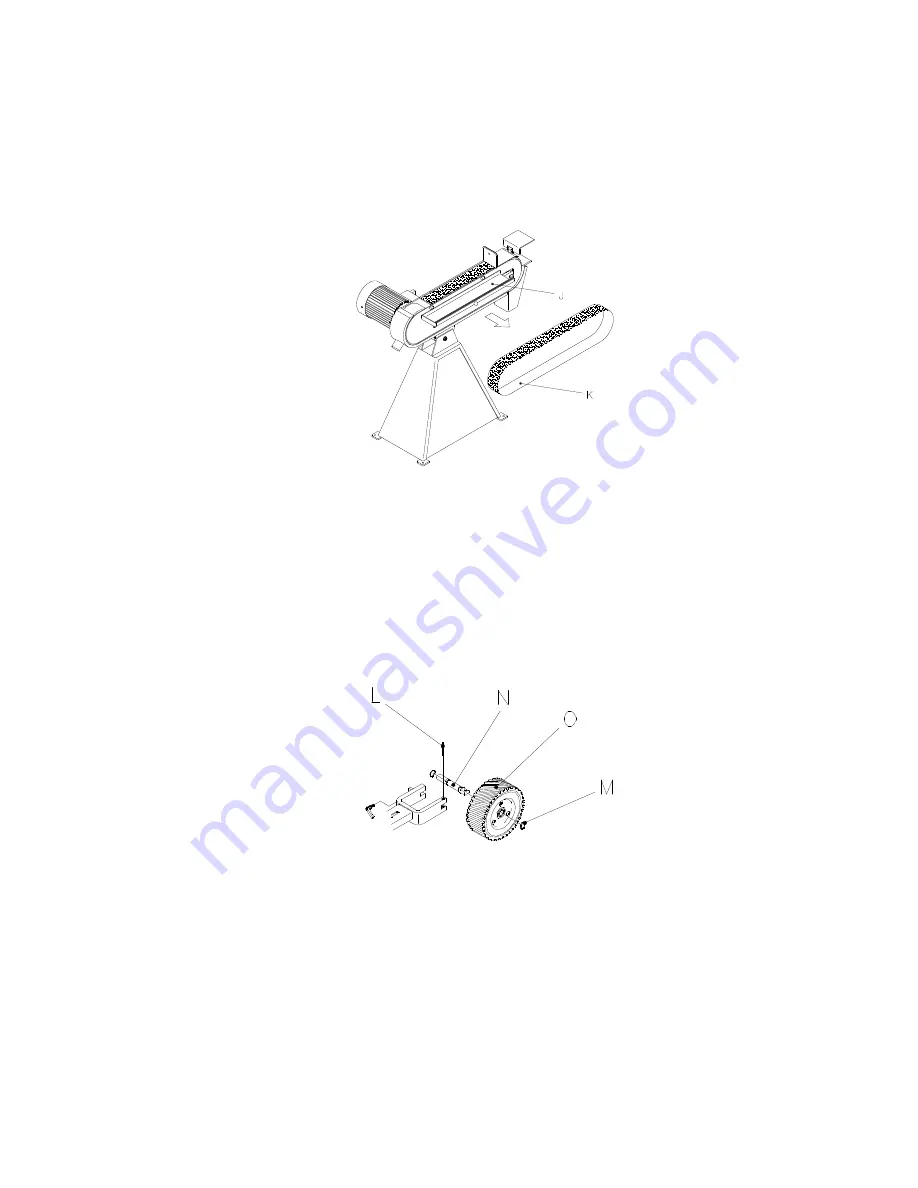

Fig.: 2.1

When changing the belt it is released by turning the handle (I) in anti-clock-wise

direction (see

fig.: 2.1

), the cover (J) is opened and the worn-down belt (K) is

removed by driving the belt against the direction of rotation, and the belt is

removed from the machine by the drive wheel. The new belt is fitted. It must be

checked that the direction of the arrows on the back side of the belt correpsond to

the direction of rotation. The handle (I) is turned clockwise until grinding belt is

tightened. Check for alignment by turning the grinding belt by hand and adjust with

handle (D)

Fig.: 2.2

To change the contact wheel remove the grinding belt, tool rest and spark

arrester. Use a 6 mm mandel to hammer out the pin (L). Now the contact wheel

with axle and bearings can be taken out. One of the lock rings (M) and the axle

(N) can be taken out. The new contact wheel (O) is fitted in in reverse order.