COMPACT 75

COMPACT 75

Operator’s manual for drilling machine

- 14 -

Types of a ground material

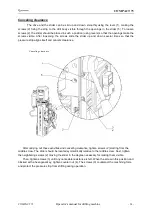

As shown on the graphs (Drawing 4) magnetic clamping force of the electromagnetic base to the

ferromagnetic ground depends on its magnetic properties. Steel with increased carbon content and

some other alloying ingredients has lower magnetic permeability, what causes a decrease in the

clamping force. Also a thickness of a work piece, on which the drill is placed, is significant.

Maximum clamping force of the electromagnetic base to a 5 mm thick work piece

surface is only about 25% of a clamping force obtained from a smooth, plane, and 22

mm thick standard plate.

If such thin ground material does not bow, one can try to carry out drilling of a

hole, although with keeping the strictest precautions. Particularly a magnitude of a

pushing force on a feed handle should be very limited.

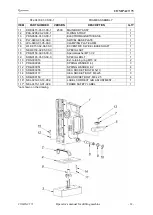

Appropriate rpm should be adjusted depending on if drilling would be carried out with a drill bit, or

with trepan type metal cutter and a metal cutter’s diameter. A drive is equipped in mechanical 2-step

reducing gearbox of a motor rpm. A general dependence between drilling diameter and drilling speed

is shown in graphs (drawing 5), detailed guide is supplied by manufacturer of used drilling tools. The

graph is just a general guide and the shown dependence applies to average structural steel.

Cooling agent is fed gravitationally from a coolant bottle through an arbor to an inside of the metal

cutter. For on-a-wall and on-a-ceiling positions special cooling pastes have to be used.