COMPACT 75

COMPACT 75

Operator’s manual for drilling machine

- 21 -

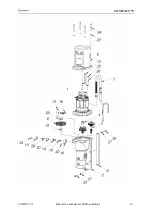

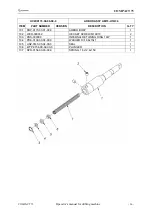

Tapping

1.

Prepare the drilling machine for tapping (see point

2. Put the tap along with the hole-axis.

3. Set the direction of rotation and the value of rotational speed of the spindle corresponding

to the size of the tap (see Drawing 5)

4. Place the lubricant on the working part of the tap - it will prevent seizure and extend

operating life.

5. Start the rotation and produce the tap by carefully turning the levers.

6.

Stop the rotation by the switch (02) and change the direction of rotation by switch (05).

7. Start the rotation and carefully put the tap outside the hole.

8. Stop the motor.

9. Replace the tap to no. 3 size, change the direction of rotation and repeat activity from

point 4 to 8.

The machine allows making threading to the extent specified in the technical data. To perform

tapping is recommended to use threads for hand-threading No. 1 and No. 3.

Thread must be made in two operations.

During drilling holes: is recommended to pay special

attention to the selection of hole diameter.

Too small diameter hole: threading process may be

impossible to do due to excessive cutting resistance and the associated lack of power.