COMPACT 75

COMPACT 75

Operator’s manual for drilling machine

- 24 -

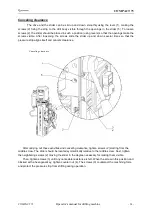

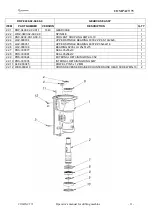

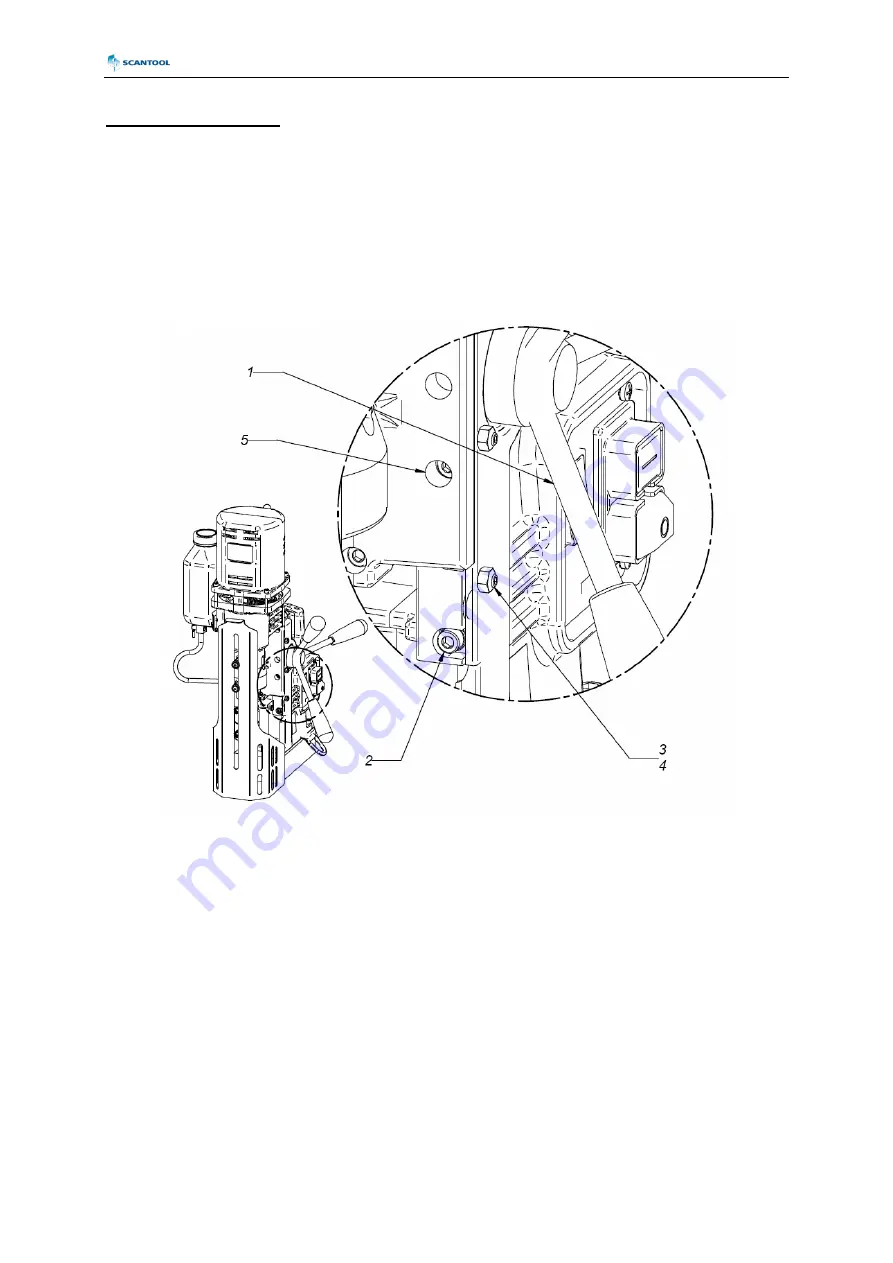

Canceling clearance

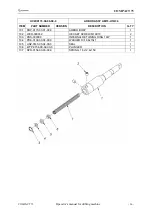

The drive and the slider can be slid up and down smoothly using the lever (1), making the

screws (2) fixing the strip to the drill body visible through the openings in the

slider (5). To loosen

screws (2), the slider should be placed in such a position (using levers) so that the openings make the

screws visible. After loosening the screws slide the slider up and down several times so that the

pressure strip aligns itself and cancels clearance.

After carrying out these activities and canceling clearance, tighten screws (2) starting from the

middle screw. The slider should be located symmetrically relative to the middle screw. Next, tighten

the neighboring screws (2) m

oving the slider in the degree necessary for making them visible.

Then, tighten screws (3) until any noticeable resistance is felt. When the screw in this position and

blocked with a hexagonal key, tighten counter nut (4). The screws (3) counteract the mac

hining force

and protect the pressure strip from shifting during operation.

Canceling clearance