How to adjust

1

• If access is not already available, remove the lamp cover

A

, back cover

B

, right

hand end plate

C

and right hand drum cover

D

, (section 4•2 steps 1-4).

2

• Remove the two 2.5 mm countersunk screws from each side of the hardware

unit and carefully slide the unit partially out.

3

• Insert the back plane extender onto connector J1 on the driver board and care-

fully push the hardware unit back in.

4

• Fit a terminator to a SCSI connector on the scanner and SCSI cable and RS 232

service cable to the scanner and PC.

5

• Set the Dip switch to 8, (on).

6

• Cover the side of the heat sink on the driver board, (see the “caution” on the

previous page).

7

• Turn on the PC or Mac and scanner and start up Photoshop plug-in.

8

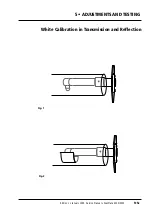

• Carry out a white calibration in transmission (section 5•5).

9

• Access the service program main menu (section 3•5).

10

• Lock the drum by pressing

Lock drum

on the indicator display.

11

• Remove the drum and mount the focus motor adjustment tool (fig. 1) onto the

drum platform.

Note: do not

rotate the drum platform while the adjustment tool is fitted.

12

• Remove the 3 mm set screw securing the optics holder to the sensor lens and

remove the holder (fig. 1).

13

• From the service program main menu, select

H

, (

Set focus to zero

).

14

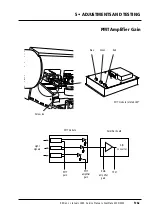

• Loosen the two 3 mm allen screws

B

(fig. 2) securing the focus motor to the

sensor. The motor will now move to the rear under spring pressure.

15

• From the service program main menu, select

1

, (

Move drum Z/P/L/.

), then

.

,

(“dot” allows setting your own drum position parameters) and move the drum

spindle until the adjustment tool is directly in front of the sensor.

16

• Push the focus motor towards the drum tool until the sensor head and tool

touch. The tool should now rotate with light resistance from the sensor head.

17

• Maintain the pressure on the focus motor and tighten the two 3 mm allen

screws

B

on the focus motor. (Recheck the resistance on the adjustment tool

after tightening the screws).

18

• Select

1

, (

Move drum Z/P/L/.

), then

L

to move the drum back to the lock posit-

ion and remove the adjustment tool.

19

• Refit the optics holder and tighten the 3 mm set screw.

20

• Make a focus calibration from photoshop plug-in.

21

• Press

Alt

+

Option

in plug-in and read the step values

or * Show scanner opti-

ons

in the service program can be selected and focus values for drums 0-9 will

be shown, together with barcode reading information.

22

• Check that these values are within the tolerances of the graph (fig. 3) by read-

ing the diameter on the drum flange.

23

• Remove the cover over the driver board heat sink.

24

• Remove the driver board extender, push the hardware unit fully in and refit

the two 2.5 mm countersunkscrews on either side of the unit.

25

• Refit the covers removed in step 1 in accordance with section 4•2.

Service Manual • ScanMate 4000/5000 Edition 1

•

January 1996

Focus

5•3b

Summary of Contents for ScanMate 4000

Page 1: ...ScanMate 5000 ScanMate 4000 ...

Page 6: ......

Page 16: ......

Page 18: ......

Page 20: ......

Page 22: ......

Page 24: ......

Page 28: ......

Page 40: ......

Page 44: ......

Page 48: ......

Page 52: ......

Page 56: ......

Page 60: ......

Page 64: ......

Page 68: ......

Page 72: ......

Page 76: ......

Page 80: ......

Page 84: ......

Page 88: ......

Page 92: ......

Page 96: ......

Page 100: ......

Page 102: ......

Page 106: ......

Page 110: ......

Page 114: ......

Page 118: ......

Page 122: ......

Page 126: ......

Page 130: ......

Page 134: ......

Page 138: ......

Page 142: ......

Page 146: ......

Page 150: ......

Page 154: ......

Page 156: ......

Page 162: ......

Page 164: ......

Page 170: ......

Page 171: ...ScanMate 4000 Type 250 Circuit Connection Diagram ...

Page 172: ...ScanMate 5000 Type 210 Circuit Connection Diagram ...

Page 174: ......