SCARAB M6 SWEEPER KIT

21

Operator’s Manual

Amdt.1 - 03 November 2009

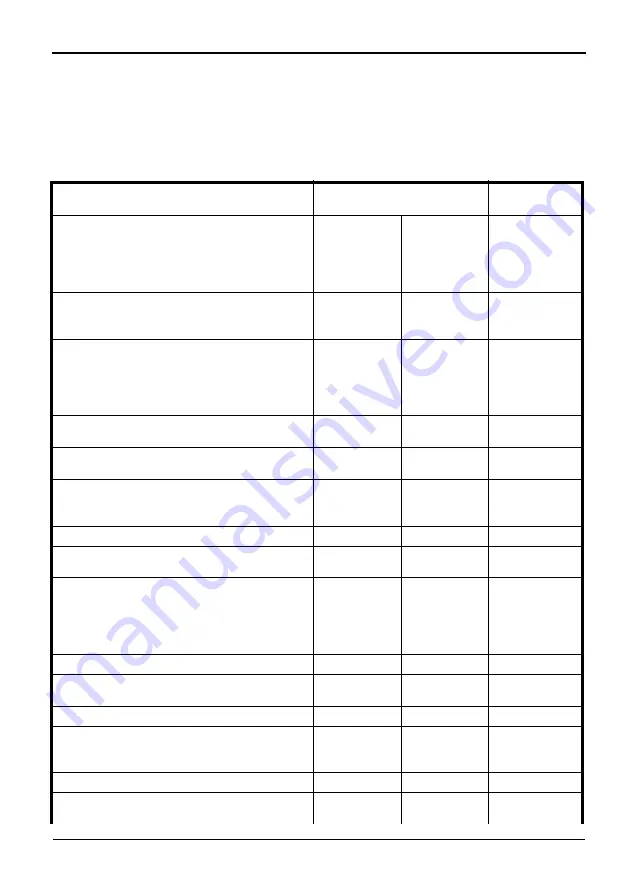

RECOMMENDED OPERATOR’S ROUTINE MAINTENANCE

It is important that the following routine maintenance procedures are

carried out as directed. This will help to ensure that your Scarab Sweeper

performs at the optimum level of safety and efficiency. Refer to the

paragraphs immediately following this schedule and to the

Table of Contents (Page 2) for more detailed information.

MAINTENANCE PROCEDURE

DAILY ACTIONS

BEFORE USE

R

AFTER USE

WEEKLY ACTION

Check vehicle / body for safety. All lighting

equipment, tyres, fuel, oil, coolant, brake

fluid, windscreen wash and water-tank

levels. Rectify in line with manufacturers

specifications or report fault as appropriate.

Check auxiliary engine as follows: fuel, oil

and coolant levels. Rectify or report as

necessary.

Check hydraulic oil level and inspect

vehicle for signs of hydraulic leaks, including

the pumps and hoses mounted on the

auxiliary engine. Check oil cooler and

radiator are clean. Rectify as necessary.

If vehicle not previously used by YOU,

check suction fan is clean. Rectify or report.

Check brushes/skirts for wear. Remove any

entangled items, e.g. lengths of string

Check suction nozzle/flaps for damage/

correct ground clearance. Wrong settings

will degrade suction performance.

Check water spray jets for blockages.

Check all equipment is stowed and brushes

have been raised.

Wash vehicle, particularly hopper screens,

surrounding ledges and area above

screen. Leave hopper door partially open

for air to circulate. Avoid directing high-

pressure water at electrical connections.

Wash oil cooler, ensuring that fins are clean

Lubricate as appropriate, all brush links,

pivots and nozzle wheels.

Remove and clean the water strainers

On reduction gearbox equipped

machines, grease prop. shafts and check

for wear at the U/Js.

Grease the Hopper Ram (Top & Bottom)

Visually check entire machine for wear/

damage. Rectify or report as required