4 •

E-649RA

- User Manual

EN

FR

IT

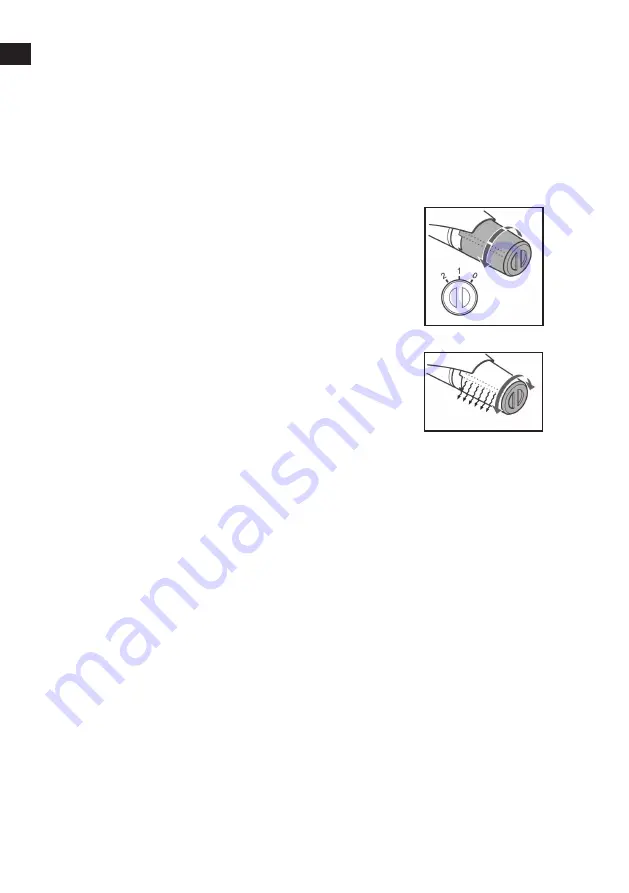

1. Mounting the mandrel container:

Push the mandrel container /fig.1 - pos.5/ into the ring relief /fig.1 -

pos.6/ end-to-end, thus you depress the arrestment element, and turn

to position 1 or 2. The mandrel container shall thus be in place. Suction

shall initiate in position 2. It is possible to fix up relative positon of the

mandrel container /fig.1-pos.5/ and the ring /fig.1-pos.6/ so that the

outcoming compressed air comes out in a suitable direction (e.g. away

from the operator of the tool)

2. Removing the mandrel container:

Turn the mandrel container end-to-end to position o and pull it out

fig.1/1A of the ring relief.

The suction shall thus switch off

The tool is equipped with a multifunctional mandrel container /fig.1 -

pos.5/ which has the following three positions (see fig.1/1A):

• Position 0 - mandrel container removed

• Position 1 - mandrel container mounted, suction is switched off

• Position 2 - mandrel container mounted, suction is switched on

1. with the mandrel container removed in position 0:

Suction switches off by turning and

removing the mandrel container /fig.1 - pos.5/. Insert BR into the riveting tool through the

nose-piece hole. Depress the trigger to move the jaws offward the BR head. The movement

ends when reaching max. stroke, correct BR with respect for material gauge shall tear off the

shank (riveting) for one stroke of the tool. Releasing the trigger shall return the jaws to initial

position and released torn-off shank can be removed from the nose-piece by tilting the tool.

/fig.1 - pos.1/

2. with the mandrel container mounted in position 1:

Mounting and turning the mandrel

container /fig.1 - pos.5/ to position 1 shall arrest it. Insert BR into the riveting tool through

the nose-piece hole. Depress the trigger to move the jaws offward the BR head. The

movement ends when reaching max. stroke, correct BR with respect for material gauge shall

tear off the shank (riveting) for one stroke of the tool. Releasing the trigger shall return the

jaws to initial position and the released torn-off shank can be transported into the mandrel

container by tilting the tool /fig.l - pos.5/.

3. with the mandrel container mounted in position 2:

Suction switches on by turning the

mandrel container /fig.1 - pos.5/ to position 2. In this position the suction holds BR in the

nose-piece /fig.1 - pos. 1/ which enables riveting in any position without danger of BR falling

out of the nose-piece of the tool. Depressing the trigger shall perform riveting. Releasing the

trigger shall transport the shank into the mandrel container. If the mandrel container is full

with shank to appx. 70%, it is necessary to remove and empty it in a specified manner (e.g.

to a prepared container). Overfill of the mandrel container may result in failure of the riveting

tool.

The tool can be operated in the two following manners:

The tool is equipped with revolving air supply /fig. 1 - pos.4/ which enables manipulation with air

supply before as well as during tool operation, air hose does not obstruct riveting in any position.

The tool is equipped with a trigger /fig.1 - pos.3/. Released trigger enables pushing a rivet into the

tool (the tool is ready for riveting), depressing the trigger shall fix the rivet.

FIGURE.1/1A

FIGURE.1/1B