Operating and maintenance instructions

Installing the motor

Version 1.0

Page 17 of 56

4 Installing the motor

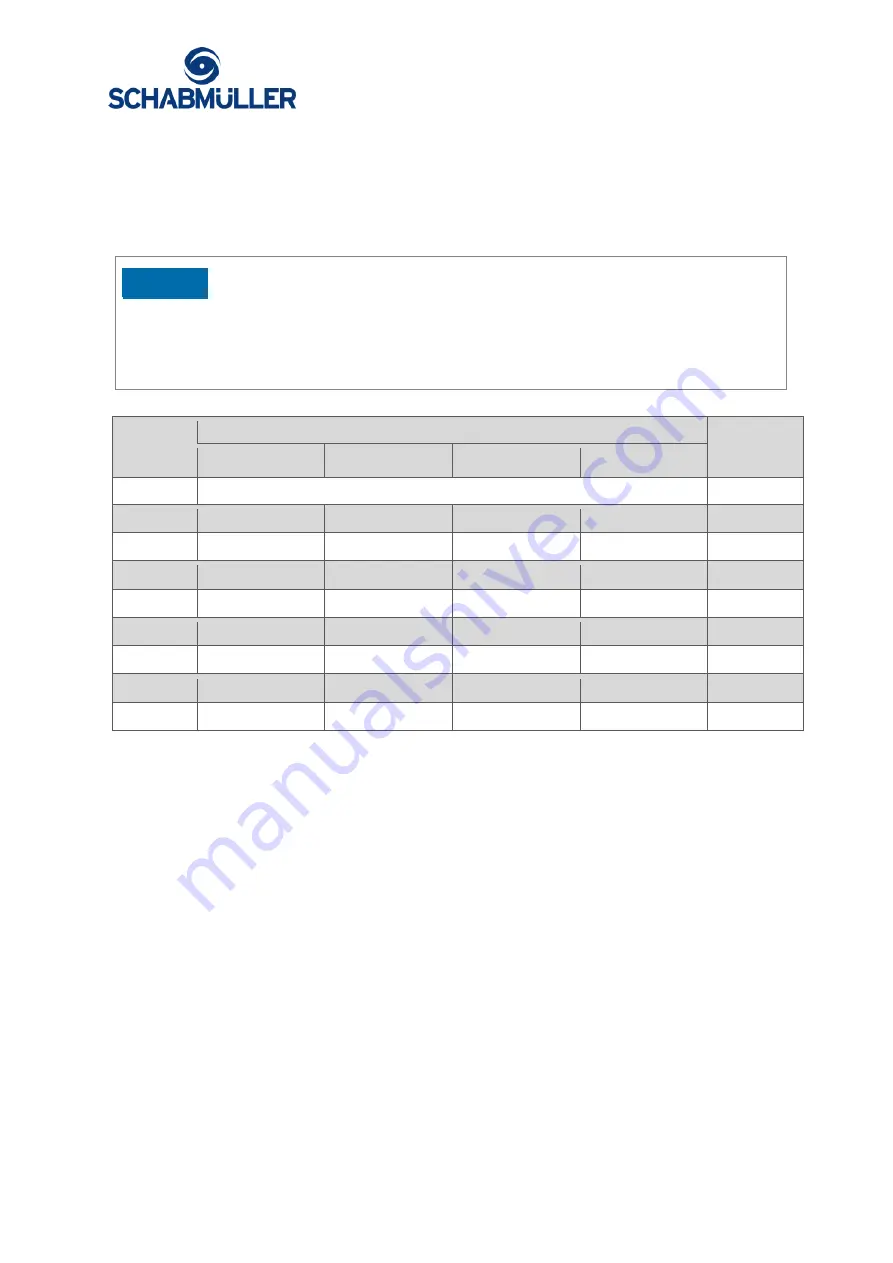

4.1 Tightening torques for fastening elements

Danger of property damage

For attachments, use the tightening torques specified by the manufacturer

If no tightening torques are specified by the manufacturer, refer to the drawing

or the table below for tightening torques

The tightening torques indicated on the drawing have priority

Thread

Production class according to DIN 267

Width

across

flats

4.8

8.8

10.9

12.9

Tightening torques [Nm]

M 3

0.6

1.4

1.9

2.2

5.5

M 4

1.3-1.5

3-3.6

4.3-5.3

5.1-6.1

7

M 5

2.6-3.1

6-7.1

8.5-10

10.2-12

8

M 6

4.5-5.2

10.3-12

14.7-18

17.6-21

10

M 8

10.8-12.5

25.5-30

35.3-44

42.2-52

13

M 10

21.6-25.8

50-60

70.6-87

85.3-100

15

M 12

38.2-45

87.3-105

122-151

147-177

18

M 16

90-100

200-220

290-320

345-380

24

These tightening torques are standard values for metric standard threads according to

DIN 13 and head support dimensions according to DIN 912; 931; 934; 6912; 7994 and

79xx. They result in a 90% utilisation of the bolt yield strength. A coefficient of friction

of 0.14 to 0.20 was assumed (new screw, without post-treatment, unlubricated).

NOTICE