Fire damper BKA-EN

Additional operating instructions according to ATEX 2014/34/EU

Models and dimensions

Construction subject to change

No return possible

Version: 2020-07-10 | Page 8

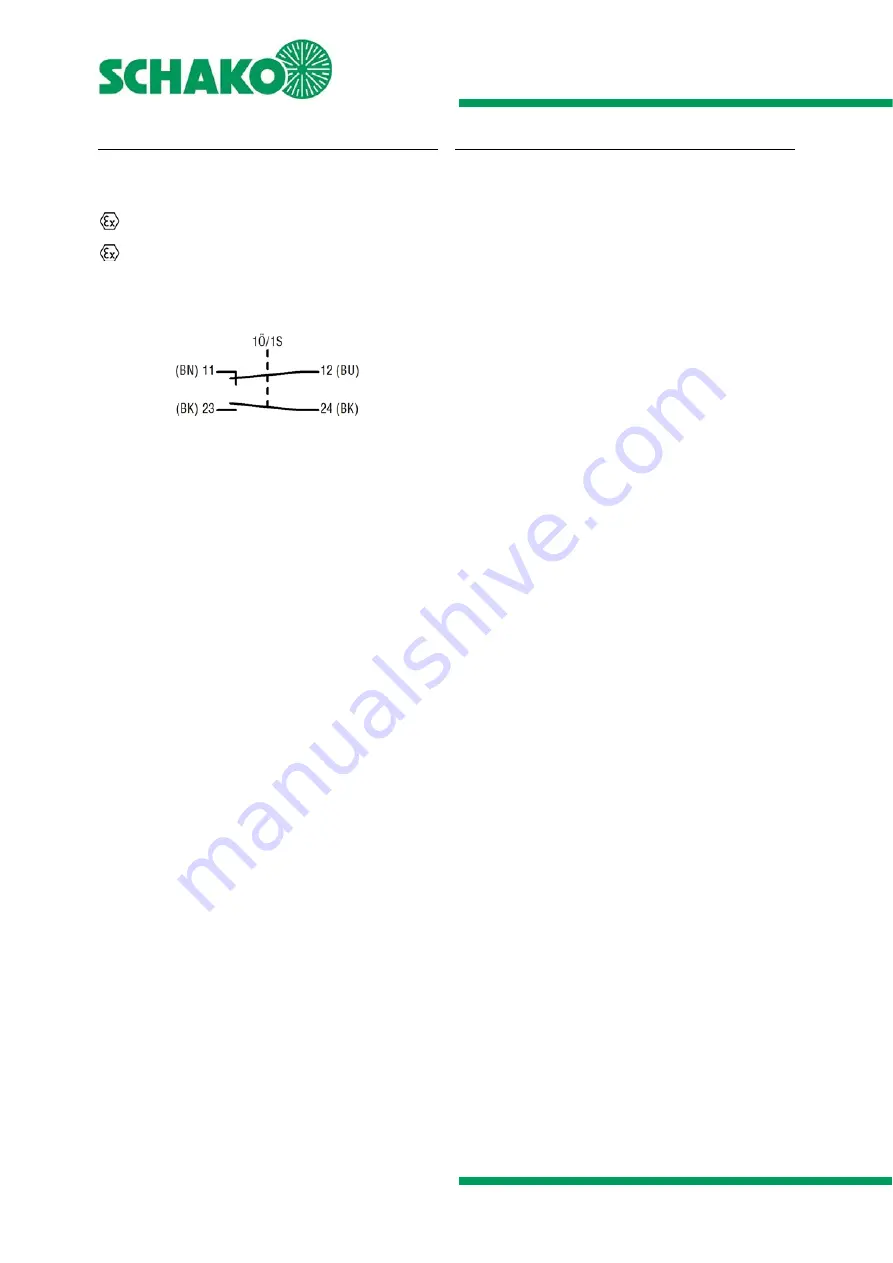

Limit switch type ES-Ex

Limit switch for application in areas subject to explosion haz-

ards

II 2G Ex d IIC T6/T5 Gb,

II 2D Ex tb IIIC T 80°C/ 95°C Db

IP65; 250V / 6A AC15; 230V / 0.25A DC13; -20°C ≤ Ta ≤ +65°C

Figure 4: Circuit diagram limit switch type ES-Ex

Damper positions that can be displayed:

EXZ (type ES-Ex-Z: "CLOSED")

EXA (type ES-Ex-A: "OPEN")

EX2 (type ES-Ex-2: "OPEN" and "CLOSED")

General information

During mounting or installation, there is a risk of injuries.

To avoid any possible injuries, personal protective equip-

ment (PPE) must be worn.

Fire dampers must be installed such that external forces

do not impair their permanent functioning.

Ventilation ducts must not exert significant forces on

walls, supports or ceilings and thus also on fire dampers

as a result of thermal expansion (in case of fire).

Appropriate compensation measures, such as the ar-

rangement of flexible spigots (SCHAKO type FS) or a suit-

able duct routing (duct angles and distortions), must be

taken as required. National regulations must be observed

and implemented

Prior to installing the fire damper, the possible connec-

tions of the ventilation ducts must be checked. Extension

parts (on site or as accessories SCHAKO type VT) might be

necessary, e.g. for large wall and ceiling thicknesses.

When connecting duct components, a fastening type

must be selected that causes no damage to the fire

damper or its accessories.

During mounting it may be required to provide reinforce-

ments for the housing or the like.

The requirement of statically load-bearing lintels may

have to be taken into consideration.

If a fire damper is not filled with mortar on all four sides,

installation and mounting aids on site must be removed.

Improper transport/handling may result in damage/func-

tional impairment. In addition to that, the film of the

transport packaging must be removed and the delivery in-

spected for completeness.

In storage, fire dampers must be protected from dust,

dirt, moisture and the effects of temperature (e.g. direct

sunlight, heat-emitting light source, etc.). They must not

be exposed to direct effects of the weather and must not

be stored below -20 °C or above 50 °C.

The fire damper must be protected from dirt and damage.

After installation is complete, any dirt must be removed

immediately.

Enough space must be provided for installation, mortar

lining, etc.

Carry out a functional check of the fire damper before and

after mounting and ensure ready access.

Electrical installations or work on electrical components

may only be carried out by skilled electricians. The supply

voltage must be switched off when performing this work

and secured against being switched on again.

We would like to point out that only suitable cleaning ma-

terials may be used for cleaning fire dampers in stainless

steel design!