Fire-resistant damper model BKA-Ü

Technical documentation

Installation in lightweight partition walls with metal posts

Construction subject to change

No return possible

Version: 2021-07-01 | Page 16

Dry installation of the damper

The dry installation must be carried out during the assem-

bly of the wall.

The minimum distance of BKA-Ü from one another must be

at least 200 mm.

The minimum distance to adjacent components must be

(due to the design) at least 90 mm from the wall and at least

80 mm from the ceiling. The actual minimum distance may

slightly differ from the distances mentioned therein and

must be executed and adapted as a function of the wall con-

nection type.

Further information to be considered: see page 7 Minimum

distances or projecting ends.

Figure 16: Metal stud frame with required replacement parts

for dry installation

Sectional view

of LPW

Detail W

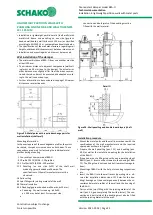

Figure 17: Dry installation in lightweight partition wall

Installation procedure

Mount the metal posts and the wall in accordance with the

specifications of the wall manufacturer and the required ex-

change parts as shown on Figure 14.

Insert BKA-Ü (pos. 1) into the wall recess (operating side -

observe the installation dimension of 210 mm). Average out

the circumferential annular gap evenly between the wall

and BKA-Ü. Mounting of BKA-Ü with the help of mounting

suspensions etc.

Insert mineral wool (pos. 11.3) (non-flammable according to

EN 13501-

1, packing density 80 kg/m³, melting point ≥

1000 °C) into the circumferential gap 40 mm in width be-

tween the housing of BKA-Ü and the circumferential metal

profiles (pos. 10).

Mount the wall panellings on both sides (pos. 12) and the

doublings on the non-operating side (pos. 49.1). The con-

nection and butt joints must be filled with the jointing ma-

terial of the wall (pos. 43; max. gap width 5 mm, perform

jointing operation as part of assembly).

1 Fire-resistant damper model BKA-Ü

9 Profile CW 50/50/06 (with wall thickness = 100 mm, for

larger wall thicknesses, the profiles must be adapted

accordingly)

10 Profile UW 50/40/06 (with wall thickness = 100 mm, for

larger wall thicknesses, the profiles must be adapted

accordingly)

11.1 Mineral wool (according to the wall manufacturer's

specifications)

11.3 Mineral wool, (non-flammable according to EN13501-1,

apparent density approx. 80 kg/m³, melting point

≥

1000

°C, thickness 40 mm)

12 Panelling of the metal post wall made of gypsum-bonded

wall boards

16 Solid ceiling

43 Joint filling with jointing material of the wall

48 Thermal insulation

49.1 Doubling (plaster boards GKF, 2 x d=12.5 mm)

o

First doubling, fastening: Dry-wall screws e.g. TN

3.5x55, a ≤ 250 mm, but at least 2 screws per side; con-

nection and butt joints of the doublings must be filled

with the wall material.

o

Second doubling, fastening: Dry-wall screws e.g. TN

4.5x70, a ≤ 250 mm

, but at least 2 screws per side; con-

nection and butt joints of the doublings must be filled

with the wall material.