Fire damper BKP-EN

Technical documentation

Add-on parts

Construction subject to change.

No return possible!

Version: 2020-09-01 | Page 32

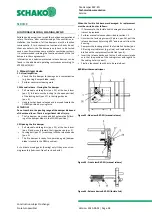

Security grille type ASG

Figure 39: Security grille type ASG

Wire or punch grille with a mesh size of

≤

20 mm

Intended use:

to be fitted for one-sided connection

Minimum distance a

min

= 50 mm from open damper

blade must be taken into account, if necessary, use

extension piece type VT .

Mounting frame type ER-P1

Figure 40: BKP-EN with installation frame type ER-P1 (loose)

Installation frame type ER-P1 made of silicate

boards, incl. fixing lugs, a circumferential intumes-

cent seal being located in the centre of the installa-

tion frame type ER-P1.

Intended use:

For installation of the BKP-EN in lightweight parti-

tion walls with metal posts and panelling on one or

both sides as classified according to EN 13501-2 or

comparable national standards.

The mounting frame type ER-P1 can be delivered

loose as mounting kit or mounted ex works at an ex-

tra charge. If the mounting frame type ER-P1 was

already mounted ex works to the BKP-EN, the instal-

lation can take place immediately.

If the mounting frame type ER-P1 was ordered or delivered

loose as mounting kit, it must be mounted to the BKP-EN

(Figure 40) following the instructions shown below. Moreo-

ver, on the non-operating side, fastening materials (e.g.

screws, press-in nuts, etc.) must be provided and attached for

mounting duct components prior to installation of the mount-

ing frame type ER-P1. Alternatively, extension pieces (on site

or as accessories, e.g. SCHAKO type VT) can be mounted.

To avoid damage to components when mounting the mount-

ing frame type ER-P1, the fire damper must be placed on a

suitable surface (e.g. cardboard, pallet, etc.). All holes re-

quired for screw mounting have been predrilled on the

mounting frame type ER-P1 ex works, so that no further holes

must be drilled. The mounting frame type ER-P1 may not be

screw-connected directly to the housing of the fire damper.

The individual parts of the mounting frame type ER-P1 are po-

sitioned circumferentially at 200 mm (measured from flange

BS).

Mounting procedure

Place the fire damper on the flange of the operator

side (BS).

Place first B part (pos. 17.1) against the housing of

the BKP-EN.

Place first H part (pos. 17.2) likewise against the

BKP-EN and screw it to the first B part (pos. 17.1) in

the overlap area using the delivered drywall screws

(pos. 17.5).

Place second B part (pos. 17.3) against the BKP-EN

and screw it to the first H part (pos. 17.2).

Finally, place second H part (pos. 17.4) against the

BKP-EN (pos. 1) and screw it to both the first (pos.

17.1) and the second B parts (pos. 17.3).

Position indicator type MSZ

Figure 41: Position indicator type MSZ

Steel cable - galvanised - (pos. 21) with clamping

nipple (pos. 22) and position indicator (pos. 23)

made of plastic material; the steel cable and the po-

sition indicator must be mounted perpendicularly.

Intended use:

Mechanical position indicator for false ceilings (pos.

24). Usable for each mechanically operated BKP-EN

with hand lever.

21 Steel cable -galvanised- 23 Position indicator

22 Clamping nipple

24 False ceiling