Fire damper BKP-EN

Technical documentation

Service

Construction subject to change.

No return possible!

Version: 2020-09-01 | Page 38

SERVICE

FUNCTIONAL CHECKING, CLEANING, REPAIR

Polluted and damp air can impair the continuous operational

safety. Therefore, after commissioning of the ventilation in-

stallation, the function of all fire dampers must be checked

semiannually. If two consecutive functional checks do not

show any defects, the fire dampers only have to be tested

once a year. If maintenance are made for ventilation systems,

it is recommended including the functional checks of the fire

dampers in these agreements.

Information on explosion-protected release devices can be

found in the additional operating instructions according to

ATEX 2014/34/EU.

1. Manual trigger device

1.1. Visual inspection

Check the fire damper for damage and contamination

(e.g. housing, damper blade, seals).

Perform necessary cleaning work

1.2 Manual release - Closing the fire damper

Pull manual unlocking disc (pos. 25) at the hand lever

(pos. 3), this removes the locking (in the open position)

of the locking bolt (pos. 27) in the trigger device

(pos. 5).

Hand lever has been released and is moved toward the

CLOSED position by spring force.

ATTENTION!

Do not reach into the pivoting range of the damper blade and

of the manual lever. There is a significant risk of injury.

The fire damper must close and lock automatically (lock-

ing of the damper blade in the CLOSED position).

1.3 Opening the fire damper

Pull manual unlocking disc (pos. 25) at the hand lever

(pos. 3) and move it toward the trigger device (pos. 5)

Locking bolt (pos. 27) must snap into the release device

(pos. 5).

The fire damper is ready for operation again (damper

blade is locked in the OPEN position).

S = Lubricate moving parts (bearing) only if they are not run-

ning smoothly (lubricant: free of resin and acid).

When the fusible link becomes damaged, its replacement

must be carried out as follows.

If, for example, the fusible link is damaged or corroded, it

is must be replaced.

Perform manual release as described in section 1.2.

Unscrew the fastening screws (2 pieces, pos.26), pull the

release device out by turning it 90° and remove it from the

housing.

Compress the locating pins of the fusible link holder (pos.

28) using a suitable tool (e.g. pliers) and replace the fusi-

ble link with a replacement fusible link (pos. 6).

Insert the release device and fasten it with screws (make

sure that the position of the coding screw with regard to

the coding hole is correct).

Finally a functional check has to be carried out.

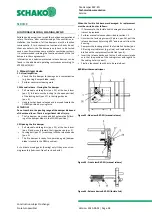

BKP-EN with manual trigger

Figure 42: Side view BKP-EN (manual release)

Figure 43: Front view BKP-EN (manual release)

Figure 44: Release device BKP-EN (fusible link)