Fire damper BKP-EN

Technical documentation

Service

Construction subject to change.

No return possible!

Version: 2020-09-01 | Page 39

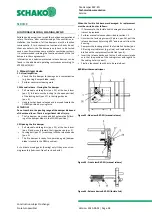

2. Trigger device with electric spring return actuator

2.1. Visual inspection

Check the fire damper for damage and contamination.

Perform necessary cleaning work.

2.2 Thermoelectric release – Closing the fire damper

Press switch (pos. 30) on the thermoelectric release de-

vice (pos. 31), thus removing the electric power from

the spring return actuator (pos. 29) (alternatively: inter-

rupt on-site power supply).

Fire damper must close automatically, locking is per-

formed by blocking the spring return actuator.

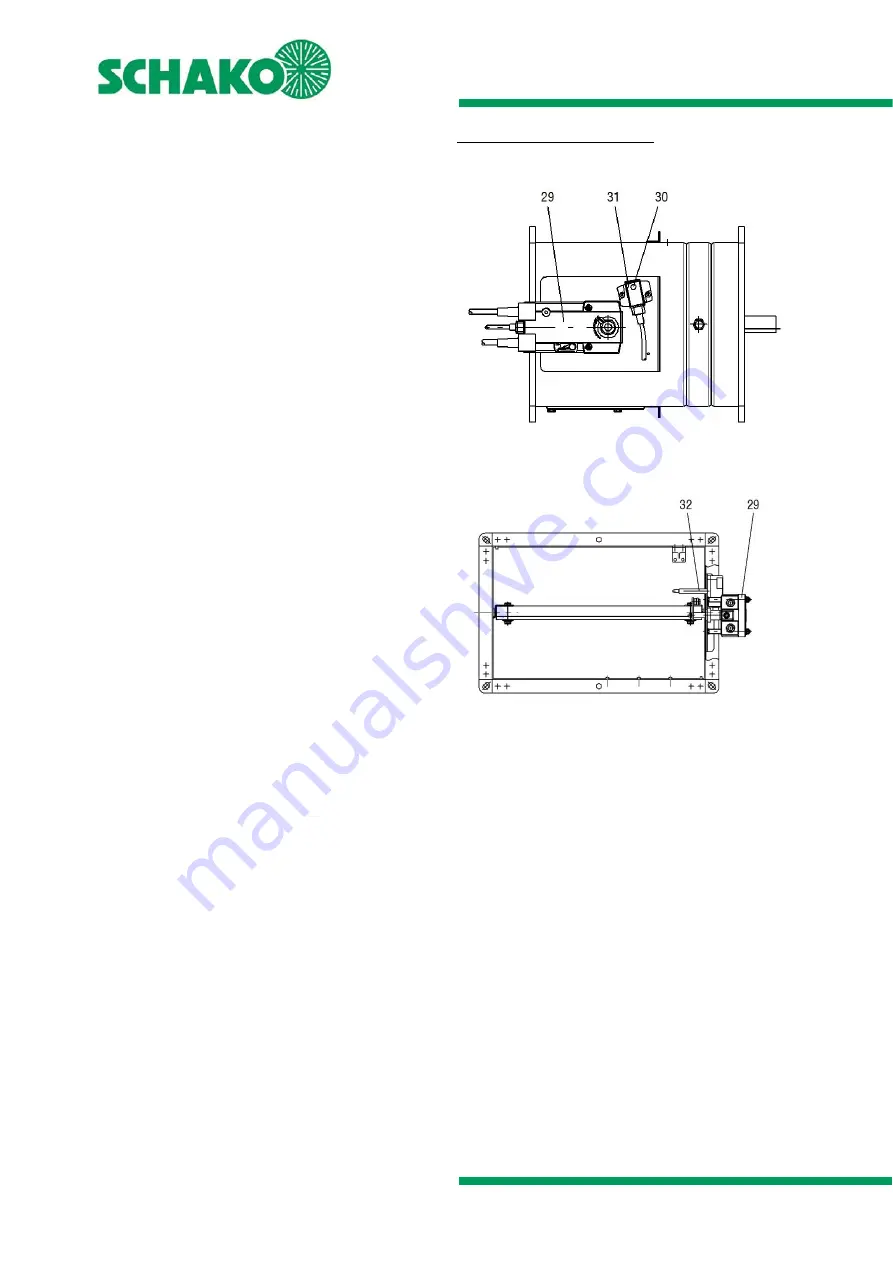

When the fusible link becomes damaged, its replacement

must be carried out as follows.

Replacement takes place by unscrewing both screws of

the thermoelectric release device/temperature moni-

toring unit (pos. 31).

Remove the thermoelectric release device from the ac-

tuator unit. Pull the internal duct temperature

fuse/duct tip (pos. 32) off the thermoelectric release

device/temperature monitoring unit and replace it

with a new internal duct temperature fuse (ZBAT72 or

ZBAT95) or duct tip (ASK79.4 or ASK79.5), depending

on the type of the actuator.

Reinsert the thermo-electric release device/tempera-

ture monitoring unit into actuator unit and screw it

down.

Carry out a functional check.

BKP-EN with spring return actuator

Figure 45: Side view BKP-EN (spring return actuator)

Figure 46: Front view BKP-EN (spring return actuator)