Fire damper BSK-RPR-EU

Technical

documentation

Installation

information

Construction subject to change

No return possible

Version: 2015-02-01 | Document: 09/48 | Page 7

INSTALLATION INFORMATION

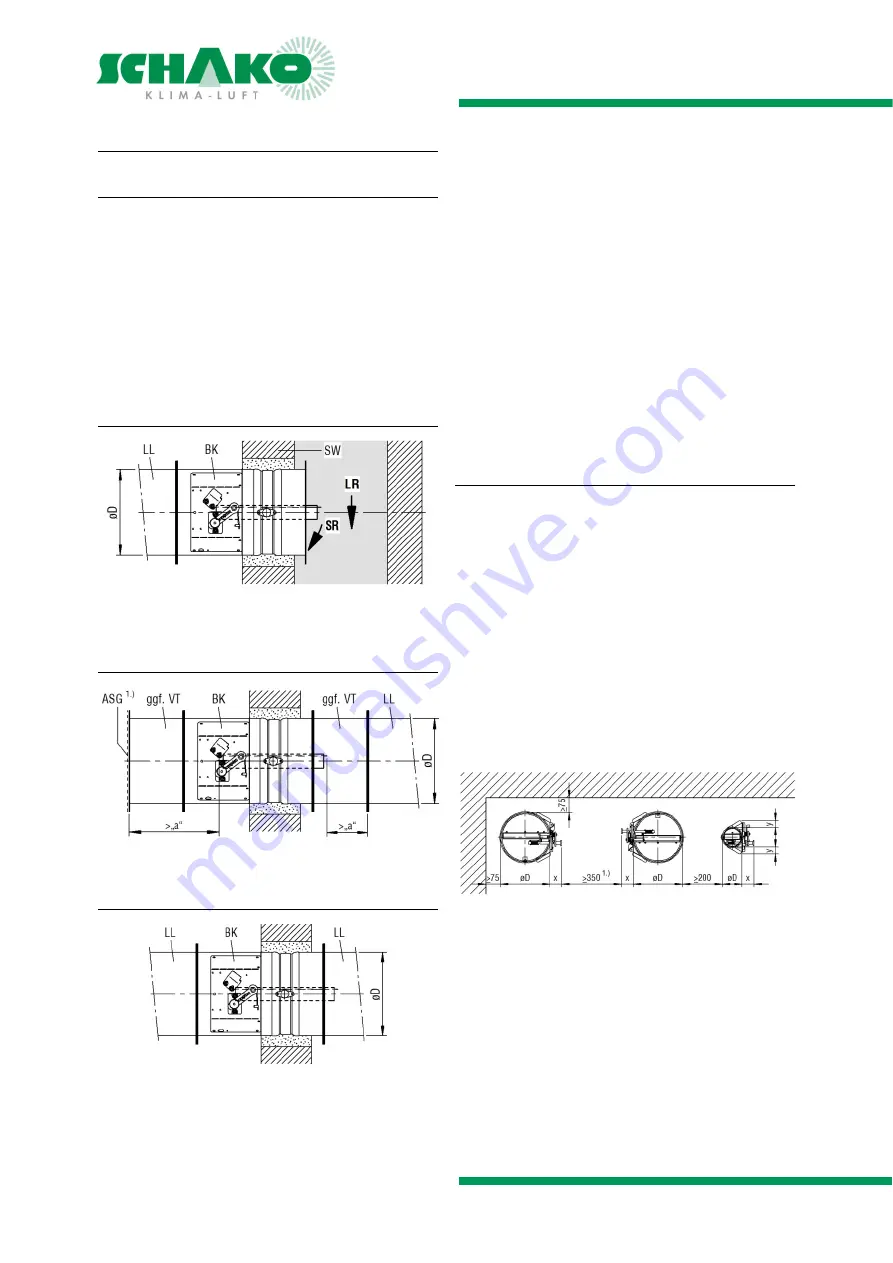

Connection of ventilation ducts

The fire dampers must be connected to the ventilation ducts

of the ventilation system either on one or both sides. When

connected on one side, finishing protective gratings made of

non-flammable building materials (EN13501-1) must be pro-

vided on the opposite side. The fire dampers can be connec-

ted to non-flammable or to flammable ventilation ducts.

The local regulations or national standards regarding ventila-

tion systems (in Germany, e.g. LüAR) apply. Especially in case

of fire, no inadmissible forces may have impact on the fire

damper and the space-enclosing components and impair

their fire resistance period.

In solid shaft walls

Figure 9: Connection example of a ventilation duct arran-

ged on one side in solid shaft walls

With ventilation duct arranged on one side and finishing

protective grating

Figure 10: Connection example of a ventilation duct arran-

ged on one side and finishing protective grating

On both sides with flammable ventilation duct

Figure 11: Connection example on both sides with ventila-

tion ducts

BK

Fire damper BSK-RPR-EU

ASG

Finishing protective grating type ASG

1.)

VT

Extension piece type VT

LL

Ventilation duct

SW Shaft

wall

SR Closing

direction

LR

Air flow direction

ggf. if

necessary

1.)

made of non-flammable building materials (EN 13501-1)

"a" = 50 mm: Minimum distance between the front edge of

the open damper blade and the finishing protective grating

(ASG-RF/-RS).

MINIMUM DISTANCES OR PROJECTING ENDS

The dimensions given must be considered an installa-

tion recommendation for the BSK-RPR-EU and may dif-

fer, depending on the local situation. To guarantee fire

protection, the fire damper must be installed in ac-

cordance with the technical documentation, installati-

on, mounting and operating instructions.

There are no inspection openings on the BSK-RPR-EU,

which is why inspection openings in the connected

ventilation ducts must be provided in the immediate

proximity. Inspection openings must be freely acces-

sible, which must be ensured especially if minimum 2

fire dampers are installed next to each other or below

each other in the direct vicinity of load-carrying, ad-

jacent components.

Figure 12: Minimum distances between walls, ceilings and

BSK-RPR-EU

1.)

Minimum distances recommended by SCHAKO with regard

to later maintenance

The dimension x is:

- Manual trigger approx. 75 mm

- Spring return actuator approx. 85 mm

The dimension y is:

- Manual trigger and spring return actuator max. 50 mm