Fire damper BSK-RPR-EU

Technical documentation

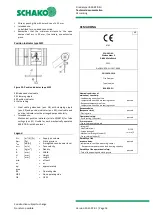

Installation in solid walls

Construction subject to change

No return possible

Version: 2021-07-01 | Page 8

Wet installation (mortar lining)

The fire damper is installed by means of mortar lining. It

must be completely filled with mortar of class M 10 to M

15 according to EN 998-2 or fire protection mortar of cor-

responding grades or with concrete or plaster mortar

suitable for the wall or ceiling type.

If the fire damper is installed during the assembly of the

wall, the annular gap dimensions can be smaller than

specified.

The mortar bed depth must be designed according to the

minimum wall thickness and may not be less than this

thickness.

The mortar lining must be executed such that it is perma-

nent. The information given by the mortar manufacturer

must be observed.

INSTALLATION IN SOLID WALLS

Installation in solid walls (shaft walls, shafts, ducts and fire

walls) made of, for example, concrete; masonry according

to EN 1996 or DIN 1053; solid plaster wall boards according

to EN 12859; apparent density ≥ 450 kg/m³ and wall thick-

ness W

≥

150 mm.

Installation positions

Mortar lining entire wall thickness

Mortar lining in minimum wall thickness

Figure 8: Wet installation in solid walls

Wet installation of a fire damper, complete mor-

tar lining

The minimum distance between the fire dampers must be

at least 50 mm.

The minimum distance from adjacent components

(wall/ceiling) is at least 75 mm.

Figure 9: Annular gap dimensions for complete mortar lining

in solid walls (round or rectangular recess)

Wet installation at a reduced distance

Installation of no more than 2 BSK-RPR-EU in an installation

opening in solid walls at a reduced distance next to or below

each other. All annular gaps have to be filled with mortar.

The distance between the fire dampers must be min. 50

mm.

The distance to adjacent components (wall/solid ceiling)

is at least 75 mm.

Figure 10: Installation in solid walls at a reduced distance

(round or rectangular recess)