Fire damper BSK-RPR-EU

Technical documentation

Installation information

Construction subject to change

No return possible

Version: 2021-07-01 | Page 9

INSTALLATION INFORMATION

Connection of ventilation ducts

The fire dampers must be connected to the ventilation system

by means of ventilation ducts either on one or on both sides.

When connected on one side, finishing protective gratings

made of non-flammable building materials (EN13501-1) must

be provided on the opposite side. The fire dampers can be con-

nected to non-flammable as well as flammable ventilation

ducts. Ventilation ducts must be suspended separately.

The local regulations or national standards on ventilation sys-

tems (in Germany e.g. LüAR) apply. It is important that ventila-

tion ducts do not exert significant forces on walls, supports or

ceilings and thus also on fire dampers as a result of thermal

expansion (in case of fire). Appropriate compensation

measures, such as the arrangement of flexible spigots or a suit-

able duct routing (duct angles and distortions), must be taken

as required. National regulations must be observed and ad-

hered to.

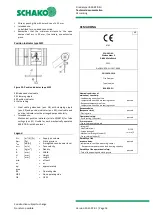

In solid shaft walls

Figure 11: Connection example of a ventilation duct in solid

shaft walls

With ventilation duct arranged on one side and security

grille

Figure 12: Connection example of a ventilation duct ar-

ranged on one side and security grille

On both sides with ventilation ducts

Figure 13: Connection example of ventilation ducts on both sides

BK

Fire damper BSK-RPR-EU

ASG

Security grille, type ASG-RF/ASG-RS

VT

Extension piece type VT-RF

LL

Ventilation duct

SW

Shaft wall

SR

Closing direction

LR

Air flow direction

BS

Operating side

NBS

Non-operating side

1.)

made of non-combustible building materials (EN

13501-1)

„a“

=50mm

Minimum distance between the front

edge of the open damper blade and the

finishing protective grating (ASG-RF/RS)