Installation, Mounting and Maintenance DISA-W

Z11/27 - 10

Construction subject to change.

No return possible!

20.10.2015

Version:

Checking the primary volumetric flow

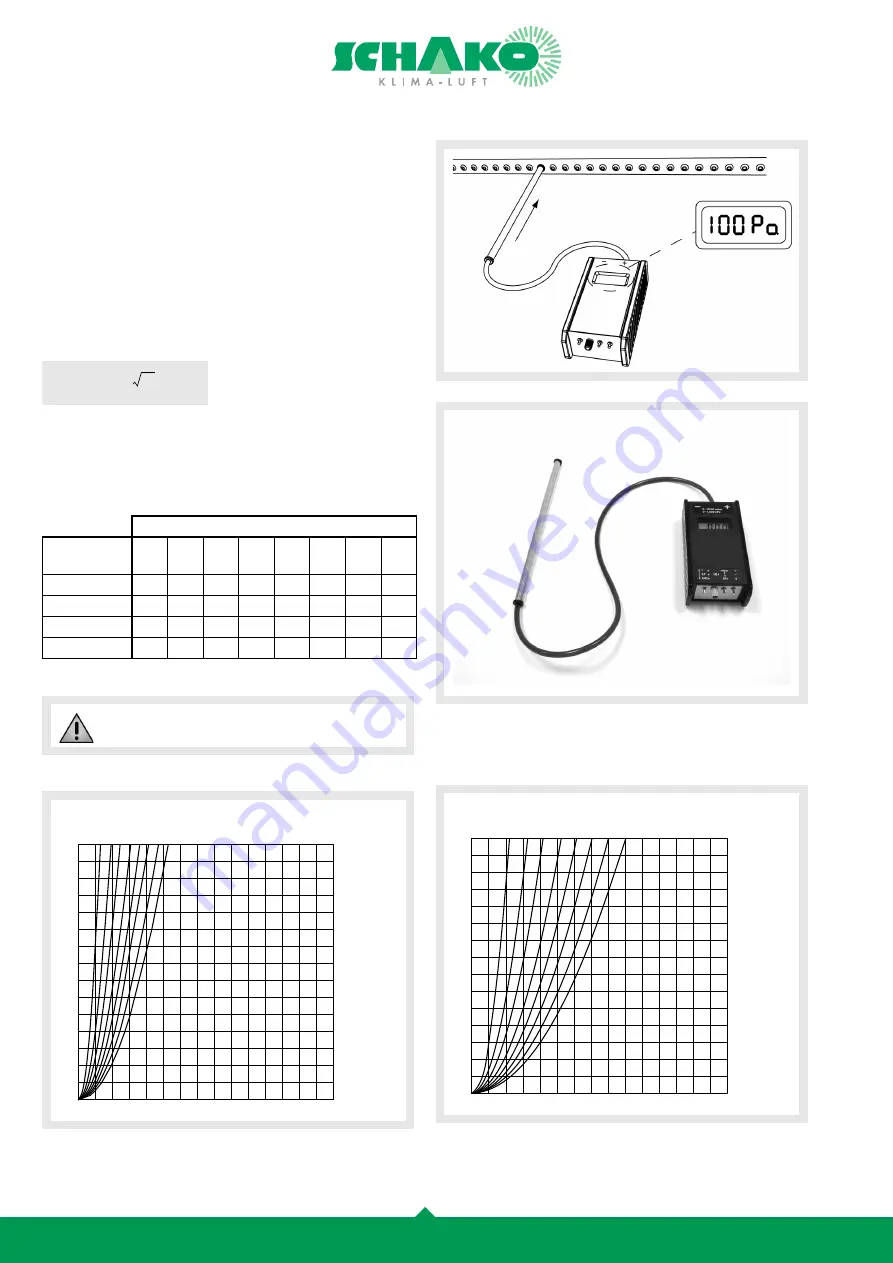

The supplied primary volumetric flow can be simply checked by

checking the static pressure with a Pa meter and the measuring

tube available from us as accessory.

To this end, one end of the measuring tube fitted with a rubber

cap is pressed against the air outlet of one of the nozzles at the

primary air plenum box (see drawing) and the other end is con-

nected to the hose connection of a Pa meter.

The values read on the meter and the following formula can be

used to to determine the volumetric flow:

V [l/s] = Primary air flow

Ps [Pa] = Static pressure

The K value is taken from the following table:

Air density:

ρ

= 1.2 kg/m

3

Nozzle configuration A

Nozzle configuration B

NL

(mm)

Nozzle config-

uration

900 1200 1500 1800 2100 2400 2700 3000

?A

0,42 0,62 0,79 0,99 1,16 1,32 1,51 1,69

B

0,71 1,06 1,35 1,69 1,98 2,27 2,59 2,90

C

1,32 1,96 2,50 3,14 3,68 4,21 4,80 5,39

D

1,97 2,92 3,72 4,67 5,48 6,28 7,15 8,03

V

K Ps

=

The Pa meter is not included in the delivery.

Vzu (m

3

/h)

0 20 40 60 80 100

200

300

0

20

40

60

80

100

200

300

'

P (Pa.)

900-A 1200-A 1500-A 1800-A 2100-A 2400-A 2700-A 3000-A

900-B

1200-B

1500-B

1800-B

2100-B

2400-B

2700-B

3000-B

Vzu (m

3

/h)

0 20 40 60 80 100

200

300

0

20

40

60

80

100

200

300

'

P (Pa.)