Installation, Mounting and Maintenance DISA-W

Z11/27 - 6

Construction subject to change.

No return possible!

20.10.2015

Version:

Installation

The wall induction diffuser type DISA-W is suitable for vertical

installation in a wall or ceiling panelling. The devices must not

be installed in places with extreme moisture (e.g. laundries or

swimming pools), aggressive media, with high dust formation,

outdoors or in places subject to explosion hazards.

For correct installation, the following instructions must be fol-

lowed:

Mounting

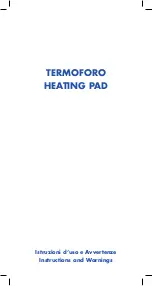

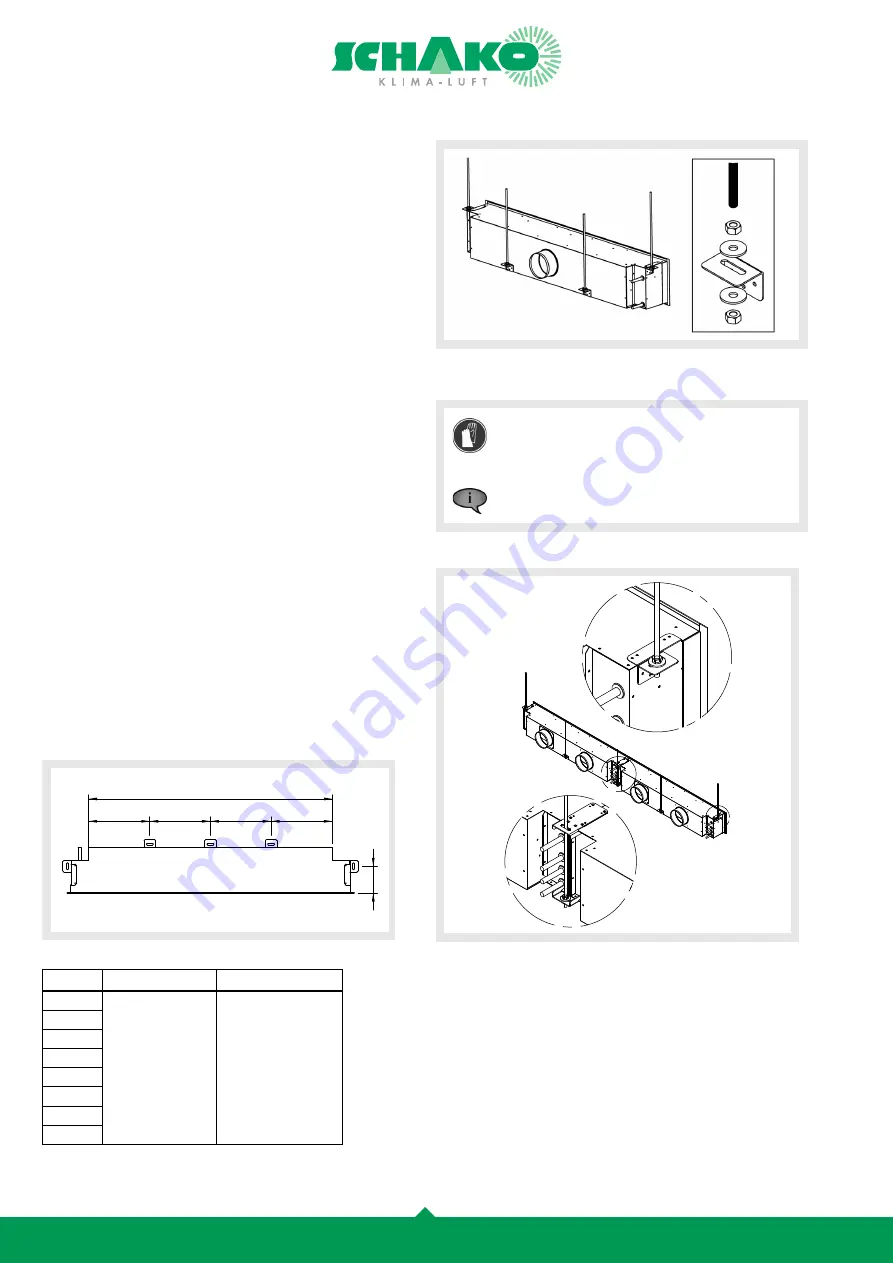

The DISA-W series was developed for vertical installation in a

wall. The device is suspended from a load-bearing ceiling using

fastening material approved by the building supervisory author-

ities, for example M6 threaded bars. Fastening takes place on

the fixing lugs provided ex works.

During mounting the end of the register pipes must be sealed to

protect them from dust and dirt.

Band design

When ordering -BV (band connection), the band connection

parts are delivered as accessories. The connection elements are

fastened to the device on one side using the delivered screws

and can be fastened to the load-bearing ceiling using threaded

bars provided on site or other fastening material approved by

the building supervisory authorities.

- Make sure that places that are intended as openings for air

admission and air discharge are free of pipes, electric ca-

bles, crossbeams, stands, etc.

- Install the unit at a site that has good air quality.

- Make sure that wall and ceiling correspond to the weight of

the device and also allow correct mounting of the fastening

elements in the ceiling.

- The installation site must have sufficient space and the nec-

essary resources for carrying out mounting and mainte-

nance activities of all device components. Make sure that

the valves are easily accessible.

- The hydraulic pipes should be attached above the device.

- If the hydraulic pipework is lower than the input of the de-

vice, a ventilation opening must be provided on site.

NL (mm) 1 connecting piece 2 connecting pieces

900

a,c

a,b

1200

1500

1800

2100

2400

2700

3000

a

c

b

c

a

NL-155

1/4

1/4

115

1/4

1/4

For the installation of the device, use adequate

tools, devices and materials and observe the safety

regulations and other current regulations.

SCHAKO cannot be held liable for damage result-

ing from faulty installation or the use of unsuitable

fastening devices.

A

A

B

B