Installation, Mounting and Maintenance DISA-W

Z11/27 - 7

Construction subject to change.

No return possible!

20.10.2015

Version:

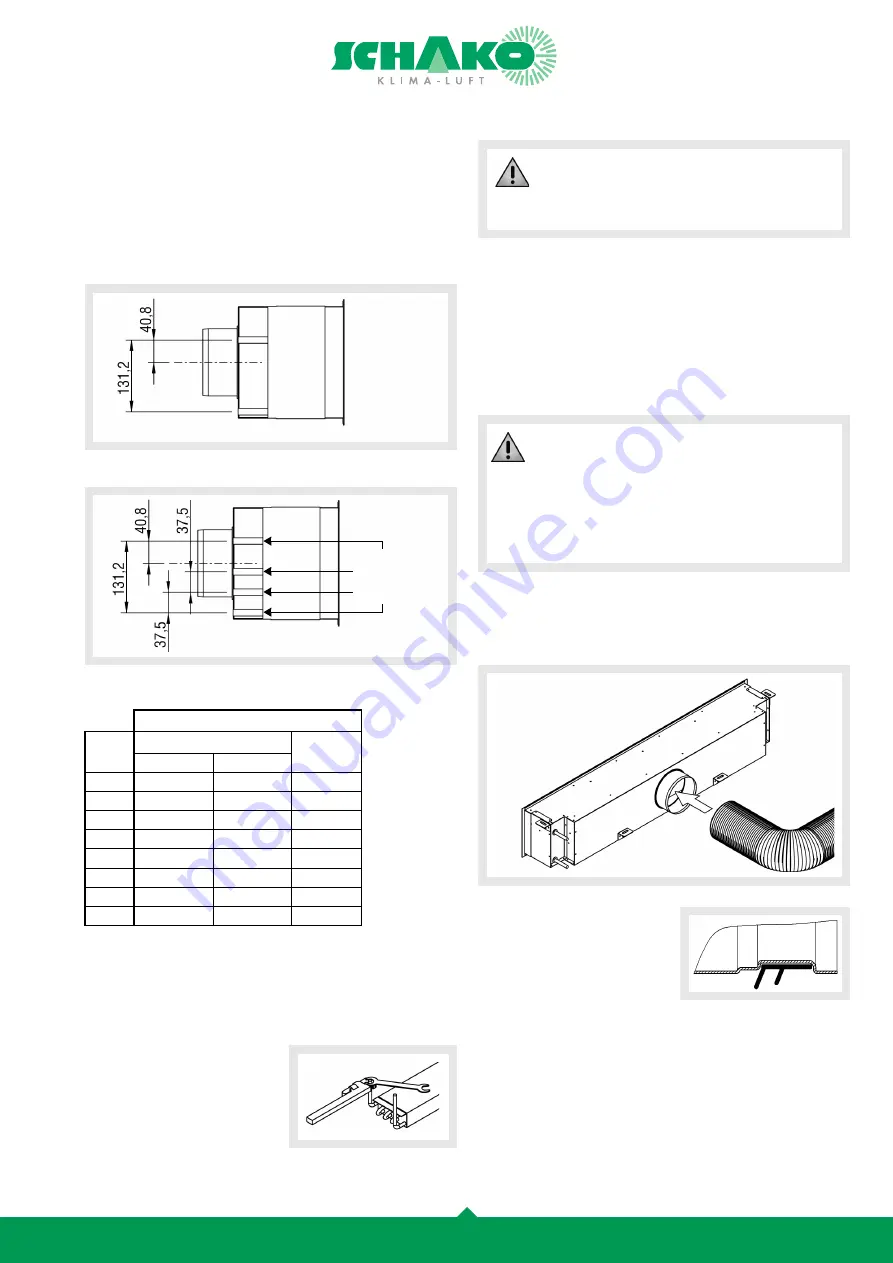

Hydraulic connections

Upon customer request, the hydraulic connection to the regis-

ters can be established either on the left-hand (-

WS1

) or right-

hand side (-

WS2

) of the unit.

As standard the cooling circuit pipes are attached on the outside

and the heating circuits at the centre of the register.

Hydraulic connections DISA-W-H (2-pipe)

Hydraulic connections DISA-W-HT (4-pipe)

Amount of water of the registers:

The connection of the hydraulic connections can be done by sol-

dering, pressing (in connection with supporting sleeves) or by

means of flexible hoses resistant to oxygen diffusion and push-

fit systems. The use of flexible hoses is subject to the manufac-

turer's specification.

When making the hydraulic con-

nections, you have to use suitable

tools

to avoid excessive tightening or

twisting of the register connec-

tions.

When charging the register, make sure by means of on-site ven-

tilation devices that no air remains in the hydraulic circuit.

If the unit is to be installed at a location having temperatures be-

low zero degrees, glycol must be admixed to the coolant in a

suitable ratio, to ensure that the freezing point of this liquid al-

ways stays below the minimum temperature of the operating

site. Please note that the use of an antifreeze necessarily results

in a loss in performance of the register.

Connecting the air ducts

The air ducts are attached by using pipe clamps, fixing lugs or

the like.

Optionally, a rubber lip seal can

be installed on the connection

pipe, to ensure tightness be-

tween the device and the pipes.

Water capacity

(litres)

NL

DISA-W-HT

DISA-W-H

Heating

Cooling

900

0,2

0,6

0,8

1200

0,3

0,8

1

1500

0,3

1

1,3

1800

0,4

1,2

1,6

2100

0,5

1,4

1,8

2400

0,5

1,6

2,1

2700

0,6

1,8

2,4

3000

0,7

2

2,7

Heating Coolin

g

In order to achieve a uniform cooling capacity, the

wall induction diffusers type DISA-W should be

connected to the cold water distribution system in

parallel.

The wall induction diffusers type DISA-W are induc-

tion devices for "dry cooling".

To avoid condensation, the cold water supply tem-

perature must be selected such that it does not fall

below the dew point, which may make it necessary

to install protective devices (condensate monitors).