Smoke extraction blade damper ERK-MB

TECHNICAL DOCUMENTATION

Installation details |

Construction subject to change

No return possible

Stand: 2019-10-08 | Page 14

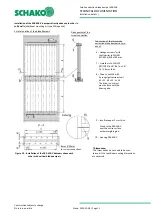

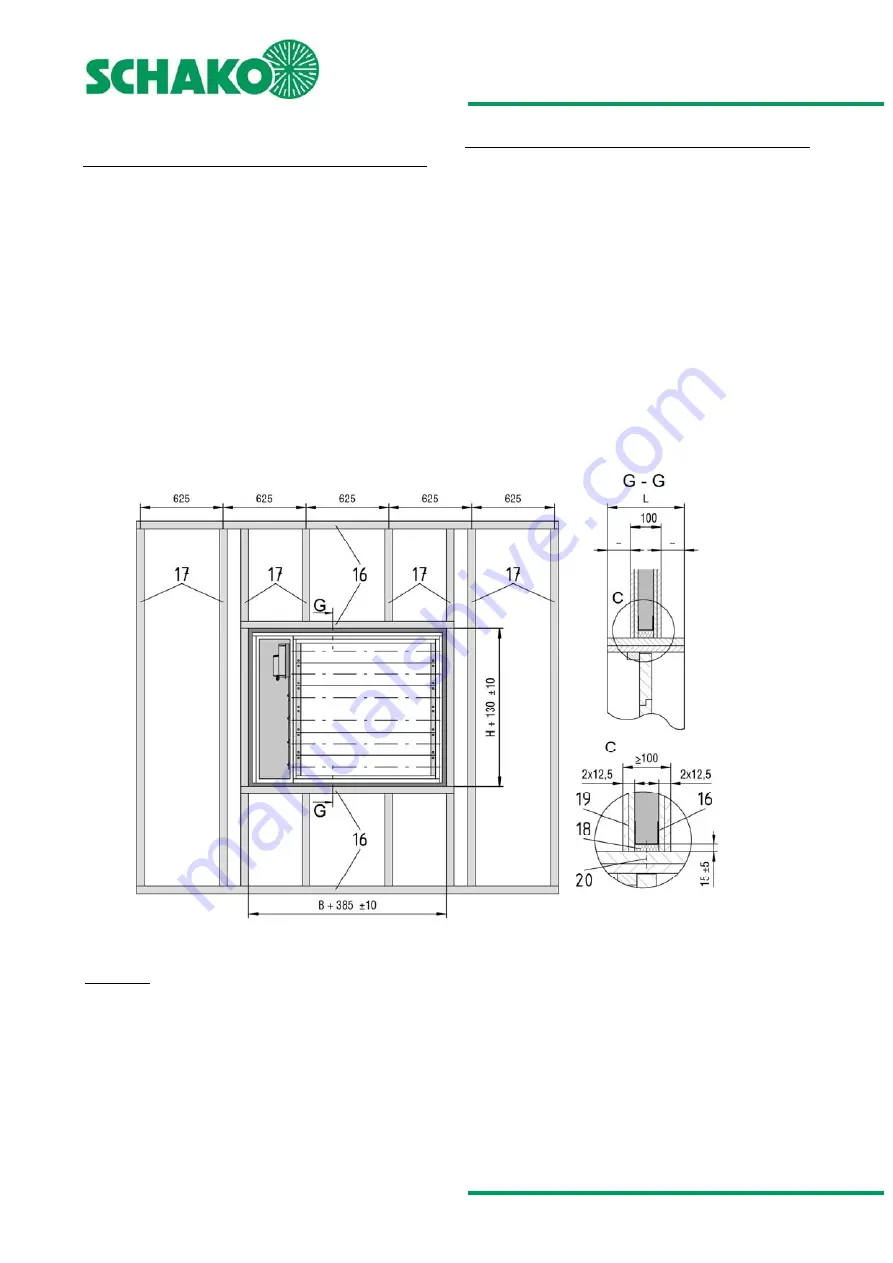

Installation in dry building walls with metal posts and

panelling on both sides

Installation of the ERK-MB-V in dry building walls with metal

posts and panelling on both sides (gypsum-bonded wall boards;

wall thickness ≥ 100 mm) according to classification to EN

13501-2 or comparable national standards.

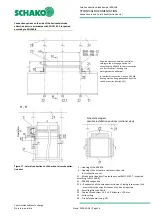

No additional suspensions or attachments of the ERK-MB-V are

allowed, and installation and mounting aids must be removed it

they were used.

The ERK-MB-V must be installed during the construction of

the wall and in dry walls.

The distance between the smoke extraction blade dampers

must be at least 200 mm.

The distance to adjacent components (wall/ceiling) is at least

75 mm.

Figure 13 - Metal posts with required

exchange parts and opening dimensions

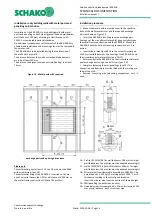

Please note

Circumferential gaps (at least ≥ 10 to ≤ 20 mm) must be filled

with mineral wool (pos. 18).

Circumferential fixing of the ERK-MB-V is carried out by me-

ans of universal screws (pos. 20) at a distance of ≤ 250 mm on

the metal frame construction (UW and CW profiles).

Installation procedure

Mount the metal posts in accordance with the specifica-

tions of the wall manufacturer and the required exchange

parts as shown on Figure 13.

Insert the ERK-MB-V into the prepared exchange part.

Average out the circumferential annular gap evenly between

the metal frame construction and the ERK-MB-V. Mount the

ERK-MB-V with the help of mounting suspensions, etc. if re-

quired.

Insert mineral wool (pos.18) into the circumferential gap

15±5 mm in width between the housing of the ERK-MB-V and

the circumferential metal profiles (pos. 16+17).

Permanently fix the ERK-MB-V on the circumferential metal

post exchange part using universal screws (pos. 20).

Complete fastening the wall panellings (pos.19). The

connection and butt joints must be filled with the jointing ma-

terial of the wall.

Remove mounting aids (mounting suspensions, etc.) if

used.

16 -- Profile UW 50/40/0.6 (for wall thickness = 100 mm, for larger

wall thicknesses, the profiles must be adapted accordingly)

17 -- Profile CW 50/50/0.6 (for wall thickness = 100 mm, for larger

wall thicknesses, the profiles must be adapted accordingly)

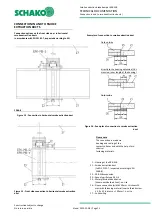

18 – Mineral wool (non-flammable according to EN13501-1, ap

parent density ≥ 100 kg/m³, melting point ≥ 1000 °C, min.

thickness according to the actual gap dimension.

Insert the mineral wool over the entire profile web height.

19 – Wall panelling (on both sides, double)

20 – Universal screw, for example 4.0 x 50 mm, distance a ≤ 250

mm, or min. distance, but 2 screws per side.

Detail