21

2019-05-24 / V1.0

Contactors C137/C163/C164/C165 – Installation and Maintenance Instructions

Installation

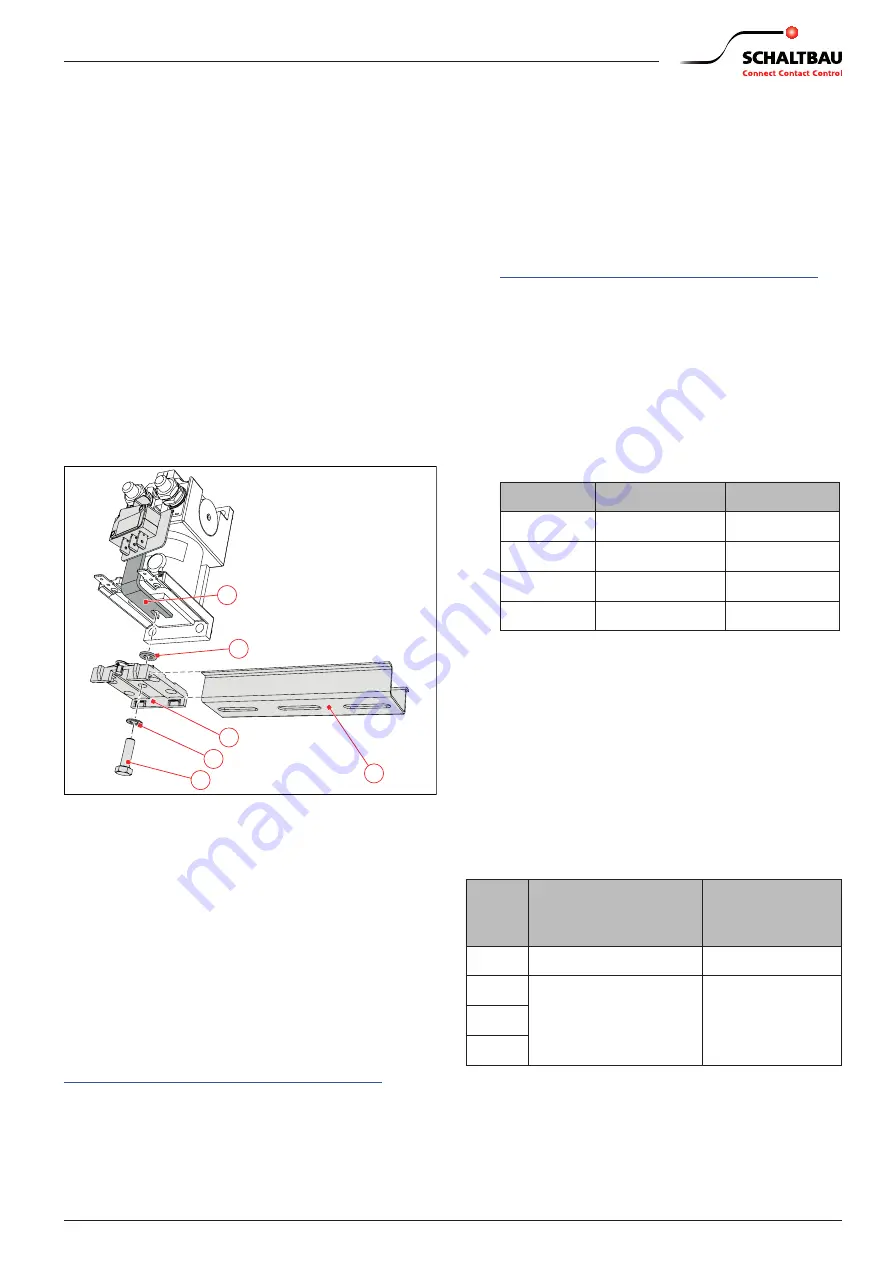

Installation on the bottom side

X

Loosen the hexagon screw (9) at the bottom side

of the contactor.

X

Place the spacer sleeve (10) between the angled

mounting bracket (11) of the auxiliary contact and

the DIN rail adapter (4).

X

Slightly fasten the DIN rail adapter (4) with the

hexagon screw (9) and washer (8).

X

Adjust the angled mounting bracket (11) of the

auxiliary contact.

-

Ensure safe switching of the auxiliary contact!

X

Tighten the hexagon screw (9) with a torque of 2

Nm.

X

Attach the installed contactor with the DIN rail

adapter (4) to the DIN rail (7).

10

7

9

8

4

11

Fig. 21: DIN rail mounting: Installation on the bottom side

(the figure shows C163, the procedure for C137, C164

and C165 is the same)

7.2 Electrical installation

Electrical data and further technical

specifications

For the power consumption of the magnetic drive sys-

tem and electrical data of the auxiliary switches refer

to the respective data sheets and to our catalogue

B60

.

The catalogue is available under:

https://www.schaltbau.com/en/media-library/

Preliminaries

X

The connection of the main current circuit can be

done with wires or busbars.

X

The minimum gauges of the wires/busbars must

be observed. For the required cross sections of

wires/busbars refer to our catalogue

B60

.

The catalogue is available under:

https://www.schaltbau.com/en/media-library/

X

If wires are used, the wire gauges must be selected

in coordination with their insulation class and the

operating conditions.

X

Depending on the contactor type the wires of the

main current circuit must be fitted with appropri-

ate cable lugs (for terminal nuts M6, M8 or M10)

X

The terminal nuts for the main contacts and the

maximum permissible torque for the different

contactor series are determined as follows:

Series

Terminal nuts

Torque

C137

M6

max. 3 Nm

C163

M8

max. 6 Nm

C164

M8

max. 6 Nm

C165

M10

max. 10 Nm

X

In order to secure the terminal nuts against self-

loosening, appropriate screw locking elements

have to be provided. Schaltbau recommends

Schnorr-Washers (or similar) to secure the nuts.

The terminal nuts against must be tightened with

the determined torque (refer to the table above).

X

The terminals of the coil and the auxiliary contact

are designed as flat tabs. Therefore the control

wires must be fitted with appropriate flat recep-

tacles for tabs. Depending on the series, the table

shows the type of flat receptacles.

Series

Auxiliary contact

terminals:

flat receptacles for tabs

Coil terminals:

flat receptacles for

tabs

C137

A 2.8 x 0.5 mm

A 6.3 x 0.8 mm

C163

A 6.3 x 0.8 mm

A 6.3 x 0.8 mm

C164

C165

X

The maximum permissible cross section of the

auxiliary contact control cables is 1 mm

2

/ AWG 18

stranded wire.