User Manual, Power contactors, series CT1115/08 and CT1130/08

Rev. 2.2

Page 14/26

Operating position

Make sure that you have received the correct contactors for the application.

CT1000 contactors can be mounted horizontally or vertically.

Horizontal mounting position

Vertical mounting position 1

Vertical mounting position 2

In most cases, the contactors are mounted on mounting plates or mounting

frames. They must be solid enough to carry the weight of the contactors un-

der the shock and vibration conditions of the railway environment.

The contactors (Lower Module) are fixed with 4 or more mounting screws,

depending on the number of poles. The screws (and if applicable the nuts)

must be steel grade 8.8. Schaltbau strongly recommends Schnorr-Washers

(or similar) to secure the screws. The screws must be tightened with the rat-

ed torque permissible for the screws and the nuts.

Mechanical requirements

Device dimensions

Refer to the dimensioned drawings of the contactors.

Installation dimensions

Refer to the dimensioned drawings of the contactors.

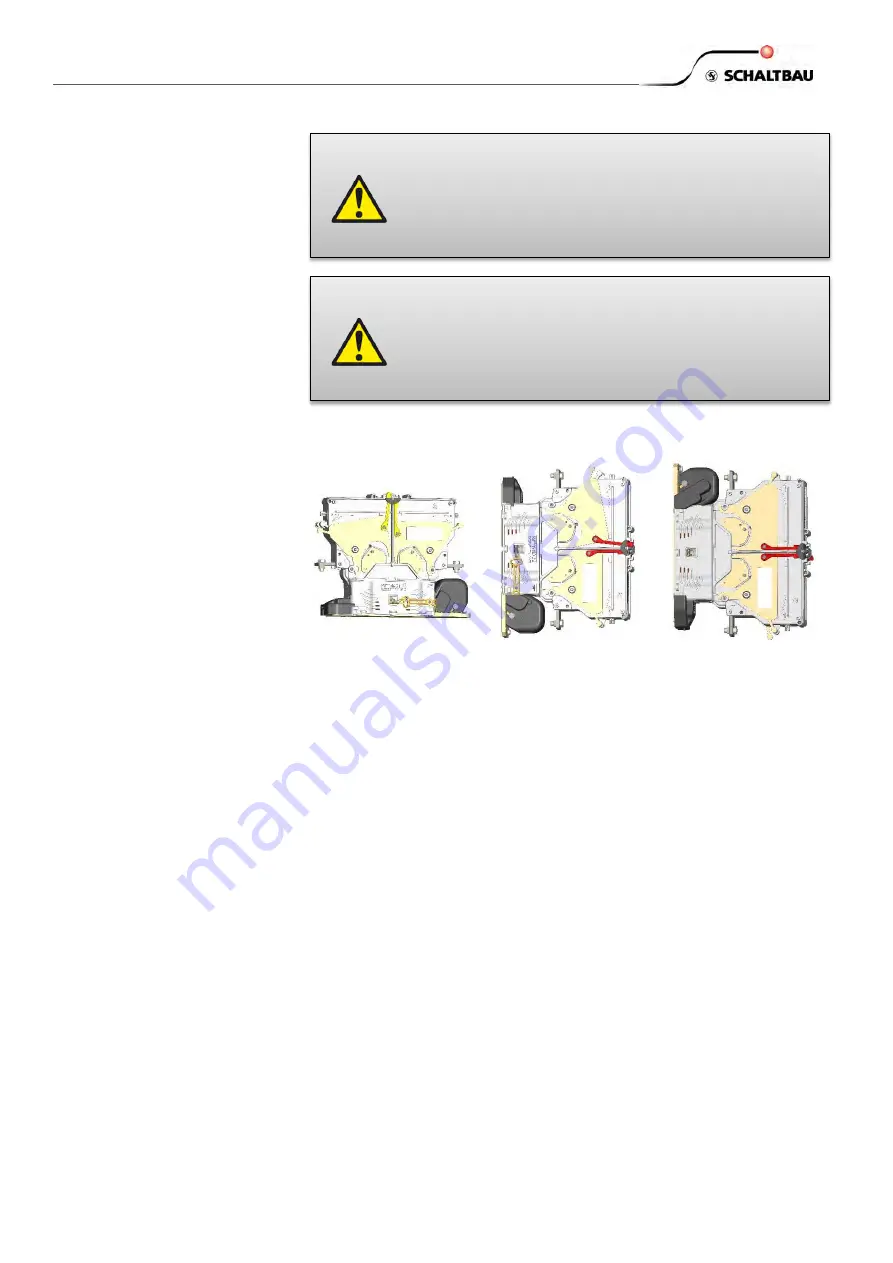

CT1000 contactors for horizontal mounting must only be

mounted horizontally (Lock bars are yellow, position is also

shown on the labels); they can be mounted in any position in

reference to the direction of movement of the vehicle. Make

sure that both Upper and Lower Module are for horizontal

mounting.

CT1000 contactors for vertical mounting must only be mount-

ed vertically (Lock bars are red, position is also shown on the

labels). Make sure that both Upper and Lower Module are for

vertical mounting.