User Manual, Power contactors, series CT1115/08 and CT1130/08

Rev. 2.2

Page 19/26

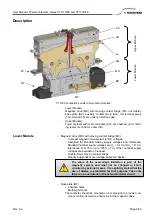

Maintenance

CT1000 contactors are maintenance-free within the rated mechanical

life time. The electrical life time depends on the number of switchings

under heavy load conditions and may vary for different applications.

In normal use, this corresponds to a decade-long operating period.

Recommended regular

service intervals

Checking activity designation

Checking interval

Optical inspection from outside

1x annually

Inspection of the main contacts

1x to 2x annually depending on ap-

plication

Inspection of the auxiliary contacts

Every 2 years

Unscheduled service in-

tervals

Inspection activities

High voltage supply cables or current bars

Check of the high voltage supply cables/bars and the tightening torques of

the fastening screws.

Earthing

Check of the supply cables and the tightening torques of the fastening

screw.

Cleaning

In case of excessive dirt the surface of the contactors should be cleaned.

Inspection of the main contacts

Disconnect the main terminals and remove the Upper Module. Inspect the

main contacts (both fixed and movable contacts).

It requires some experience to evaluate the state of the contacts. Even after

only a few switchings under load the contacts look used and “polluted” for

the inexperienced eye. Contacts need only to be replaced if the wear of the

contact tips is more than 70%.

Replace the Upper Module and secure it. Reconnect the main terminals.

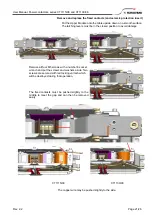

Inspection of the auxiliary contacts

Disconnect the main terminals and remove the Upper Module.

Remove the protection cover. The auxiliary switches are visible for a simple

optical inspection from the outside (housings are clean and do not show

signs of short-circuits etc.). Under normal working conditions (no short cir-

cuit switching) the life time of the auxiliary switches exceeds those of the

contactors.

Replace the protection cap and the Upper Module and secure it. Reconnect

the main terminals.

Auxiliary switches S870 are not visible when you have removed the cap.

You will need to remove the 2 screws and lift the assembly for inspection.

Extraordinary services need only be carried out if there has

been a significant and extraordinary recorded number of

switchings under fault conditions.

If the contactors are being used in particularly dirty environ-

ments, the checking intervals for the optical inspection should

be shortened, because dirt can impair the insulation clear-

ances and there is therefore the possibility of a shorter ser-

vice life or an operational fault.