www.scheppach.com

service@scheppach.com

+(49)-08223-4002-99

+(49)-08223-4002-58

18 І 32

Warning!

This electric tool generates an electromag-

netic field du ring operation which may impair active or

passive medical implants under certain circumstances.

ln order to reduce the risk of severe or Iethal injury, we

recommend that persons with medical implants consult

their doctor and the manufacturer of the medical implant

before using the power tool.

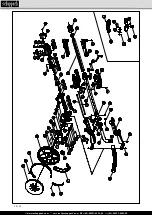

Tool description and scope of delivery

Tool description (Fig.1)

The tool description refers to the illustration at the begin-

ning of this instruction manual.

1. Handle surface

2. Main handle

3. On/off switch

4. Adapter with connecting nut

5 Powercord

6. Adjustment wheel for speed pre-selection

7. Ventilation opening

8. Flexible grinding head

9. Grinding plate

10. Brush edge

11. Extraction hose

12. Hoseadapter

13. Abrasive sheet

14. LED-Light

Scope of delivery (Fig.1)

1 drywall sander

1 extraction hose (1 1)

2 hose adaptor (1 2)

6 abrasive sheets (1 3) (different grain sizes)

Before start-up

unpacking

1. Open the packaging and carefully takeout the power

tool.

2. Remave the packaging material as weil as the pack-

aging I transport Iacks (if any).

3. Check the scope of delivery for completeness and

check the power tool and the accessory parts for

transport damage.

Note:

Do not start the power tool if you notice that parts

are missing or damaged. Contact the retailer where you

purchased this power tool.

4. Store the packaging until the end of the warranty pe-

riod, if possible. Piease dispose ofthe packaging in

accordance with environmental regulations and take

it to a recycling depot.

WARNING!

Neither power tools nor packaging materials are

toys! Children must not play with plastic bags, foils

and small parts! Danger of swallowing and suffo-

cation!

Installation

- Fold the front and back parttagether (Fig.2). And then

tighten the screw nut. (Fig.3).

- The Iongest length installation Insert the additional han-

dle to the end of the machine. And then turn the screw

nut on the end ofthe machine for tightening. (Fig.4)

c) Keep your body away from the area where the

power tool may move in the event of a kickback.

Kickbacks always move the power tool in opposite

direction to the movement of the grinding disk at the

spot where it blocks.

d) Corners, sharp edges, etc. must be processed

with special care.

Make sure that the insertion tool

does not bounce back from or get trapped on the work

piece. The rotating insertion tool tends to jam in cor-

ners, at sharp edges or when it bounces back. This

may cause the loss of control or a kickback.

e) Do not use chain rings or toothed saw blades.

These insertion tools frequently cause kickbacks or

the loss of control of your power tool.

Additional safety notes regarding grinding with

sandpaper- Special safety notes regarding grinding

with sandpaper

a) Do not use oversized abrasive sheets; always ob-

serve the manufacturer‘s specifications for abra

-

sive sheet dimensions.

Abrasive sheets protruding

the grinding plate may cause injury or result in the

blocking or tearing apart of the abrasive sheet or in

kickbacks.

Additional safety notes

a) Connect a vacuum cleaner to the supplied adapter

before starting your operations.

b) Attention! Keep away grinding dust from open Iire.

Dust may be explosive.

c) Always wear goggles and a dust mask when grinding,

in particular du ring overhead work and when process-

ing critical materials! When grinding certain materi-

als (e .g.lead paint, certain types of wood and metaI)

harmful or noxious dust may be generated. Touching

or breathing in such dust may imply risks for the op-

erator or people in the vicinity.

Notes regarding vibration and noise emissions

Reduce noise emissions and vibrations to a minimum!

1. Only use power tools which are free of defects.

2. Maintain and clean the power tool on a regular basis.

3. Adjust your way of working to the power tool.

4. Do not overload your power tool.

5.Have your power tool inspected, if necessary.

6. Switch off the power tool when it is not in use.

Remaining risks

Even if you use this power tool in compliance with the

regulations, there arestill remaining risks. The follow-

ing risks may occur due to the type and design of the

power tool:

a) Damage caused to your health resulting from hand/arm

vibrations if the power tool is used over a Ionger period

of time or if it is not properly used and maintained.

b) lnjury and damage to property caused by flying off inser

-

tion tools which are unexpectedly expelled from the power

tool due to sudden damage, wear or incorrect insertion.

c) Burns and cuts if the insertion tools are touched di-

rectly after use and/or with your bare hands.