21

• All protective and safety equipment must be rein-

stalled immediately upon completion of any repair or

maintenance work.

REGULAR MAINTENANCE

The regular maintenance decribed above and in the para-

graph below can be carried out by unskilled personnel.

• Do not oil the plunge cut saw, cause cutting must be

carried out in dry conditions; all rotating parts are

self-lubricating.

• During maintenance, wear protective gear if possible

(accident-prevention goggles and gloves).

• Remove cuttings when necessary both from the cutting

area, work surfaces and support bases.

Use of an aspirator or brush is recommended.

ATTENTION:

Do not use compressed air jets!

• Regularly check blade conditions: if difficulties should

arise during cutting, have it sharpened by skilled per-

sonnel or replace it if necessary.

•

ASSISTENCE

When in need of skilled personnel for special main-

tenance, or for repairs, both during and following the

guarantee pe riod, always apply to authorized centres for

assistance or directly to the manufacturer if there is no

authorized centre in your area.

DISPOSAL OF THE MACHINE.

Once its operating activity is finished, the disposal of the

machine must take place through a normal collection and

disposal Center for industrial waste.

Check electrical connection cables regularly for dam-

age. Make sure the cable is disconnected from the mains

when checking.

Electrical connection cables must comply with the regu-

lations applicable in your country.

Single-phase motor

• The mains voltage must coincide with the voltage spec-

ified on the motor’s rating plate.

• Extension cables up to a length of 25 m must have a

cross-section of 1.5 mm

2

, and beyond 25 m at least

2.5 mm

2

.

• The connection to the mains must be protected with a

16 A slow-acting fuse.

Only a qualified electrician is permitted to connect the

machine and complete repairs on its electrical equip-

ment.

In the event of enquiries please specify the following

data:

• Motor manufacturer

• Type of current of the motor

• Data recorded on the machine’s rating plate

• Data recorded on the switch’s rating plate

If a motor has to be returned, it must always be dis-

patched with the complete driving unit and switch.

m

Maintenance

If specialist personnel must be brought in for extraordinary

ser vice or repairs during the warranty period and thereaf-

ter, please contact a service provider recommended by us or

con tact the manufacturer directly.

• Only perform repair, maintenance and cleaning work

as well as the correction of malfunctions with the drive

switched off and the power plug unplugged as a ba-

sic rule.

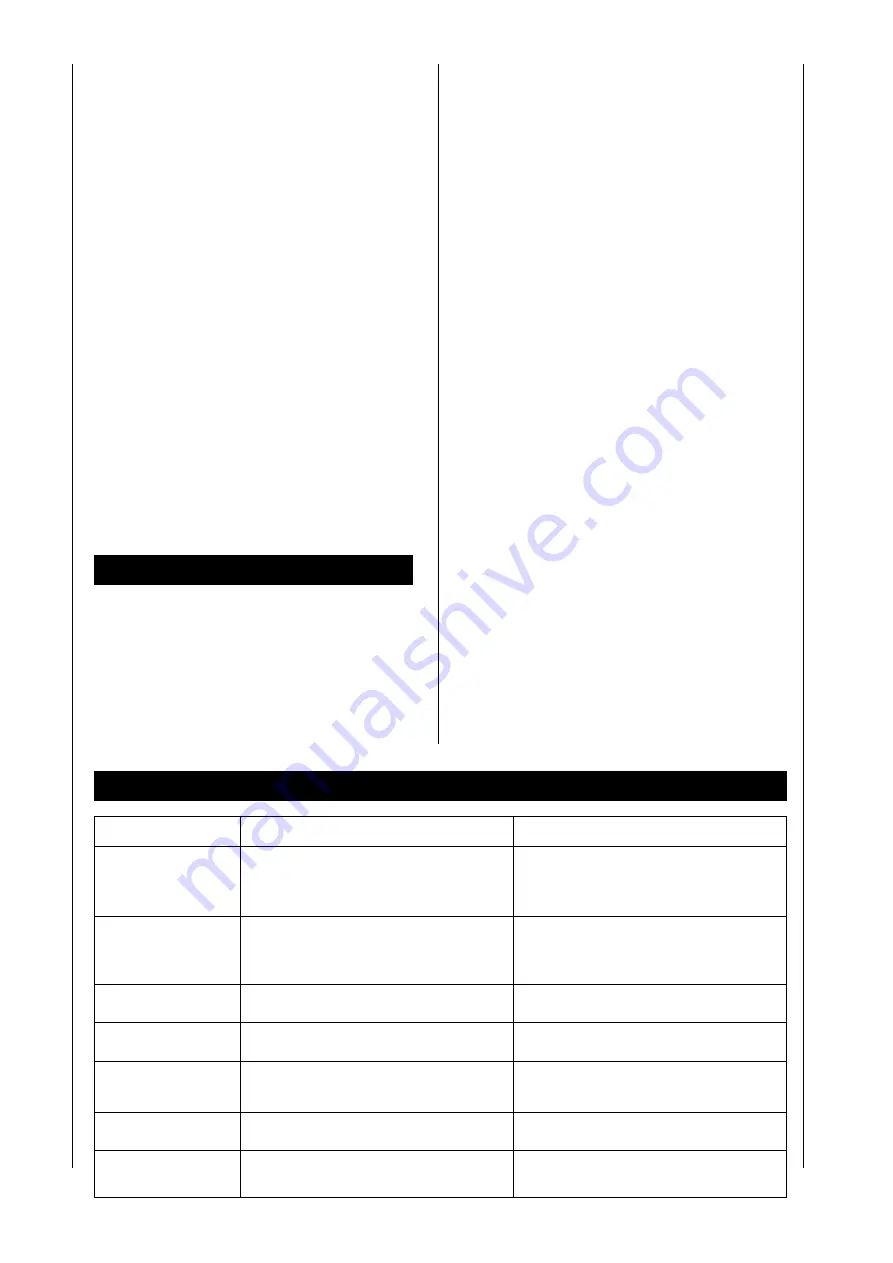

Trouble shooting

Problem

Possible Cause

Help

The motor does not run. Faulty motor, power supply cable or plug.

Burned out fuses.

Have the machine checked by skilled person-

nel. Do not try to repair the machine yourselves

as it may be dangerous. Check the fuses and

replace them if necessary.

The motor starts slowly

and does not reach run-

ning speed.

Low power supply voltage. Damaged windings.

Burned out capacitor.

Ask for the Electricity Board to check the

voltage available. Have the machine motor

checked by skilled personnel. Have the capaci-

tor replaced by skilled personnel.

Excessive motor noise.

Damaged windings. Faulty motor.

Have the motor checked by skilled personnel.

The motor does not

reach full power.

Overloaded circuit due to lighting, utilities or

other motors.

Do not use other utilities or motors on the cir-

cuit to which the plunge cut saw is connected.

Motor overheats easily

Overload of the motor; inadequate cooling of

the motor

Prevent overloading the motor when cutting;

remove dust from the motor to ensure an opti-

mum cooling of the motor

The saw cut is rough or

wavy

The saw blade is dull; the tooth shape is not

suited to the thickness of the material

Re-sharpen the saw blade or use an appropri-

ate saw blade

The work piece rips or

splinters

The cutting pressure is excessive or the saw

blade is not suited to the application

Use the correct saw blade