www.scheppach.com /

service@scheppach.com /

+(49)-08223-4002-99 /

+(49)-08223-4002-58

GB

| 31

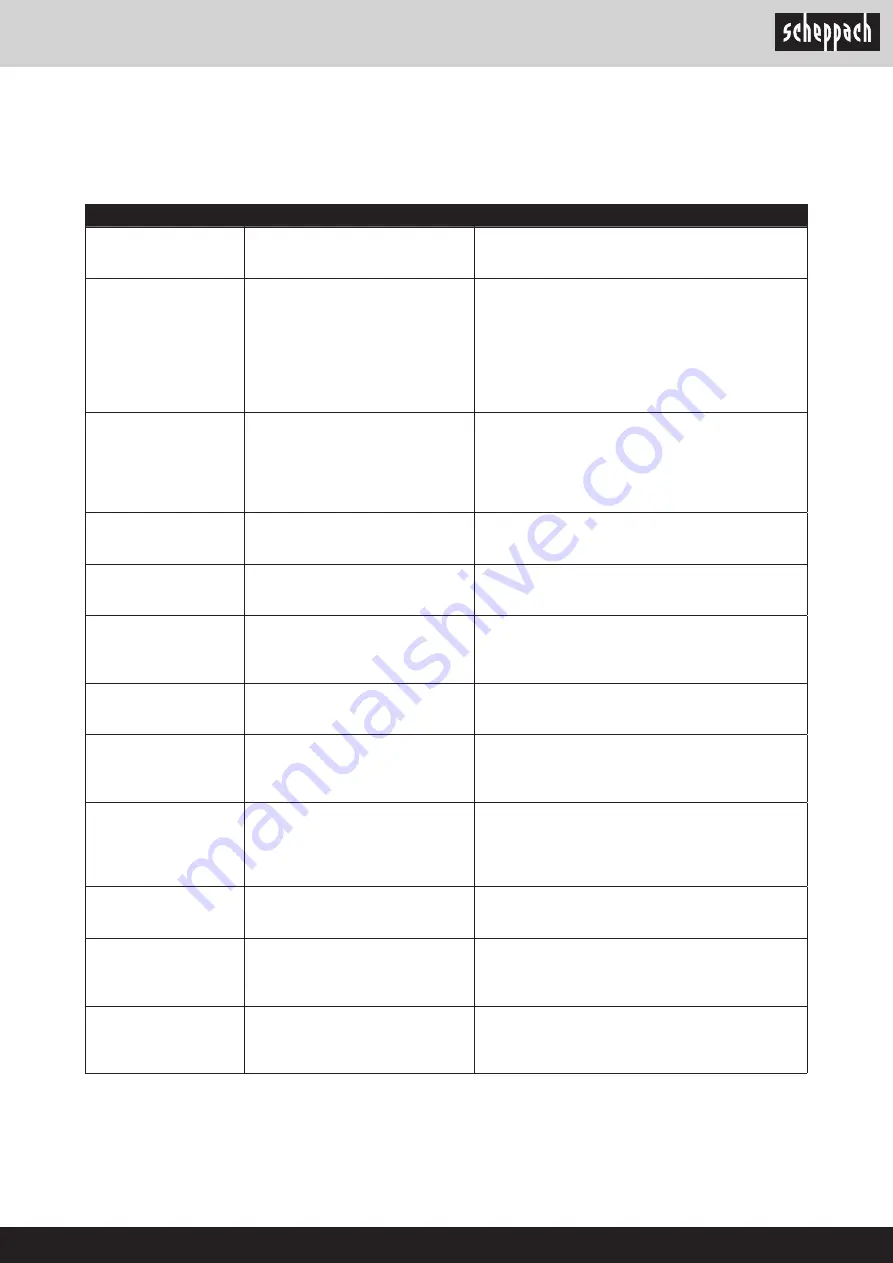

14. Troubleshooting

The table below contains a list of fault symptoms and explains what you can do to remedy the problem if your equipment

fails to work properly. If the problem still persists after working through the list, please contact your nearest service work

-

shop.

Problem

Possible Cause

Remedy

Machine cannot be

switched on.

No power supply.

Carbon brush worn.

Chip extractor not mounted

Check power supply.

Take machine to your service point.

Machine does not work

or stops suddenly

Power cut

Motor or switch defective

Check microswitch

Check fuse, check overload switch on machine.

Have the motor or switch checked by an electrician.

Fit the chip extractor hood so that the microswitch is

pressed.

Check fuses.

Due to the integrated lowvoltage protection, the ma-

chine does not restart automatically. Upon return of

the voltage, the machine must be switched on again.

Machine stops during

planing.

Planing blade blunt/worn

Overload switch has tripped

Check microswitch

Too much chip removal

Too fast feed

Replace or sharpen blade

Switch on the motor again once it has cooled

Fit the chip extractor hood or bench lock so that the

microswitch is pressed.

Reduce chip removal.

Reduce infeed speed.

Workpiece jams during

thicknessing

Cutting depth too great

Reduce cutting depth and machine the workpiece in

several passes

Speed decreases when

planing

Too much chip removal

Too fast feed

Blunt knives.

Reduce chip removal.

Reduce infeed speed.

Replace knives.

Unsatisfactory surface

finish

Planing blade blunt/worn

Planing blade filled with chips

Uneven feed

Replace or sharpen blade

Remove chips

Feed the workpiece with constant pressure and at

reduced speed

Machined surface too

rough

Workpiece contains too much

moisture

Dry workpiece

Machined surface

cracked

Workpiece was machined against

the grain

Too much material planed at one

pass

Machine the workpiece from the opposite direction

Machine the workpiece in several passes

Workpiece speed too

low during thicknessing

Workpiece was machined against

the grain

Too much material planed at one

pass

Clean bench top and apply a thin coating of lubricant

wax

Repair transport rollers

Set the lever for the thicknessing setting to the top

position

When thicknessing,

chip ejection obstructed

(without dust extractor).

Too much chip removal

Blunt knives.

Wood too humid.

Reduce chip removal.

Replace knives

Dry workpiece

When surface planing,

chip ejection obstructed

(without dust extractor)

Too much chip removal

Too fast feed

Blunt knives.

Wood too humid.

Reduce chip removal.

Reduce infeed speed.

Replace knives.

Dry workpiece

With surface planing

and thicknessing, chip

ejection obstructed (with

dust extractor).

Suction performance too weak.

Use a dust extractor unit having an airflow rate at the

suction connection of at least 20 m/s.

Summary of Contents for 5902210901

Page 2: ... www scheppach com service scheppach com 49 08223 4002 99 49 08223 4002 58 2 ...

Page 143: ... www scheppach com service scheppach com 49 08223 4002 99 49 08223 4002 58 143 ...

Page 144: ... www scheppach com service scheppach com 49 08223 4002 99 49 08223 4002 58 144 ...

Page 145: ... www scheppach com service scheppach com 49 08223 4002 99 49 08223 4002 58 145 ...

Page 147: ... www scheppach com service scheppach com 49 08223 4002 99 49 08223 4002 58 147 ...