www.scheppach.com /

service@scheppach.com /

+(49)-08223-4002-99 /

+(49)-08223-4002-58

GB

| 25

The V-belt must lie in the same groove on the

upper and lower drive pulley.

Note: The two gearing covers (20) are equipped

with an interlock switch (26). The interlocking

switches (26) are actuated automatically when

the gearing covers (20) are closed. The device

cannot be switched on if a gearing cover (20) is

not closed correctly.

7. Loosen the locking screw (21) and lower the lever

with the motor unit to tighten the V-belt.

8. Tighten the locking screw (21).

9. Close the gearing covers (20). Secure the gearing

covers with the locking screws (19).

Securing the workpiece

Securing with the 4-prong centre tip (1) and tail-

stock (5) (Fig. 1)

1. Draw a diagonal line at both ends of the work-

piece to locate the centre. The centre is where

the lines meet.

Make a centring hole where the

4-prong centre tip and tailstock are to meet the

workpiece. This ensures a better hold.

2.

Make an approx. 2 mm deep saw cut along the

diagonal to enable the 4-prong centre tip (1) to

grip better.

3.

Fit the dismounted 4-prong centre tip (1) central

-

ly to the centre of the workpiece.

Lightly tap the

4-prong centre tip (1) into the workpiece with a

mallet (not included in the scope of delivery).

Take

care to protect the thread of the 4-prong centre tip

(1) with a wooden board, for example.

4.

Remove the 4-prong centre tip (1) from the work

-

piece again.

5. Then (re)mount the 4-prong centre tip (1) onto the

device.

Note: The mounting and dismounting of the

4-prong centre tip can be found in the chapter

“Mounting/changing the workpiece holders”.

6. Position the workpiece on the 4-prong centre tip

(1).

Make sure that the 4-prong centre tip (1) en

-

gages with the notch, otherwise secure clamping

is not guaranteed.

7. Loosen the lever (8) of the tailstock.

8. Slide the tailstock towards the 4-prong centre tip

(1) until it makes firm contact with the workpiece

to clamp it.

9.

Fix the tailstock by pushing the lever (8) down.

10.

Use the hand wheel (6) for fine adjustment.

11.

Fix the position of the handwheel with the coun

-

ternut (4).

10. Operation

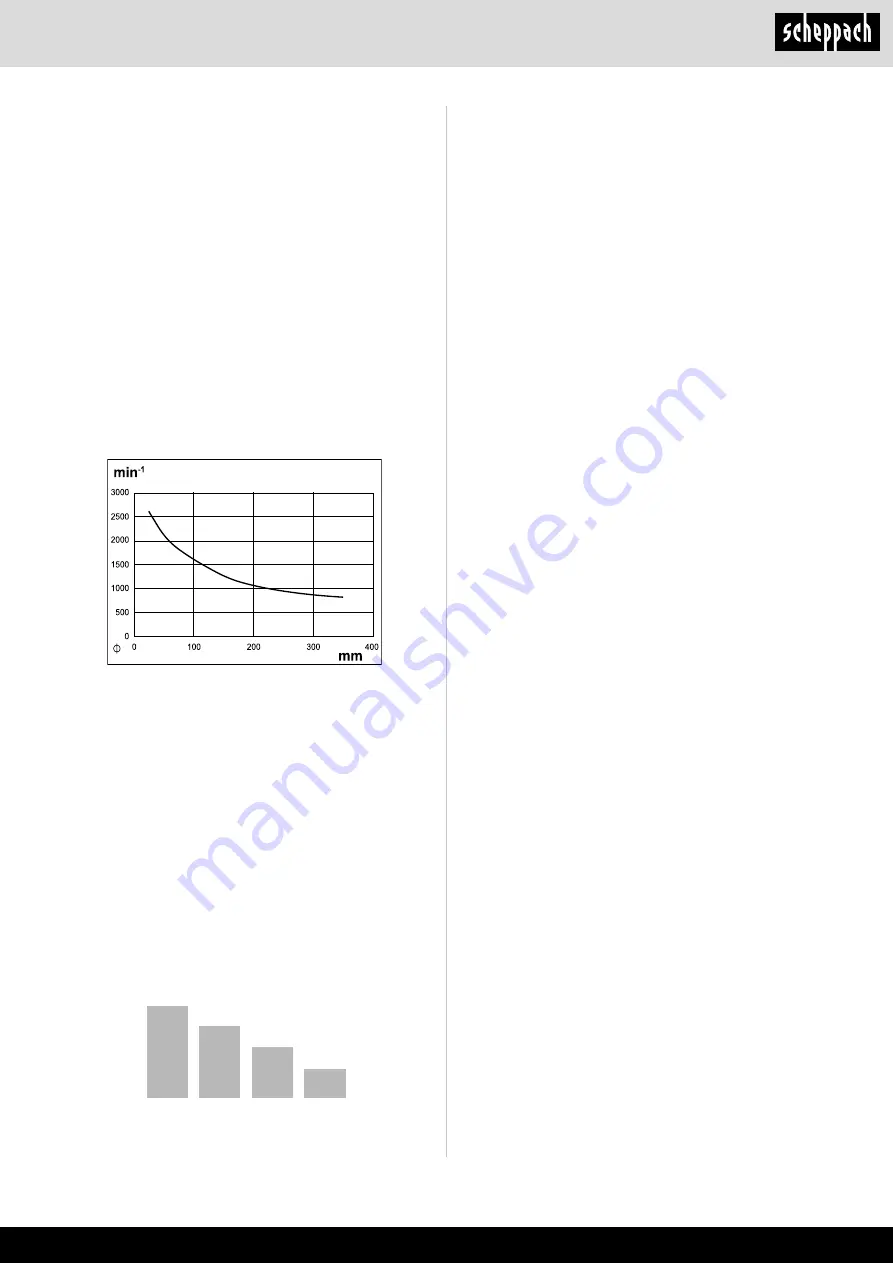

Selecting the speed (Fig. 3)

m

ATTENTION!

The mains plug shall not be plugged in when ad-

justing the speed.

Select the correct speed:

•

With new workpieces, select a low speed first.

In

-

crease the speed as the weight of the workpiece

increases.

• The selection of the correct speed depends on

several factors, e.g. material, diameter, length and

unbalance of the workpiece.

In principle: Choose

a low speed for hard timber, non-round, long or

large-diameter workpieces.

•

Use the table as a guide when selecting the speed:

The workpiece diameter is indicated on the x-axis.

The speed can be read off the y-axis.

Go up vertically

from the diameter of the workpiece and read off the

speed where an imaginary perpendicular line meets

the curve.

1. Loosen the two locking screws (19) on the two

gearing covers (20).

2. Open the gearing covers (20).

3. Loosen the locking screw (21) of the motor unit

with the Allen key (12).

4.

Lift the motor unit (22) by operating the lever (23)

to relieve the load on the V-belt (25).

5.

Fix the motor unit (22) by tightening the locking

screw (21).

6. Place the V-belt (25) in the desired groove of the

drive pulley (24) to achieve the specified speed:

890

1260

1760

2600