17

www.scheppach.com

service@scheppach.com

+(49)-08223-4002-99

+(49)-08223-4002-58

www.scheppach.com

service@scheppach.com

+(49)-08223-4002-99

+(49)-08223-4002-58

A kickback is caused by incorrect use or misuse of the

power tool. This can be avoided by taking proper pre

-

cautions as given below.

•

Hold the power tool firmly in both hands and

position your arms so they can absorb the force

of a kickback. Always use the additional handle,

if available, so you have the maximum control

over the kickback force or reaction torques at

full speed.

By taking adequate precautions, the

operator can stay in control of the kickback and

reaction torques.

•

Never hold your hand close to a rotating acces-

sory tool.

The accessory tool could hit your hand in

the case of a kickback.

•

Avoid the area in front of and behind the rotating

cutting disc.

The kickback will force the power tool

in the opposite direction to the direction of rotation of

the grinding disc at the blockage.

•

Take special care when working around corners,

sharp edges, etc. Avoid allowing the accessory

tool to bounce back from the workpiece or jam.

The rotating accessory tool is more likely to jam in

corners or sharp edges or if it bounces. This can

cause a loss of control or kickback.

•

Do not use a toothed or chain saw blade or seg-

mented diamond-coated disc with more than 10

mm wide slits.

Such accessory tools cause a kick

-

back or loss of control over the power tool.

•

Avoid cutting disc jams or excessive contact

pressure. Do not make any excessively deep

cuts.

Overloading the cutting disc increases the

stress and likelihood of tilting or jamming and thus

the possibility of kickback or breakage of the grin

-

ding tool.

•

If the cutting disc jams or you stop working,

switch the tool off and hold it steady until the

disc has completely stopped turning. Never att-

empt to pull a rotating cutting disc out of a cut.

This could lead to kickback.

Identify and remove

the cause of the jam.

•

Do not switch the power tool back on as long as

it is in the workpiece. Allow the cutting disc to

reach its full speed before you carefully continue

the cut.

Otherwise, the disc may jam, jump out of

the workpiece or cause kickback.

•

Support panels or large workpieces to reduce

the risk of the cutting disc jamming and causing

a kickback.

Large workpieces can bend under their

own weight. The workpiece must be supported on

both sides, namely in the vicinity of the cut and also

at the edge.

•

Be particularly careful when making „pocket

cuts“ into existing walls or other obscured are-

as

. The inserted cutting disc may cut into gas or

water pipes, electrical wiring or other objects that

can cause kickback.

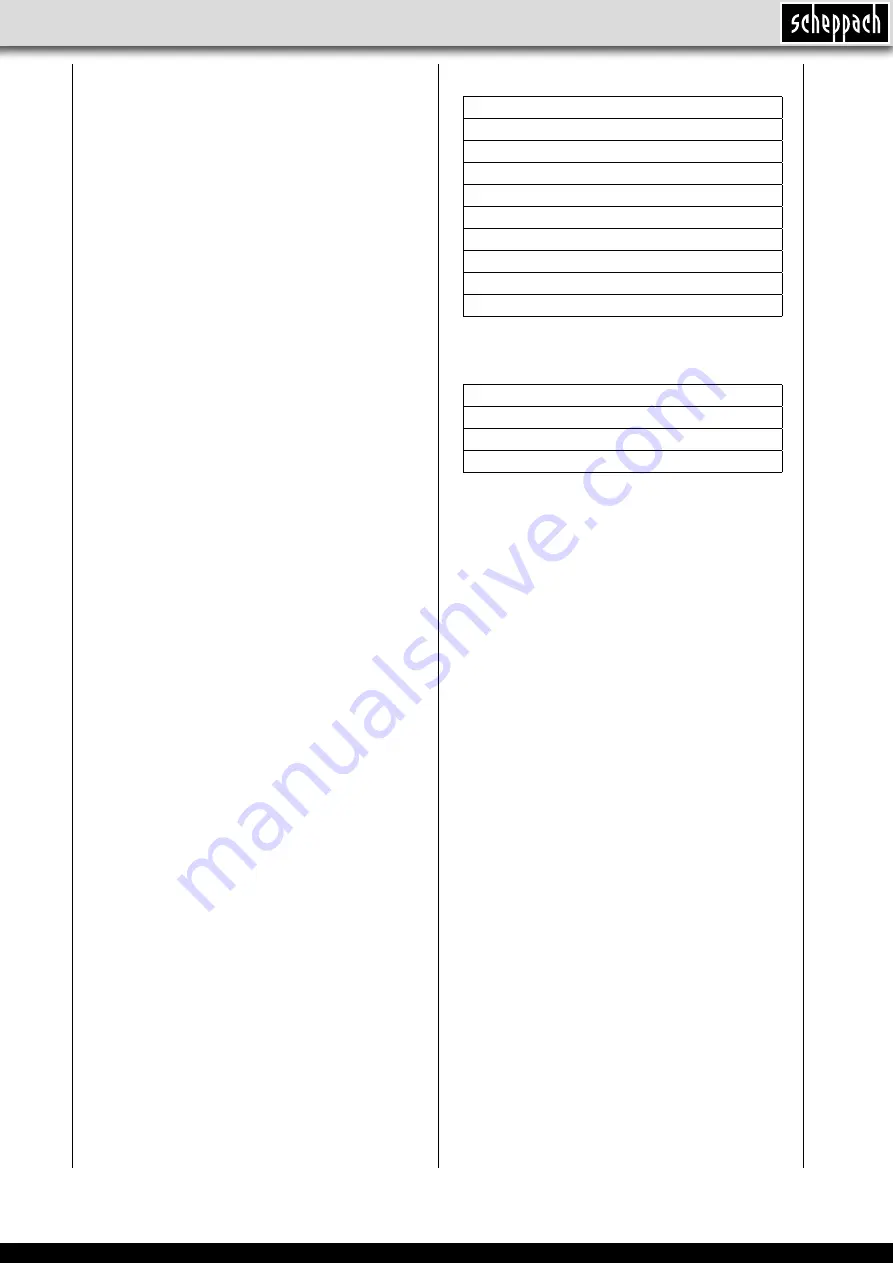

Technical data

Input voltage

230 V~, 50 Hz

Power consumption

1350 W

Rated speed

9000 /min

Disc sizes Ø

125 mm

Central fixing bore

22.2 mm

Groove depth

0 - 30 mm

Groove widths

8 - 26 mm

Thread

M14

Protection class

II

Weight

4 kg

Noise

Total noise values determined in accordance with EN

60745.

sound pressure level L

pA

97.6 dB(A)

uncertainty K

pA

3 dB(A)

sound power level L

WA

108.6 dB(A)

uncertainty K

WA

3 dB(A)

Wear hearing protection.

The effects of noise can cause a loss of hearing.

Total vibration values (vector total of three directions)

determined in accordance with EN 60745. Details of

vibration values (when cutting off a concrete plate):

Main handle: a

h

= 6,417 m/s

2

Uncertainty K = 1,5 m/s

2

NOTE:

The vibration level specified in these instruc

-

tions has been measured in accordance with a stan

-

dardised measuring procedure specified in EN 60745

and can be used to make equipment comparisons.

The specified vibration emission value can also be

used to make an initial exposure estimate.

m

WARNING!

The vibration level varies in accordance

with the use of the power tool and may be higher than

the value specified in these instructions in some ca

-

ses. There is a risk of underestimation of the vibration

load if the power tool is used regularly in this manner.

Try to keep the vibration loads as low as possible.

Measures to reduce the vibration load are, e.g. wea

-

ring gloves and limiting the working time. Wherein all

states of operation must be included (e.g. times when

the power tool is switched off and times where the po

-

wer tool is switched on but running without load).

Residual risks

Even if you use this electric power tool in ac-

cordance with instructions, certain residual risks

cannot be rules out. The following hazards may

arise in connection with the equipment’s const

-

ruction and layout:

•

Lung damage if no suitable protective dust mask is

used.

•

Damage to hearing if no suitable ear protection is

used.