www.scheppach.com /

service@scheppach.com /

+(49)-08223-4002-99 /

+(49)-08223-4002-58

GB | 21

10.7 Service information

Please note that the following parts of this product

are subject to normal or natural wear and that the fol-

lowing parts are therefore also required for use as

consumables.

Wear parts*: Belt, clutch

* Not necessarily included in the scope of delivery!

11. Disposal and recycling

The unit is supplied in packaging to prevent its being

damaged in transit. This packaging is raw material

and can therefore be reused or can be returned to

the raw material system.

The unit and its accessories are made of various

types of material, such as metal and plastic. De-

fective components must be disposed of as special

waste. Ask your dealer or your local council.

Old devices must not be disposed of with house-

hold waste!

This symbol indicates that this product must

not be disposed of together with domestic

waste in compliance with the Directive

(2012/19/EU) pertaining to waste electrical

and electronic equipment (WEEE).

This product must be disposed of at a designated

collection point. This can occur, for example, by

handing it in at an authorised collecting point for the

recycling of waste electrical and electronic equip-

ment. Improper handling of waste equipment may

have negative consequences for the environment

and human health due to potentially hazardous sub-

stances that are often contained in electrical and

electronic equipment. By properly disposing of this

product, you are also contributing to the effective

use of natural resources. You can obtain information

on collection points for waste equipment from your

municipal administration, public waste disposal au-

thority, an authorised body for the disposal of waste

electrical and electronic equipment or your waste

disposal company.

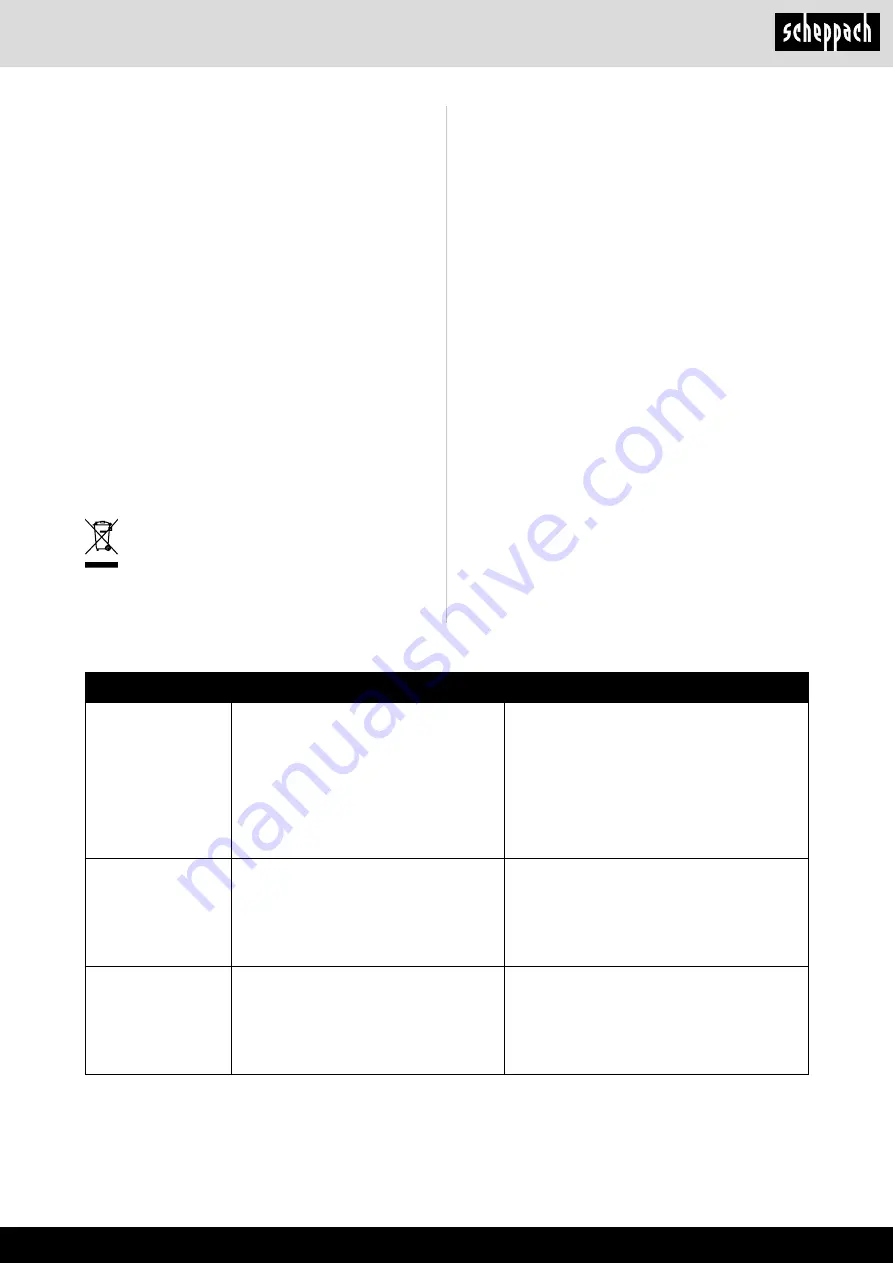

12. Troubleshooting

Fault

Possible cause

Remedy

The compressor

does not start.

• No supply voltage.

•

Insufficient supply voltage.

• Outside temperature is too low.

• Motor is overheated.

• Check the supply voltage, the power plug

and the socket-outlet.

• Make sure that the extension cable is not

too long. Use an extension cable with large

enough wires.

• Never operate with an outside temperature of

below +5° C.

• Allow the motor to cool down. If necessary,

remedy the cause of the overheating.

The compressor

starts but there is no

pressure.

• The non-return valve leaks.

• The seals are damaged.

• The drain plug for condensation water

(1) leaks.

• Have a service centre replace the non-return

valve.

• Check the seals and have any damaged

seals replaced by a service centre.

• Tighten the screw by hand. Check the seal

on the screw and replace if necessary.

The compressor

starts, pressure is

shown on the pres-

sure gauge, but the

tools do not start.

• The hose connections have a leak.

• A quick-lock coupling has a leak.

•

Insufficient pressure set on the pressure

regulator (7).

• Check the compressed air hose and tools

and replace if necessary.

• Check the quick-lock coupling and replace if

necessary.

• Increase the set pressure with the pressure

regulator.