27

GB

Transport

To transport the machine, empty the petrol tank as

described in section 8 draining fuel. Clean coarse dirt

off the equipment with a brush or hand brush.

12. Disposal and recycling

The equipment is supplied in packaging to prevent it

from being damaged in transit. The raw materials in

this packaging can be reused or recycled. The equip

-

ment and its accessories are made of various types

of material, such as metal and plastic. Defective

components must be disposed of as special waste.

Ask your dealer or your local council.

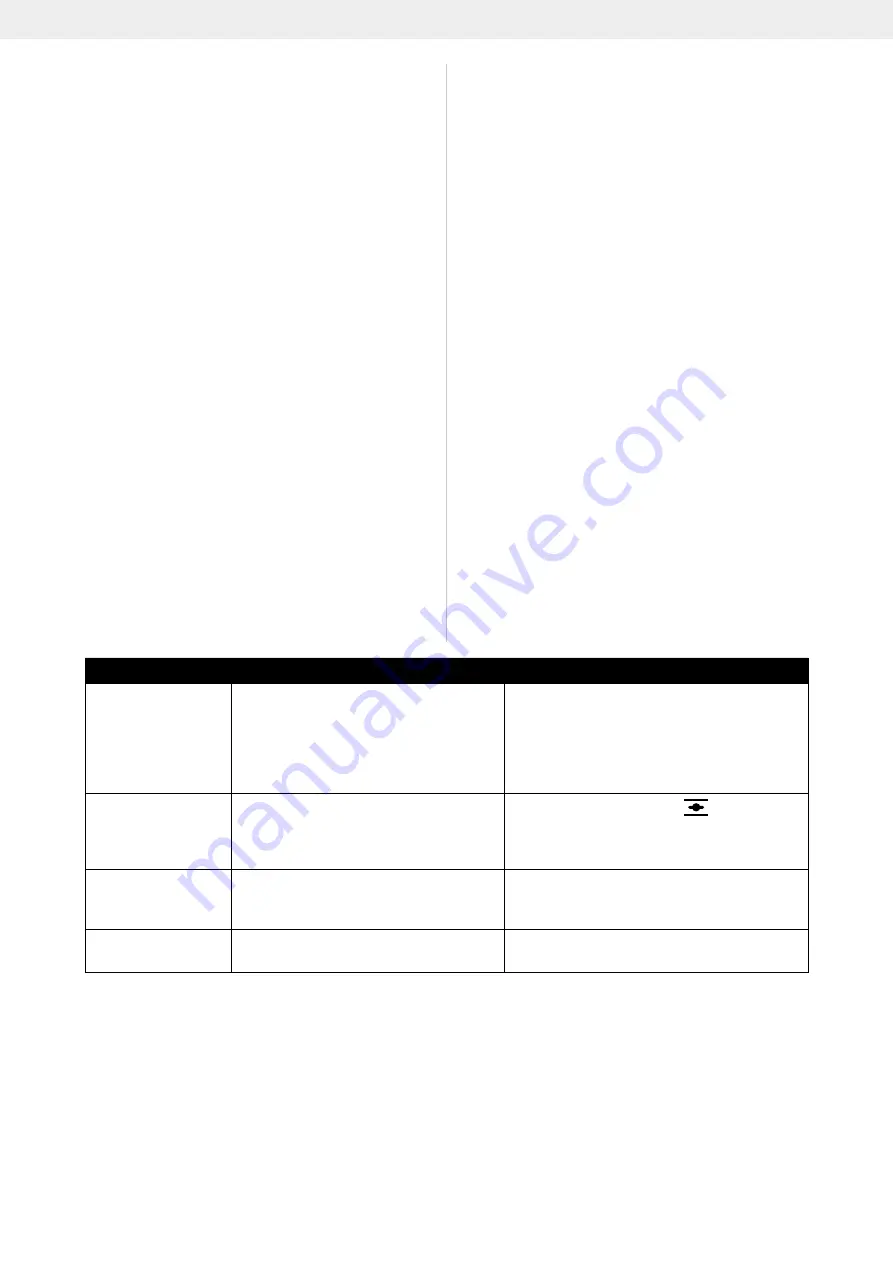

13. Troubleshooting

The table below contains a list of fault symptoms and

explains what you can do to remedy the problem if

your equipment fails to work properly. If the problem

still persists after working through the list, please

contact your nearest service workshop.

Important hint in case of sending the equipment

to a service station:

Due to security reasons please see to it that the

equipment is sent back free of oil and gas!

Fault

Possible cause

Remedy

The equipment does

not start

• Correct starting procedure not followed

• Sooted or damp spark plug

• Incorrect carburetor setting

•

Blade or nylon cutter mounted incorrectly

• No fuel in the tank

• Follow the instructions for starting

• Clean the spark plug or replace it with a new

one

• Contact an authorized customer service outlet

•

Reassemble the blade or nylon cutter

• Check the fuel level

The equipment starts

but does not develop

its full power

• Incorrect choke lever setting

•

Soiled air filter

• Incorrect carburetor setting

• Cutting blade blunt

• Set the choke lever on the position

•

Clean the air filter

• Contact an authorized customer service outlet

• Have cutting blade resharpened /replaced

The engine does not

run smoothly

• Incorrect electrode gap on the spark plug

• Incorrect carburetor setting

• Clean the spark plug and adjust the electrode

gap, or fi t a new spark plug

• Contact an authorized customer service outlet

If the temperature of

machines is too high

• Engine is overloaded

• Insure the machines have rest at regular time

This can cause problems when starting up the equip-

ment and may require expensive repairs.

1

Slowly remove the fuel tank cap to release any

pressure that may have formed in the tank. Care

-

fully empty the tank.

2 To remove the fuel from the carburetor, start the

engine and let it run until the equipment stops.

3 Leave the engine to cool (approx. 5 minutes).

4 Remove the spark plug (see section 10 Change

and clean the spark plug).

5 Add one teaspoon of 4-stroke engine oil into the

combustion chamber. Slowly pull the starter cord

several times to apply a layer of oil to all internal

components. Fit the spark plug again.

Note:

Store the equipment in a dry place and far

away from possible ignition sources such as an oven,

a gas-fi red hot water boiler, a gas-fi red dryer, etc.

Putting the equipment back into operation

1 Remove the spark plug (see section 10 Change

and clean the spark plug).

2

Quickly tug on the starter cord to remove excess

oil from the combustion chamber.

3 Clean the spark plug and check that the electrode

gap is correct, or insert a new spark plug with the

correct electrode gap.

4 Prepare the equipment for operation.

5 Fill the tank with proper fuel locations.

6 Check it the oil level.