WARNING! Avoid contact with the terminals on the

plug when installing (removing) the plug to (from)

the power supply outlet. Contact will cause a se-

vere electrical shock.

Using an Extension Lead

The use of any extension lead will cause some loss of pow-

er. To keep this to a minimum and to prevent overheating

and possible motor burn-out, ask advice from a qualified

electrician to determine the minimum wire size of the ex-

tension lead.

The extension lead should be equipped with an earthed

type plug that fits the power supply outlet at one end, and

with an earthed type socket that fits the plug of this ma-

chine at the other end.

Mounting the Tool

Note:

We highly recommend that you bolt this mitre saw secure-

ly to a work bench to gain the maximum stability of your

machine.

1. Locate and mark the four bolt holes on the bench.

2. Drill the bench with a ø 10 mm drill bit,

3. Bolt the mitre saw on to the bench with bolts, wash-

ers and nuts. Note that these fasteners are not sup-

plied with the machine.

Operating the Tool

WARNING! Never connect the plug to the power

source outlet until all Installations and adjust-

ments are completed and you have read and un-

derstood the safety and operational instructions.

Basic Pullover Mitre Saw Operations

1. Always use the clamp

①

to hold the work piece firmly.

Six holes are provided for the clamp. The End Stop

➁

is useful when making repetitive cuts.

(Fig. 12)

2. Always position the work piece against the fence. Any

piece that is bowed or warped and cannot be held flat

on the table or against fence may trap the blade and

should not be used.

3. Never place hands near the cutting area. Keep hands

outside the ”No Hands Zone” which includes the en-

tire table and is labelled by ”No Hands” symbols.

WARNING! To avoid injury from materials being

thrown, unplug the saw to avoid accidental start-

ing, and then remove small materials.

Chop Cut

1. For chop cutting, slide the cutting head to the rear

position as far as it will go, and lock the carriage

➀

by

the lock handle

➁

.

(Fig. 14)

Mitre Cut

1. Make sure the extension fence is secured in the cor-

rect position.

(Fig. 6)

2. Loosen the Mitre Lock Knob and move the table to

the desired angle. For angles of 0°, 15°, 22.5°,

31.6°, and 45°, the table will stop by itself. Tighten

the mitre lock knob.

(Fig. 13)

3. Activate the switch, then press the blade guard lock

lever to lower the cutting head down.

Bevel Cut

1. Turn the Extension Fence and install it far from the

saw blade.

(Fig. 7)

2. Loosen the bevel lock handle and move the cutting

head to the desired angle. Tighten the bevel lock han-

dle.

3. Activate the switch, then press the blade guard lock

lever to lower the cutting head down.

Note:

1. A special bevel angle 33.9° stop device is fitted to

this mitre saw for special crown moulding. When this

angle is required, place the lock pin

➀

into the slot

whilst turning the bevel angle to 33.9°.

(Fig. 15)

Compound Cut

1. A compound cut is a combination of mitre cut and

bevel cut. Refer to the above procedures to perform

this cut.

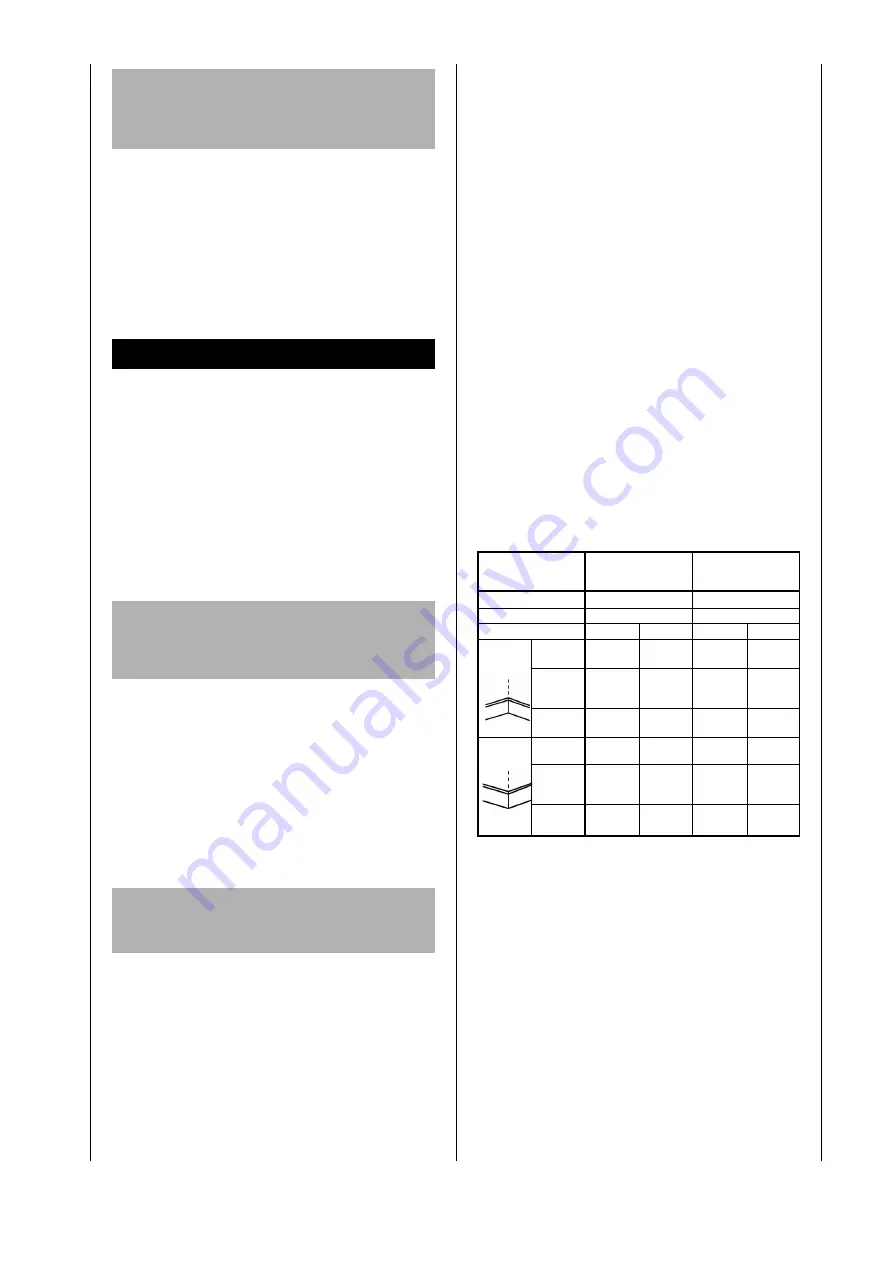

Base Moulding

1. Base moulding can be cut vertically against fence or

flat on the table. Follow the table below for reference.

Crown Moulding Cut

1. Crown moulding can only be cut flat on the table us-

ing this mitre saw.

(Fig. 16)

2. This mitre saw has special mitre stops of 31.6° left

and right and a bevel stop of 33.9° for a special

crown moulding

①

i.e. 52° between the back of the

moulding and the top flat surface that fits against the

ceiling; 38° between the back of the moulding and

the bottom flat surface that fits against the wall

(Fig.

17).

Refer to the following table for this crown mould-

ing cut.

Note:

1. These special stops cannot be used with 45° crown

moulding.

2. Since most rooms do not have angles of exactly 90°,

fine tuning is needed and always take a test cut to

confirm the correct angles.

3

SETTINGS

Extension Fence

Bevel Angle

Moulding Position

Vertical Position

(Back of moulding is flat

against the fence)

Close to the blade

0°

Horizontal Position

(Back of moulding is flat

on the table)

Far from the blade

45°

Inside

corner

Outside

corner

Mitre

Angle

Moulding

position

Finished

side

Mitre

Angle

Moulding

Position

Finished side

Left side

Left at 45°

Bottom

against

table

Keep left

side of cut

Right at 45°

Bottom

against

table

Keep left

side of cut

Right side

Right at 45°

Bottom

against

table

Keep right

side of cut

Left at 45°

Bottom

against

table

Keep right

side of cut

Left side

0°

Top

against

fence

Keep left

side of cut

0°

Bottom

against

fence

Keep right

side of cut

Right side

0°

Bottom

against

fence

Keep left

side of cut

0°

Top

against

fence

Keep right

side of cut

Left

Right

Right

Left