www.scheppach.com

service@scheppach.com

+(49)-08223-4002-99

+(49)-08223-4002-58

16 І 112

Technical data

Mains connection

230V 50Hz

Motor rating W

1500

Operating mode

S1

Compressor speed min

-1

2900 min

-1

Pressure vessel capacity (in lit-

ers)

50

Operating pressure

10 bar

Theoretical intake capacity (l/min) 200 l/min

sound power level L

WA

96 dB(A)

uncertainty K

WA

2,23 dB(A)

Protection type

IP20

Weight of the unit in kg

31 kg

The noise emission values were measured in accord-

ance with EN ISO 2151.

Wear hearing protection.

The effects of noise can cause a loss of hearing.

Before starting the equipment

Before you connect the equipment to the mains supply

make sure that the data on the rating plate are identical

to the mains data.

•

Check the equipment for damage which may have

occurred in transit. Report any damage immediately

to the transport company which was used to deliver

the compressor.

•

Install the compressor near the point of consumption.

•

Avoid long air lines and supply lines (extension ca-

bles).

•

Make sure that the intake air is dry and dustfree.

•

Do not install the compressor in a damp or wet room.

•

The compressor may only be used in suitable rooms

(with good ventilation and an ambient temperature from

+5 °C to 40 °C). There must be no dust, acids, vapors,

explosive gases or inflammable gases in the room.

•

The compressor is designed to be used in dry rooms.

It is prohibited to use the compressor in areas where

work is conducted with sprayed water.

Attachment and operation

n

Important!

You must fully assemble the appliance before using

it for the first time!

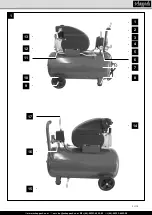

Fitting the wheels (10)

•

Fit the supplied wheels (10) as shown in Fig. 4.

Fitting the supporting foot (8)

•

Fit the supplied supporting foot (8) as shown in Figure 5.

Installation of the air filter (14)

•

Remove the transport plug and attach the air filter

(Figure 7/14) on the unit by turning clockwise.

•

Solve for maintenance the air filter (14) by turning

counter-clockwise..

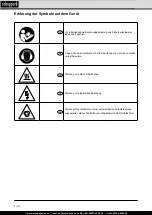

explosions in the compressor pump.

•

When releasing the hose coupling, hold the hose cou-

pling piece with your hand. This way, you can protect

yourself against injury from the rebounding hose.

•

Wear safety goggles when working with the blow-out

pistol. Foreign bodies or blown off parts can easily

cause injuries.

•

Do not blow at people with the blow-out pistol and

do not clean clothes while being worn. Risk of injury!

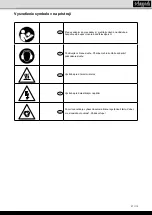

Safety information for paint spraying

•

Do not process any paints or solvents with a flash

point below 55° C. There is a risk of explosion!

•

Do not heat up paints or solvents. There is a risk of

explosion!

•

If hazardous liquids are processed, wear protective

filter units (face guards). Also, adhere to the safety

information provided by the manufacturers of such

liquids.

• The details and designations of the Ordinance on

Hazardous Substances, which are displayed on the

outer packaging of the processed material, must be

observed.

•

Additional protective measures are to be undertaken

if necessary, particularly the wearing of suitable cloth-

ing and masks.

•

Do not smoke during the spraying process and/or in

the work area. There is a risk of explosion! Paint va-

pors are easily combustible.

•

Never set up or operate the equipment in the vicin-

ity of a fire place, open lights or sparking machines.

•

Do not store or eat food and drink in the work area.

Paint vapors are harmful to your health.

•

The work area must exceed 30 m

3

and sufficient ven-

tilation must be ensured during spraying and drying.

Do not spray against the wind. Always adhere to the

regulations of the local police authority when spraying

combustible or hazardous materials.

•

Do not process media such as white spirit, butyl al-

cohol and methylene chloride with the PVC pressure

hose.These media will destroy the pressure hose.

Operating pressure vessels

•

You must keep your pressure vessel in good working

order, operate the vessel correctly, monitor the vessel,

carry out necessary maintenance and repair work im-

mediately and meet the relevant safety precautions.

•

The supervisory authority may enforce essential con-

trol measures in individual cases.

•

A pressure vessel is not allowed to be used if it has

faults or deficiencies that can endanger workers or

third parties.

•

Check the pressure vessel for signs of rust and dam-

age each time before using. Do not use the com-

pressor with a damaged or rusty pressure vessel. If

you discover any damage, then please contact the

customer service workshop.

Do not lose these safety instructions