25

pred vsako uporabo. Prenizek nivo olja lahko poškoduje

oljno črpalko. Pravilni nivo olja je nekje 10 do 20 mm pod

površino rezervoarja.

Opomba: Nivo olja mora biti preverjen vsakič ko potegne

-

mo nazaj cepilni nož. Merilna palica za olje je locirana na

rezervoarju za olje v odprtini izvijača A (Slika 9) in ima

dve zarezi. Če je nivo olja na nižji zarezi to pomeni, da

je nivo olja na minimumu. Če je tako morate olje takoj

dodati. Zgornja zareza pomeni, da je olja dovolj.

Kdaj naj zamenjamo olje?

Prva menjava olja naj bo po 50 delovnih urah, nato pa po

500 delovnih urah.

Menjava olja

1

Popolnoma izvlecite cepilni steber.

2

Naravnajte cepilnik z dvema kolesoma od tal na paleto

ali nekaj podobnega.

3

Previdno upognite cepilnik (za to potrebujete dva

človeka) proti zadnji strani dokler se ne naravna na

pokrov Podenj položite krpo ali karton, da se izognete

morebitnim poškodbam.

4

Postavite pod polnilni čep A posodo z volumnom vsaj

8 litrov .

5

Odprite polnilni čep A, da olje lahko izteče ven.

6

Postavite cepilnik nazaj na noge.

7 Napolnite ga s 7 litri novega hidravličnega olja preko

čistega lija.

8

Zatesnite oljni čep.

9

Preverite nivo olja pred prvim zagonom.

Odstranite odpadno olje na pravilen način v zbiral

-

nik odpadnega olja ali ga odpeljite na mesto zbiranja.

Prepovedano je izlivanje olja v tla ali mešanje le tega

z drugimi odpadki.

Priporočamo sledeča hidravlična olja

Aral Vitam gf 22

BP Energol HLP-HM 22

Mobil DTE 11

Shell Tellus 22

ali olja podobne kvalitete

Ne uporabljajte drugega tipa olja, ker to lahko vpliva na

funkcijo hidravličnega cilindra.

Rezervni cepilni nož

Preden uporabite rezervni cepilni nož ga morate rahlo

namastiti. Ponovite postopek vsakih 5 ur delovanja na

-

prave. Previdno nanesite maščobo ali poškropite z oljem

v pršilu. Rezilo ne sme nikoli delovati na suho.

Hidravlični sistem

Hidravlični sistem je zaprt sistem z rezervoarjem olja, olj

-

ne črpalke in kontrolnega valja.

Sistem je sestavljen, ko je stroj pripeljan in se ga ne sme

spreminjati ali z njim manipulirati.

Redno preverjajte nivo olja.

Prenizek nivo olja lahko poškoduje oljno črpalko.

Redno preverjajte hidravlične stike in spoje zaradi tesnje

-

nja. Po potrebi ponovno zatesnite.

fore every use. Too low an oil level can damage the oil

pump. The correct oil level is approx. 10 to 20 mm below

the oil tank surface.

Note:

The level of oil must be checked when the riving

knife is pulled back.

The measuring stick for the oil is

located on the oil tank in the funnelling screw A (Fig. 9)

and has two notches.

If the oil level is at the lower notch,

then the oil level is at a minimum. Should this be the

case, oil must be immediately added. The upper notch

indicates the maximum oil level.

When must the oil be changed?

First oil change after 50 operating hours, then every 500

operating hours.

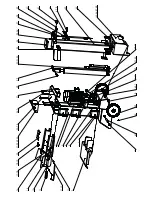

Changing the oil

1

Fully retract the splitting column.

2

Place the splitter with the two wheels off the floor onto

a pallet or something similar.

3

Carefully tilt the splitter (two people required) to the

rear until it comes to lie on the cover plate. Put a cloth

or a board underneath in order to avoid damages.

4

Put a basin having a volume of at least 8 litres

underneath the filler plug A.

5

Open the filler plug A so that the oil can come off.

6

Place the splitter on its feet again.

7

Fill in 7 litres of new hydraulic oil using a clean funnel.

8

Retighten the filler plug.

9

Check the oil level after the first switching on.

Dispose of the used oil in a correct manner at a public col-

lection facility. It is prohibited to drop old oil on the ground

or to mix it with waste.

We recommend the following hydraulic oils:

Aral Vitam gf 22

BP Energol HLP-HM 22

Mobil DTE 11

Shell Tellus 22

or oils of same quality.

Do not use any other types of oil

as they would influence

the function of the hydraulic cylinder.

Splitting spar

Before use, the spar of the splitter must be slightly

greased. Repeat this procedure every five operating

hours. Slightly apply grease of oil spray. The spar may

never run dry.

Hydraulic system

The hydraulic unit is a closed system with oil tank, oil

pump and control valve.

The system is complete when the machine is delivered,

and may not be changed or manipulated.

Regularly check the oil level.

Too low an oil level damages the oil pump.

Regularly check the hydraulic connections and bolts for

tightness. Retighten if necessary.

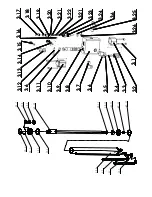

Summary of Contents for HL1000v

Page 2: ......

Page 3: ...D Holzspalter 4 35 GB Log splitter SLO Hidravli ni cepilnik...

Page 33: ......

Page 34: ......

Page 35: ...30 4 30 1 30 9 32 30 10 30 6 30 7 30 13 30 8 31 30 3 30 2 30 11 30 5 30 14 30 15 30 12...