of dangers, in compliance with the operating

instructions! Failures which can affect safety

in particular must be removed straight away!

• The manufacturer’s stipulations concerning

safety, work and maintenance as well as the

measurements specified in Technical data,

must be complied with.

• The relevant accident prevention stipulations

and other widely recognised safety rules

must be observed.

• The machine may be used, maintained or

repaired only by expert personnel who are

familiar with it and its dangers. Unautho-

rised changes to the machine invalidate the

manufacturer’s liability for damages resulting

from this.

• The machine may be used only with the

manufacturer’s original accessories and

original tools.

• Every use beyond that is deemed as not

intended. The manufacturer is not liable

for damage resulting from this, the risk lies

exclusively with the user.

Residual risks

m

• the machine has been built according to

the latest technology and recognised safety

rules. However, individual residual risks can

occur when working: Risk of injury to fingers

and hands from the rotating cutterblock

during incorrect handling of the work piece.

Never reach with your hands under the

cutter block guard when guiding the work

piece! Do not pull the work piece back over

the unguarded cutter block.

• Injuries when the work piece is ejected

during incorrect mounting or handling, such

as working without a fence.

• Health risk from wood dust and shavings.

• Make sure you wear personal protective

equipment such as eye protection and a

dust mask. Use an extraction unit!

• Health risk from noise during work, the per-

mitted noise level is exceeded. Make sure

you wear personal protective equipment

such as hearing protection.

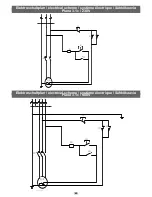

• Electrical hazards when unsuitable electric

connections are used

• Process chosen wood only, without imper-

fections such as: Knots, transverse cracks,

surface cracks, foreign objects (nails,

screws). Flawed wood creates a risk during

work.

• Furthermore, despite all measures taken,

residual risks can occur that are not obvi-

ous.

• Residual risks can be minimised by comply-

ing with the safety notices and the intended

use as well as the operating instructions

overal

• Drawing-in/trapping hazard by power feed

mechanism.

• Squeezing hazard by work piece power-

outfeed.

Set-up

Prepare the work place where the power tool

will be used. Make sufficient space so that

safe and uninterrupted work is ensured. The

power tool has been designed for work in

closed rooms, and it has to be set up on an

even, level, solid surface in a stable position.

Fixing the machine on level hard concrete

floor before operation.

Equipment fig. 1

1 Jointer table fixed

2 Jointer table adjustable

3 Jointing fence

4 Cutterblock cover

5 Table adjustment lever

6 Locking handle for thicknessing table

7 Infeed locking lever

8 Extraction hood

9 Table locking system

10 Thicknessing table clamping

11 Height adjustment caster

12 Handles to adjust the height of the

jointer tables

13 On-/off-switch

Assembly

Due to packaging reasons, your planer is

not completely assembled.

The planer must not be lifted by the jointer

tables!

Attaching and adjusting of base plates

fig. 2

Attach 4 base plates to the bottom of the

frame,

Slightly tighten hexagon nuts by hand.

In order to balance out an uneven surface,

loosen the lock nuts and turn the base plates

in or out accordingly.

Tighten the lock nut again.

Warning!

Make sure you align the machine using a

spirit level.

Attaching the jointing fence fig. 3

Insert the jointing fence (3) in the track and

tighten it with the clamping lever (A).

Adjusting the jointing fence fig. 3.0, 3.1

1. Loosen the clamping lever (B).

2. Using a try-square, determine the 90° angle

of the jointer table to the stop surface,

3. tighten the clamping lever (B).

4. Loosen the lock nut, adjust the fence with

the cylinder screw (C).

5. Tighten the lock nut again.

Warning!

The jointing fence always has to be se-

cured safely.

Clamping is carried out with the clamping

levers (A + B) fig 3.1.

Attaching the cutterblock cover fig. 4

Attach and tighten the cutterblock cover on the

side of the jointer table with 2 Allen screws.

The cutterblock cover can be turned away wit-

hout tools by pulling the cam lever up, turning

the cutterblock cover away,

and pushing the cam lever down again.

For Plana 4.1 and 6.1 fig. 12, 12.1

1. Loosen 1 recessed head screw (M) each

on both sides of the rear panel,

2. lift the rear panel slightly and take it off.

3. Loosen the lock nut (K), tension the belt by

turning the hexagon screw (L), tighten the

lock nut again.

4. Insert the rear panel and secure it again

with the 2 recessed head screws.

For Plana 3.1 fig. 13, 13.1

1. Remove 6 recessed head screws left and

right on the rear panel.

2. Loosen 4 mounting screws (M) on the

motor.

3. Use a wooden board as a lever between the

motor and the casing for tensioning.

4. Tighten the 4 mounting screws again.

5. Check the belt tension after tightening.

6. Re-attach the rear panel.

GB

18

Summary of Contents for plana 3.1c

Page 4: ...1 1 3 4 2 6 5 12 10 8 9 13 7 11 4...

Page 5: ...2 2 5 3 3 1 A B C 3 4 5 2 1 6 2 1 7 5 6 D 8 D 5...

Page 6: ...9 9 1 9 2 10 11 12 12 1 13 12 9 E 8 7 K L M F G 10 11 D 6...

Page 23: ......

Page 25: ......